Twisting apparatus for communication power supply flexible cable

A communication power supply and flexible cable technology, which is applied to communication cables, used to reduce the size of conductors/cables, insulated cables, etc., can solve the problems of communication data soft cables that are not round, so as to avoid turning over phenomenon and stabilize performance Guarantee and avoid the effect of large outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

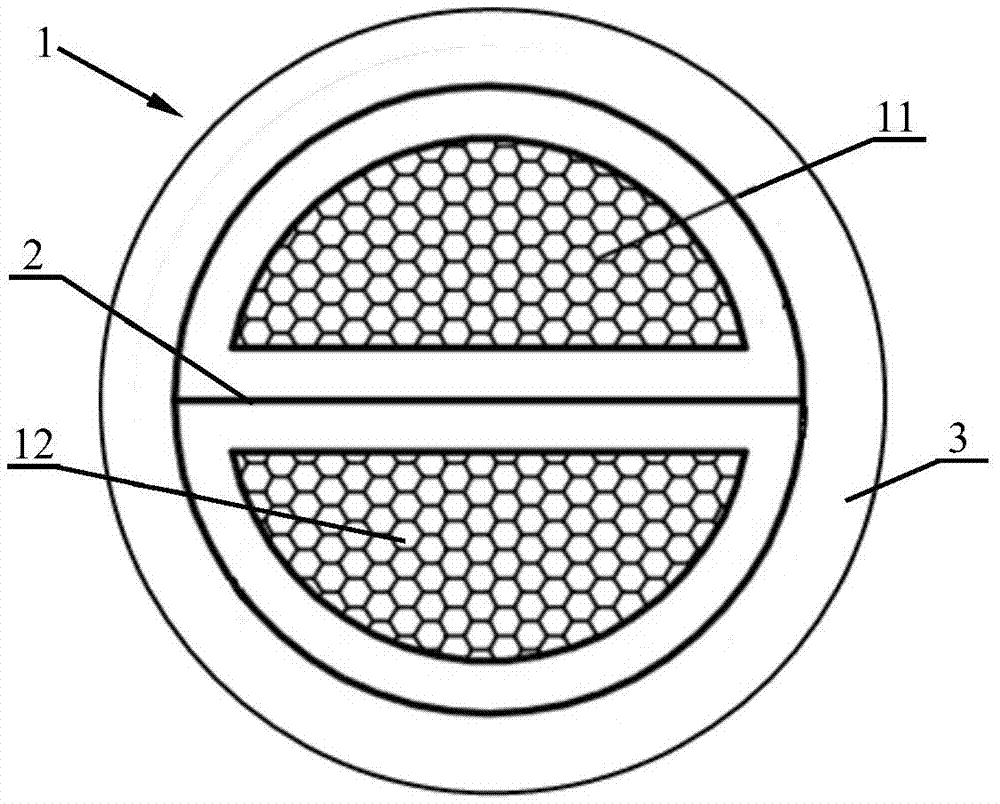

[0028] Embodiment 1: A twisting device for a flexible communication power cable, the flexible communication cable 1 respectively includes at least one first semicircular copper conductor 11 which is twisted by several copper strands and pressed by a mold , the second semicircular copper conductor 12, the respective end faces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 contact to form a circular pair 2, and a sheath layer 3 is extruded on the circular shape line pair 2;

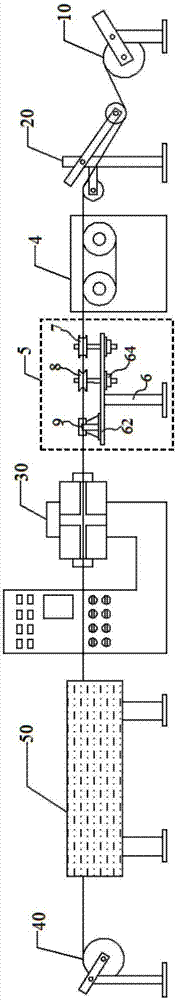

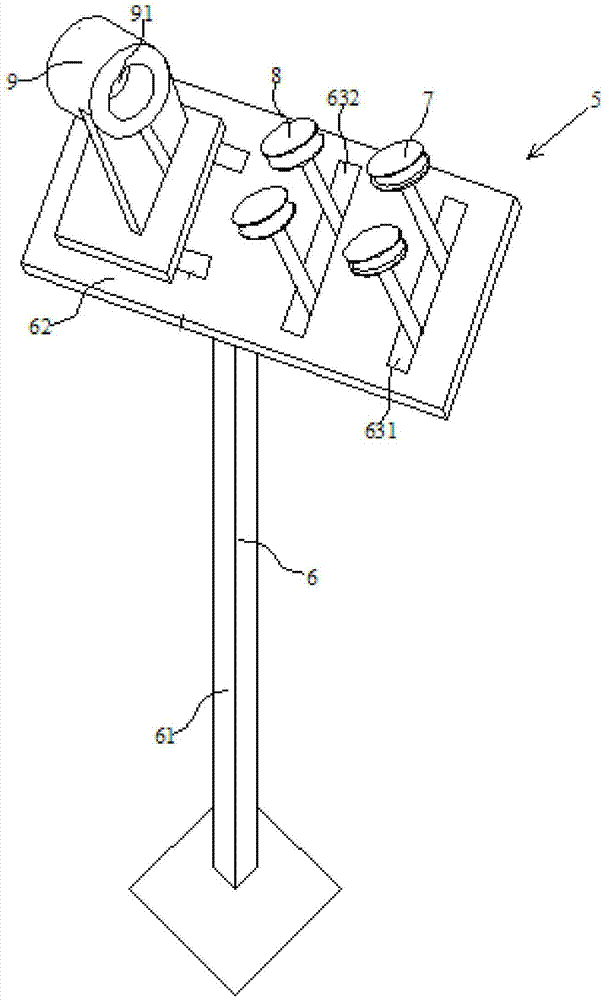

[0029] The high-efficiency stranding device includes 2 sets of pay-off frames 10, 2 sets of tension rods 20, a front traction device 4, a positioning device 5, an extruder 30, a cooling water tank 50 and a take-up frame 40;

[0030] One group of the 2 groups of pay-off racks 10 for releasing wires is used to store the first semicircular copper conductor 11, and the other group is used to store the second semicircular copper conductor 12;

[0031] The two group...

Embodiment 2

[0041] Embodiment 2: A twisting device for a flexible communication power cable, the flexible communication cable 1 respectively includes at least one first semicircular copper conductor 11 which is twisted by several copper strands and pressed by a mold , the second semicircular copper conductor 12, the respective end faces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 contact to form a circular pair 2, and a sheath layer 3 is extruded on the circular shape line pair 2;

[0042] The high-efficiency stranding device includes 2 sets of pay-off frames 10, 2 sets of tension rods 20, a front traction device 4, a positioning device 5, an extruder 30, a cooling water tank 50 and a take-up frame 40;

[0043] One group of the 2 groups of pay-off racks 10 for releasing wires is used to store the first semicircular copper conductor 11, and the other group is used to store the second semicircular copper conductor 12;

[0044] The two group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com