Efficient cabling device for flexible communication cables

A cable and cabling technology, used in communication cables, cables, insulated cables, etc., can solve the problem of unrounded cables, and achieve the effect of avoiding the phenomenon of turning over, solving the problem of unrounding, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

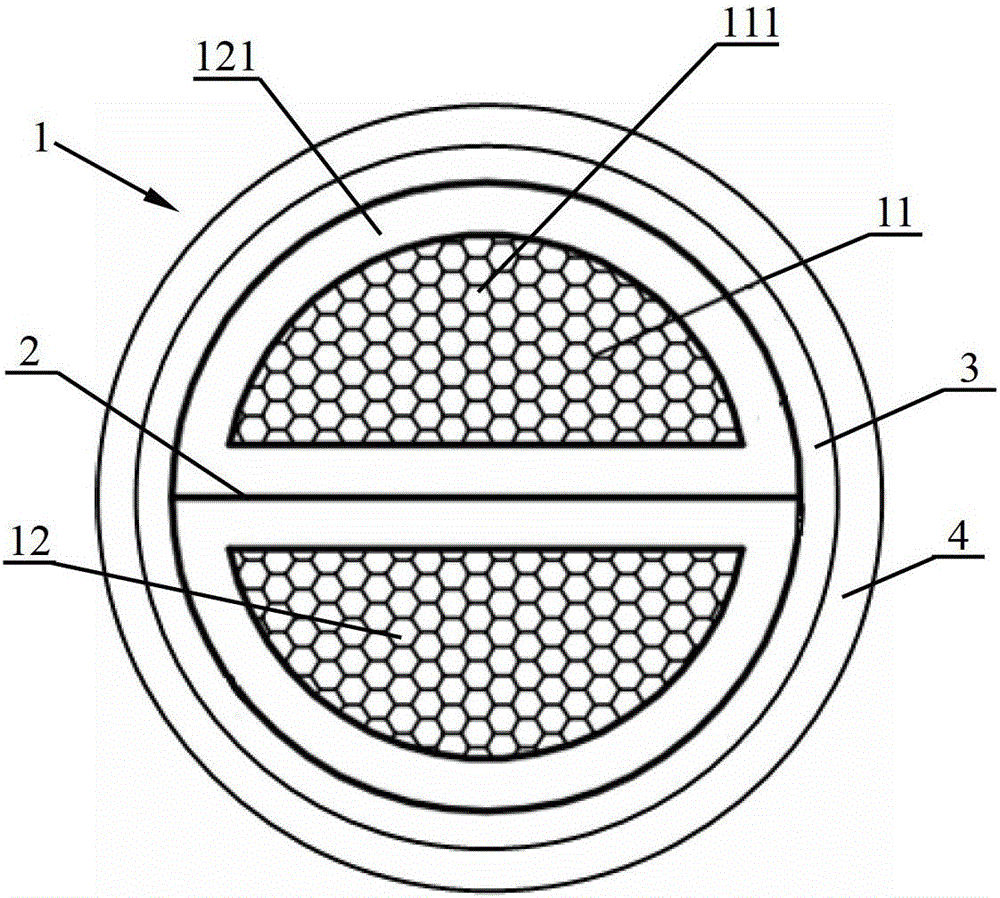

[0029] Embodiment 1: A high-efficiency cabling device for a flexible communication cable, the flexible communication cable 1 respectively includes at least one first semicircular copper conductor 11 twisted by several copper strands 111 and pressed by a mold , the second semicircular copper conductor 12, the outer surfaces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 are coated with an insulating layer 121; the first semicircular copper conductor 11, the second semicircular copper conductor 12 The respective end surfaces of the two semicircular copper conductors 12 contact each other to form a circular wire pair 2, a polyester tape 3 is wrapped around the outer surface of the circular wire pair 2, and a sheath layer 4 is extruded on the polyester tape 3 The outer surface;

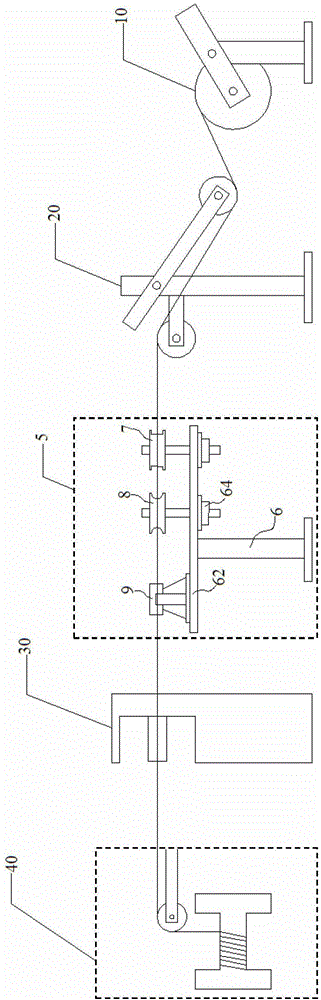

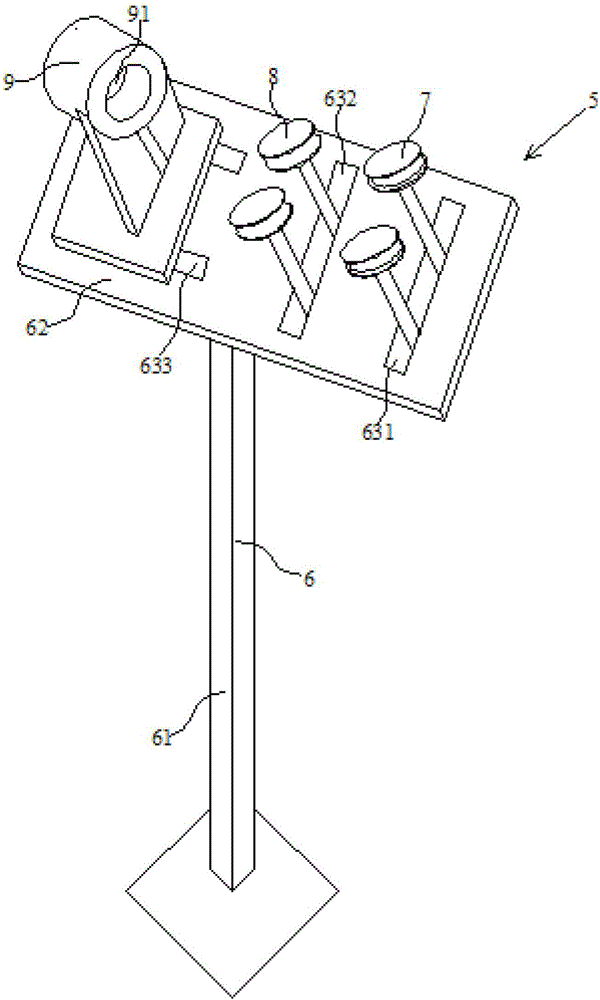

[0030] The high-efficiency cabling device includes 2 sets of pay-off frames 10, 2 sets of tension rods 20, a positioning device 5, a wrapping mechanism 30 an...

Embodiment 2

[0043] Embodiment 2: A high-efficiency cabling device for a communication flexible cable, the communication flexible cable 1 respectively includes at least one first semicircular copper conductor 11 twisted by several copper strands 111 and pressed by a mold , the second semicircular copper conductor 12, the outer surfaces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 are coated with an insulating layer 121; the first semicircular copper conductor 11, the second semicircular copper conductor 12 The respective end surfaces of the two semicircular copper conductors 12 contact each other to form a circular wire pair 2, a polyester tape 3 is wrapped around the outer surface of the circular wire pair 2, and a sheath layer 4 is extruded on the polyester tape 3 The outer surface;

[0044] The high-efficiency cabling device includes 2 sets of pay-off frames 10, 2 sets of tension rods 20, a positioning device 5, a wrapping mechanism 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com