An automatic rope hoist for a wire rope traction type freight machine

A technology of steel wire rope and freight machine, which is applied in the production and transportation field of mountain orchards, can solve the problems of wire rope running away from the reel, inconsistent transmission direction, and disorderly winding of wire rope, and achieves the effect of solving displacement and gnawing, simple structure and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

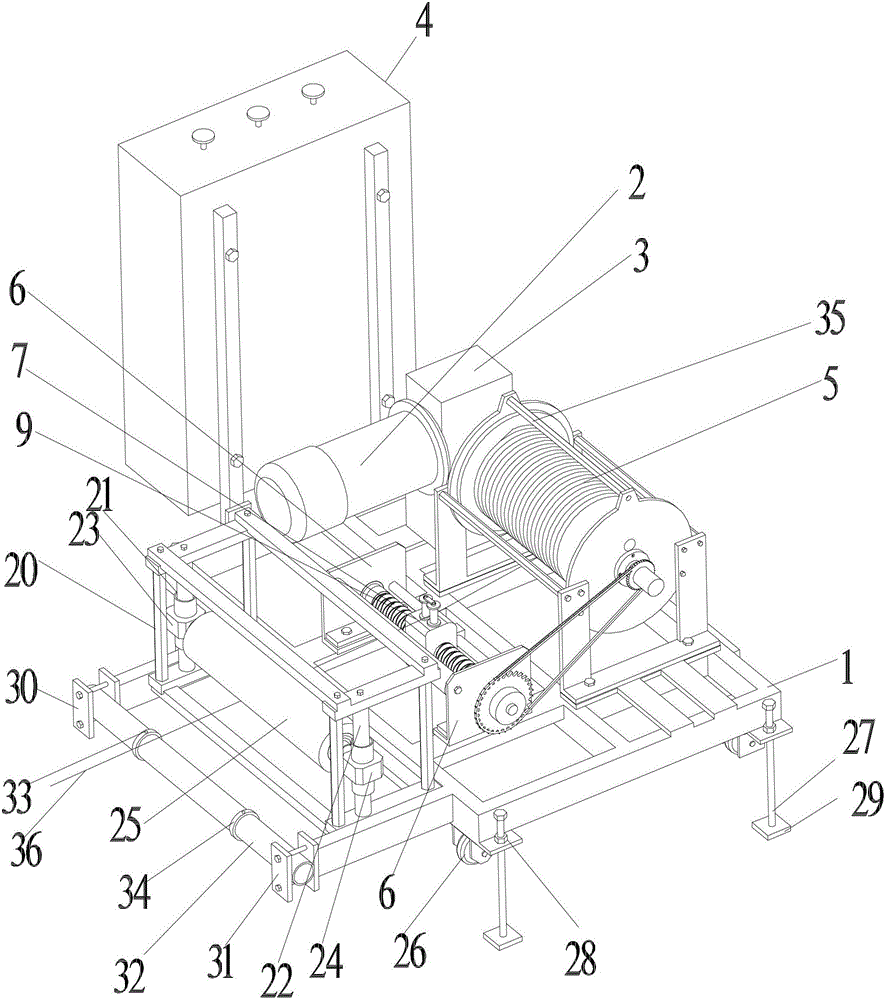

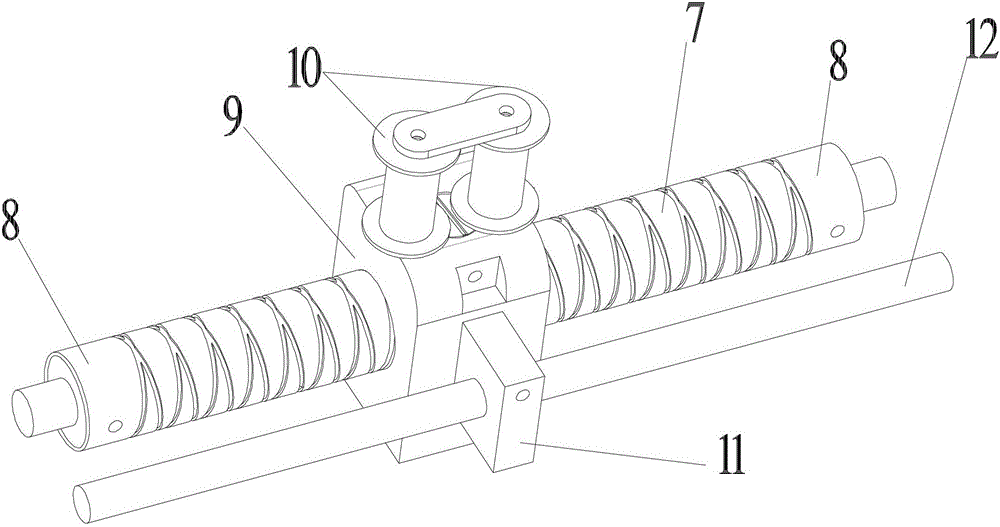

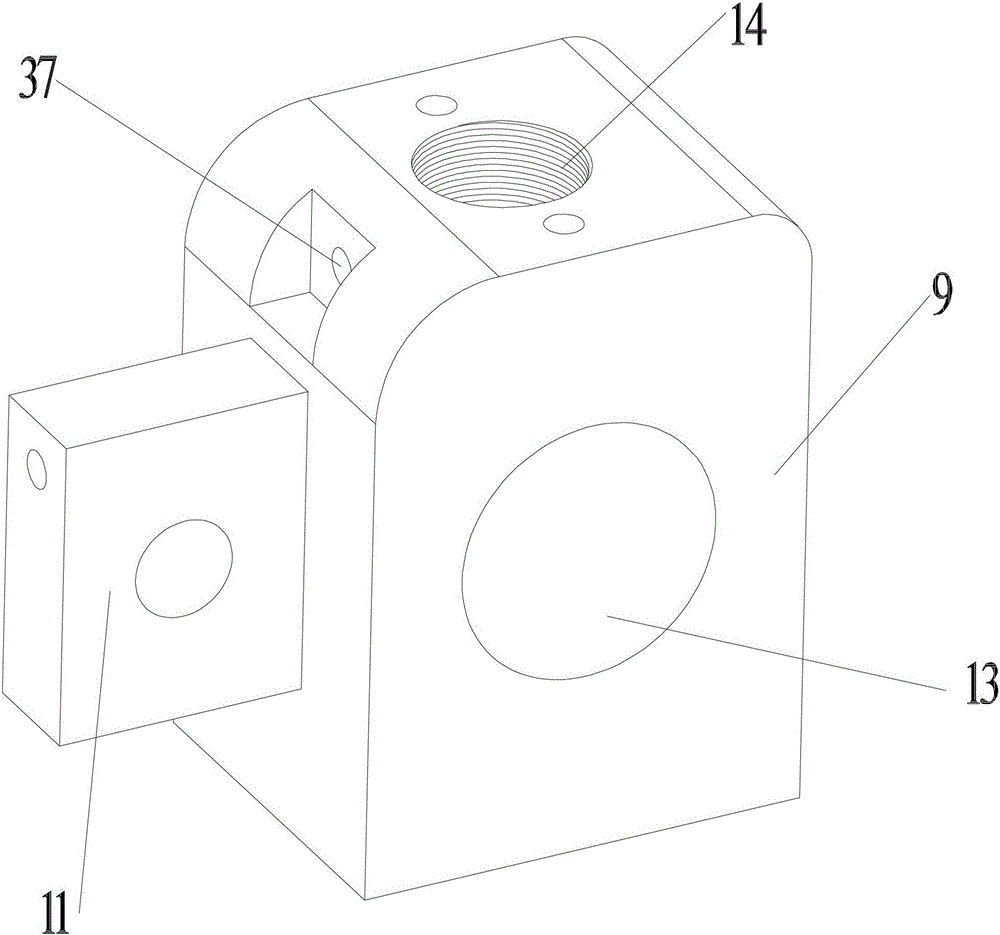

[0039] Such as Figure 1-9 As shown, an automatic rope hoist for a wire rope traction type freight aircraft includes a bracket 1, a motor 2, a reducer 3, a controller 4, a reel 5 and a wire rope guide; wherein, a controller 4 is installed on the bracket 1 to control The device 4 is connected with the motor 2 on the bracket 1, the motor 2 is connected with the reducer 3, the reducer 3 drives the reel 5, and a wire rope guide device is arranged in front of the reel 5 so that the wire rope 36 is wound on the reel 5 in an orderly manner. The cylinder 5 is linked with the wire rope guiding device. Controller 4 in the present embodiment comprises control box, and PLC is arranged in the control box, and control box button is set on the upper surface of control box, in order to be convenient to move and be convenient to fixed work, four jiaos of support 1 are provided with moving wheel 26 and support support mechanism, support support The mechanism includes a support screw 27, a tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com