Processing apparatus of flexible cable for supplying power to mobile device

一种加工装置、移动设备的技术,应用在电缆/导体制造、电路、电气元件等方向,能够解决线缆不圆整、减小应力等问题,达到避免翻身现象、稳定性能保证、避免外径偏大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

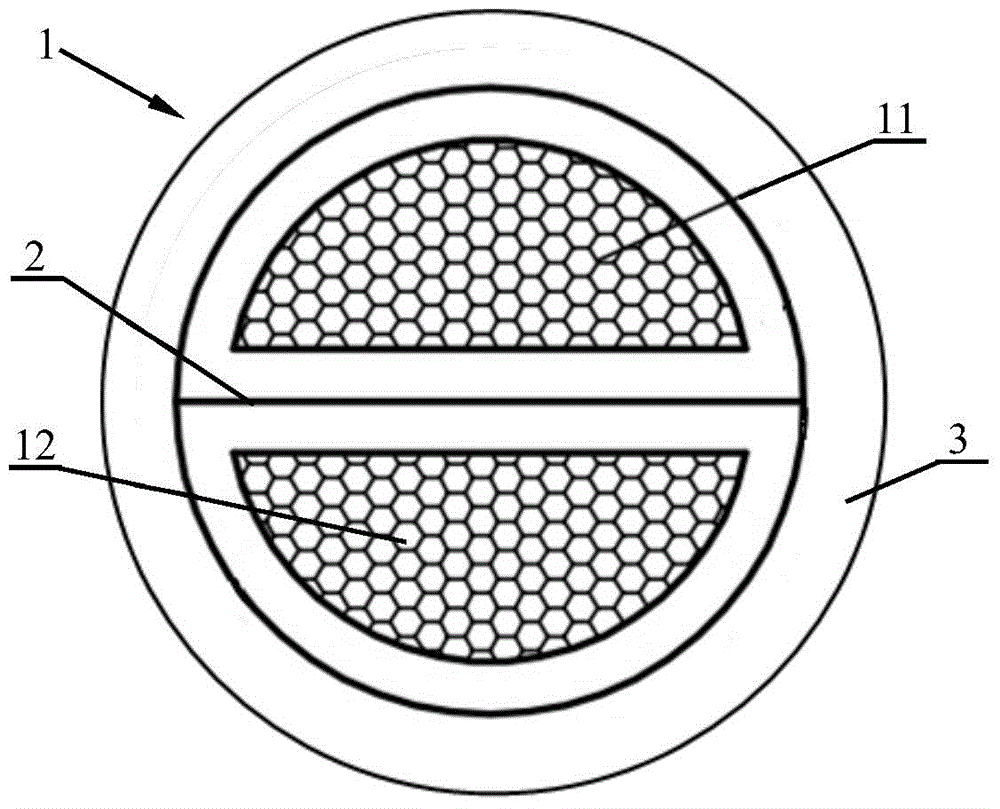

[0031] Embodiment 1: A processing device for a flexible cable used for power supply of mobile equipment, the communication flexible cable 1 respectively includes at least one first semicircular copper conductor twisted by several copper strands and pressed by a mold 11. The second semicircular copper conductor 12, the respective end faces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 are in contact to form a circular wire pair 2, and a sheath layer 3 is extruded on the said circular pair 2;

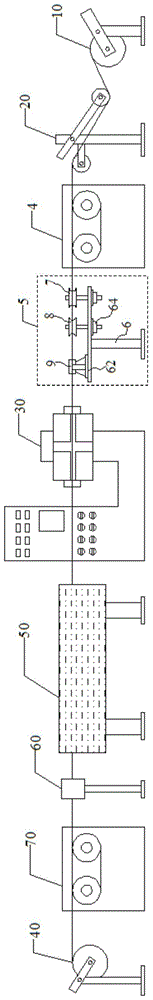

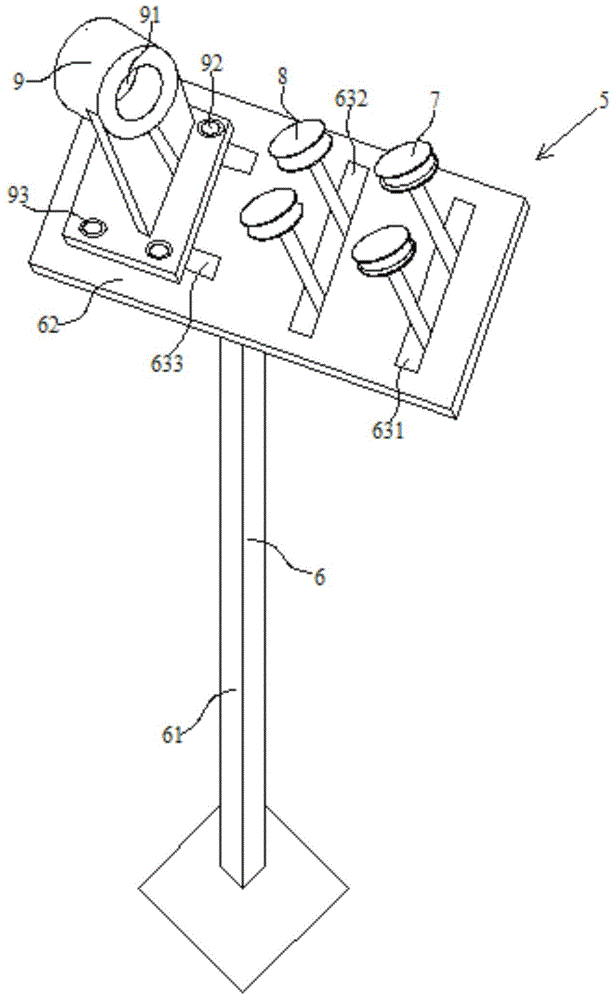

[0032] The processing equipment includes 2 sets of pay-off racks 10, 2 sets of tension rods 20, front traction device 4, positioning device 5, extruder 30, cooling water tank 50, drying mechanism 60, rear traction mechanism 70 and wire take-up frame 40 ;

[0033] One group of the 2 groups of pay-off racks 10 for releasing wires is used to store the first semicircular copper conductor 11, and the other group is used to store the second semic...

Embodiment 2

[0048] Embodiment 2: A processing device for a flexible cable used for power supply of mobile equipment, the communication flexible cable 1 respectively includes at least one first semicircular copper conductor twisted by several copper strands and pressed by a mold 11. The second semicircular copper conductor 12, the respective end faces of the first semicircular copper conductor 11 and the second semicircular copper conductor 12 are in contact to form a circular wire pair 2, and a sheath layer 3 is extruded on the said circular pair 2;

[0049] The processing equipment includes 2 sets of pay-off racks 10, 2 sets of tension rods 20, front traction device 4, positioning device 5, extruder 30, cooling water tank 50, drying mechanism 60, rear traction mechanism 70 and wire take-up frame 40 ;

[0050] One group of the 2 groups of pay-off racks 10 for releasing wires is used to store the first semicircular copper conductor 11, and the other group is used to store the second semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com