Built-in floating ball valve

A kind of floating ball valve, built-in technology, applied in the field of floating ball valve, can solve the problems of loose closing, short service life, inconvenient installation and use, etc., and achieve the effect of overcoming the tight closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

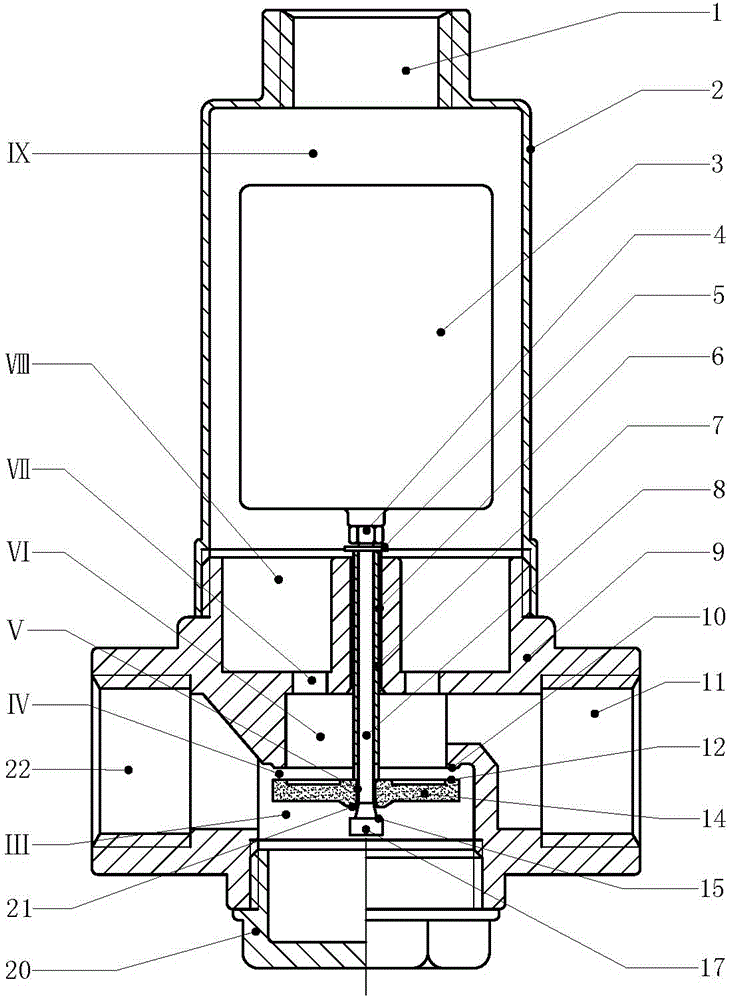

[0014] Embodiment 1 Attached figure 1In the shown embodiment, the first type of built-in float valve is mainly composed of valve body (9), main valve plate (14), pressure relief valve core (17), float ball (3) and valve housing (2). Among them, the valve body (9) has an upper valve chamber (Ⅵ), a lower valve chamber (Ⅲ), a center slideway (6) and a sealing surface a (10), an upper valve chamber (Ⅵ) and a lower valve chamber (Ⅲ) It is a cylindrical space, the upper valve chamber (Ⅵ) is above the lower valve chamber (Ⅲ), the section of the upper valve chamber (Ⅵ) is smaller than the section of the lower valve chamber (Ⅲ), and the sealing surface a (10) is on the top of the upper valve chamber (Ⅲ) ), the center slideway (6) is in the center of the top wall of the upper valve chamber (Ⅵ); the main valve plate (14) is a disc structure, and the main valve plate (14) has a center through hole, The sealing surface d (21), the ring bayonet and the rubber pad a (13), the through hole i...

Embodiment 2

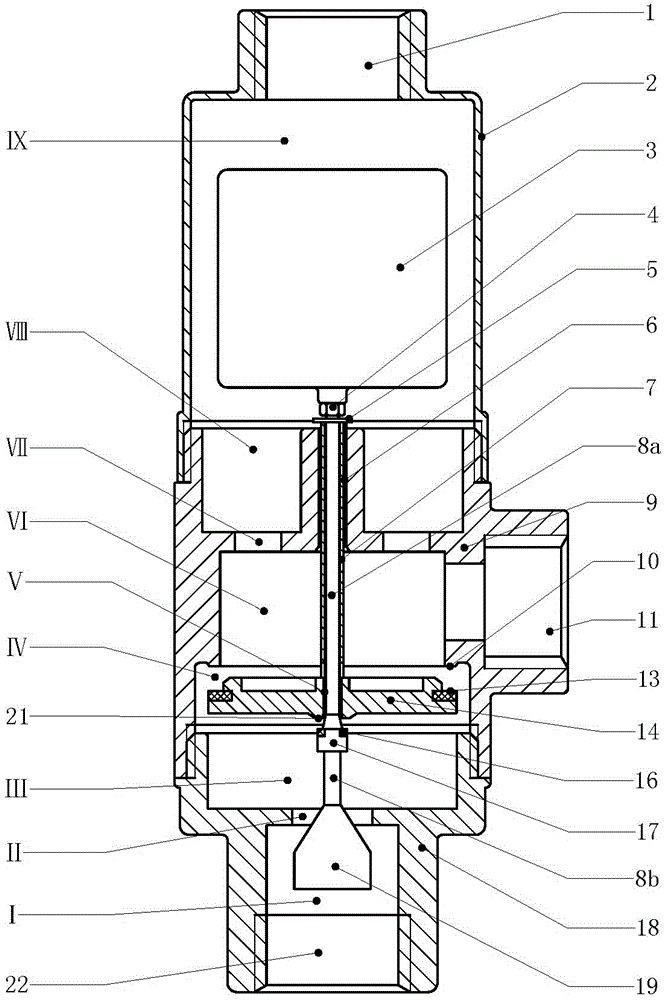

[0015] Embodiment 2 Attached figure 2 In the shown embodiment, the second built-in float valve of the present invention is characterized in that the float valve is mainly composed of a valve body (9), a main valve plate (14), a pressure relief valve core (17), a float ball (3 ) and the valve housing (2), wherein the valve housing (2) is connected to the upper end of the valve body (9), and the inner space of the upper end of the valve housing (2) and the valve body (9) constitutes the water chamber (Ⅷ), the water chamber The upper space of (Ⅷ) is connected to the exhaust port (1), and the floating ball (3) is set in the water chamber (Ⅷ); the valve body (9) has an upper valve chamber (Ⅵ) and a lower valve chamber (Ⅲ) , the center slideway (6) and the sealing surface a (10), the upper valve chamber (Ⅵ) and the lower valve chamber (Ⅲ) form a cylindrical space, the upper valve chamber (Ⅵ) is above the lower valve chamber (Ⅲ), the upper valve chamber The section of chamber (Ⅵ) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com