Double-wheel spinning die and machining process thereof

A mold and double-wheel technology, which is applied to household appliances, other household appliances, hollow objects, etc., can solve the problems of wasting materials, increasing the difficulty of post-sequence thread rolling or rolling, etc., to reduce costs, improve material utilization, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

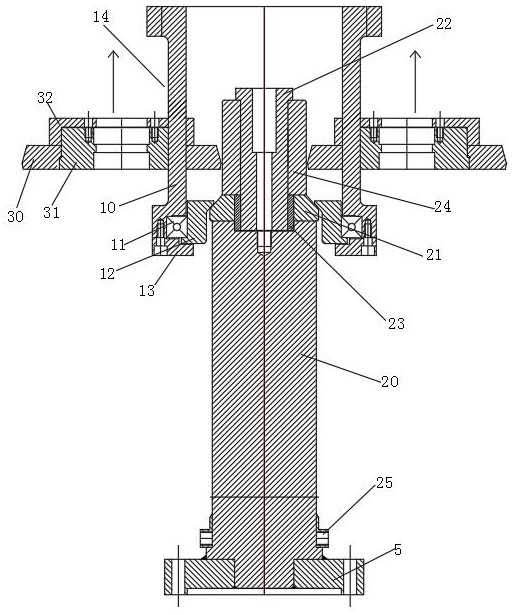

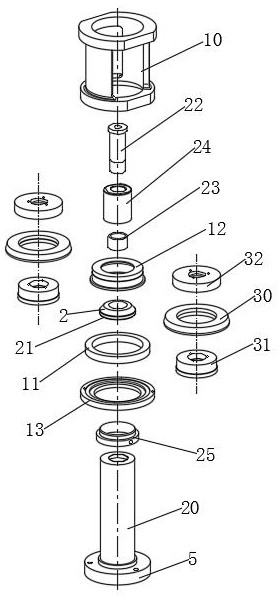

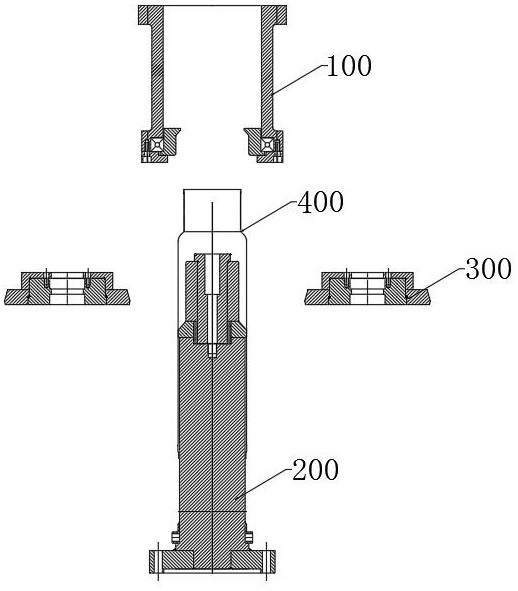

[0024] In order to make the technical solution of the present invention clearer, the following is combined with the appendix Figure 1-3 , the present invention will be described in detail. It should be understood that the specific embodiments described in this specification are only for explaining the present invention, but not for limiting the protection scope of the present invention.

[0025] A double-wheel spinning die, comprising an upper die assembly 100, a lower die assembly 200 and a spinning assembly 300; the upper die assembly 100 is fixed on the upper die, and is driven by the upper die drive mechanism to move up and down along the axis ; The lower mold assembly 200 is fixed on the lower mold, and is driven by the lower mold driving mechanism to rotate around the axis, and the blank is arranged on the lower mold assembly 200 and rotates with the lower mold assembly 200; the blank can pass through The process of cutting the tube-swelling forming-cutting and dividin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com