Method and device for detecting verticality of rotating shaft

A detection method and verticality technology, which is applied in the field of detection of the verticality of the rotating shaft, can solve the problems of inability to measure directly and quickly, and require high working conditions, and achieve the effect of low price, good adaptability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

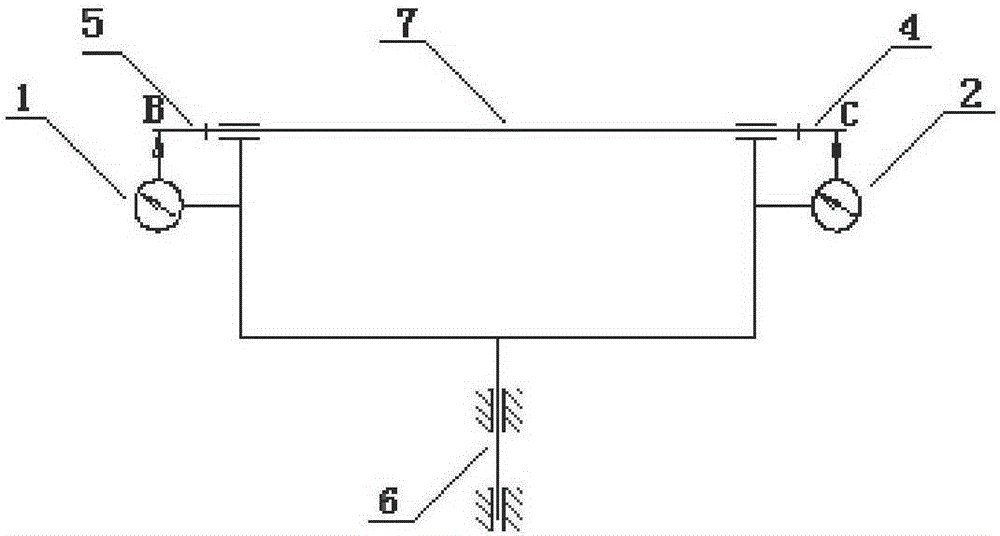

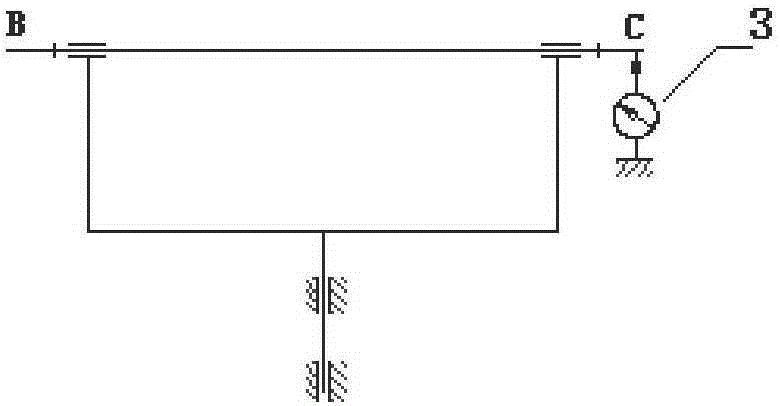

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A method for detecting the verticality of the rotating shaft in this embodiment, the I-axis and the II-axis in the present invention are any two vertical axes on the turntable, and there is no order, and can be used for both two-axis turntables and three-axis or more axis turntables.

[0028] First, grind two mandrels, and install the mandrels on both sides of the turntable II shaft as the lead-out end of II;

[0029] Secondly, use a screw micrometer to measure the roundness error of the lead-out ends on both sides of the turntable II axis, and record the data;

[0030] Then, use a dial indicator to measure the circular runout of the turntable II axis, and record the data; rotate the turntable I axis, use a dial indicator to measure the change value of the lead-out mandrel on both sides of the turntable II axis, and record the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com