Flame retardant distribution box

A technology for distribution boxes and flame-retardant layers, which is applied to electrical components, substation/switch layout details, fire rescue, etc., can solve problems such as economic loss, diffusion, and combustion, and achieve improved safety, simple manufacturing process, and low manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

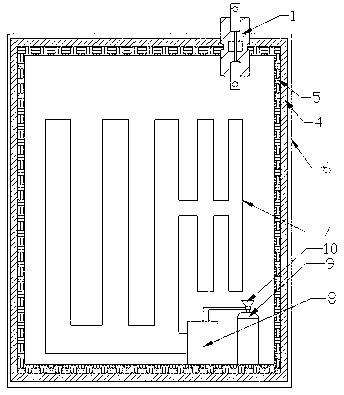

[0022] Do further description below in conjunction with accompanying drawing:

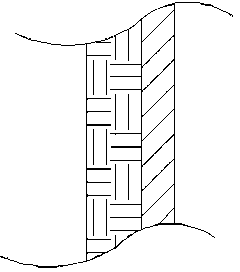

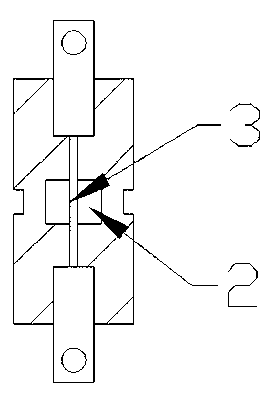

[0023] like Figure 1~2 As shown, the flame-retardant distribution box includes a casing 6, a heat-insulating layer 4, a flame-retardant layer 5, and a flame-retardant joint 1. The heat-insulating layer 4 and the flame-retardant layer 5 are attached to the casing 6 of the distribution box in sequence from outside to inside. Above, the shell is provided with a flame retardant joint 1, the flame retardant joint 1 is made of ceramic material and penetrates through the heat insulation layer 4, the flame retardant layer 5 and the shell 6, and a conductor is arranged in the middle of the flame retardant joint 1, connecting the inside and outside of the distribution box The two sides of the conductor are copper wires, and the middle part is the fuse body 3. At the same time, a cavity 3 is provided at the position of the fuse body 3 inside the flame-retardant joint 1 to provide a fusing space for the fuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com