Method and device for measuring axial force of thread fastening member

A technology for threaded fasteners and measuring devices, which can be used to measure torque/torsional force and other directions during tightening, and can solve problems such as low measurement accuracy and inability to obtain the true value of bolt axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

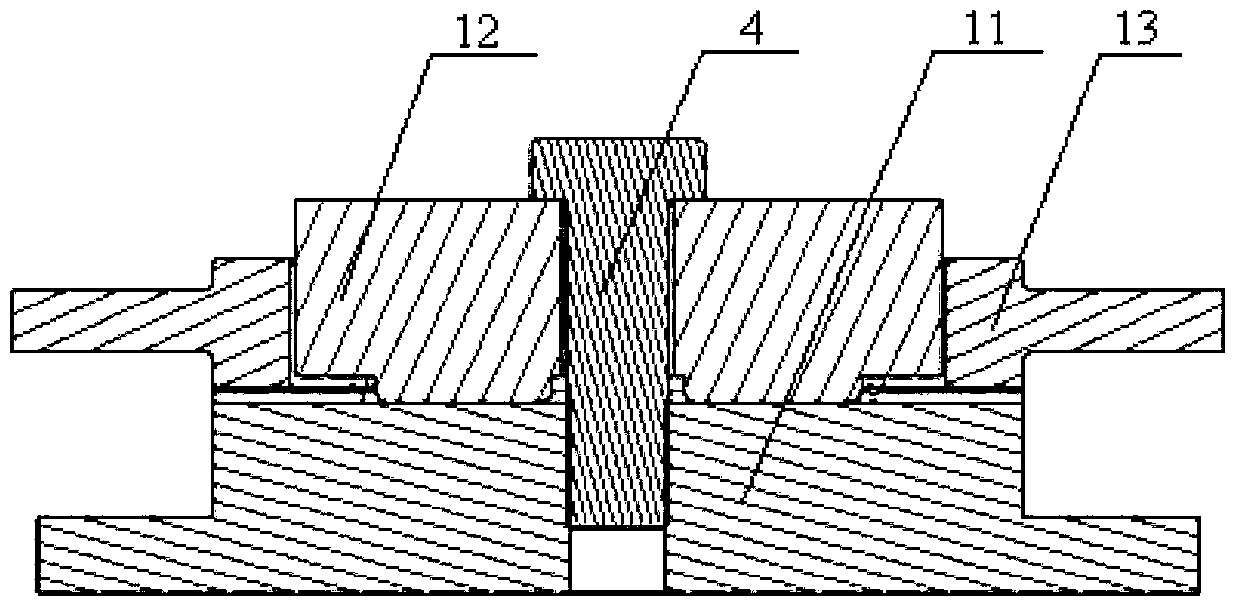

[0041] The core of the present invention is to provide a threaded fastener axial force measurement method and measuring device to accurately measure the axial force of the threaded fastener in the elastic / plastic range, thereby providing data support for the theoretical research on the reliability design of threaded connections , and then guide the design and assembly process to the direction of precise control.

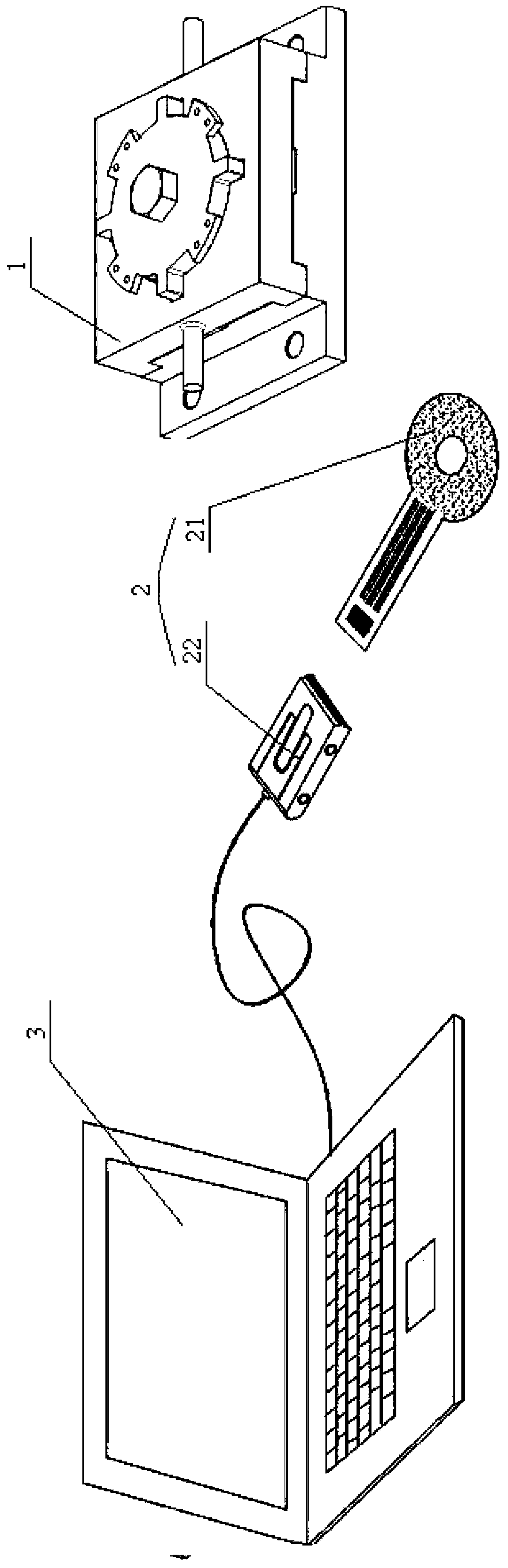

[0042] Without loss of generality, the specific implementation of the threaded fastener measuring method and measuring device provided by the present invention will be described below by taking the measurement of the axial force of a bolt during actual use as an example in conjunction with the accompanying drawings.

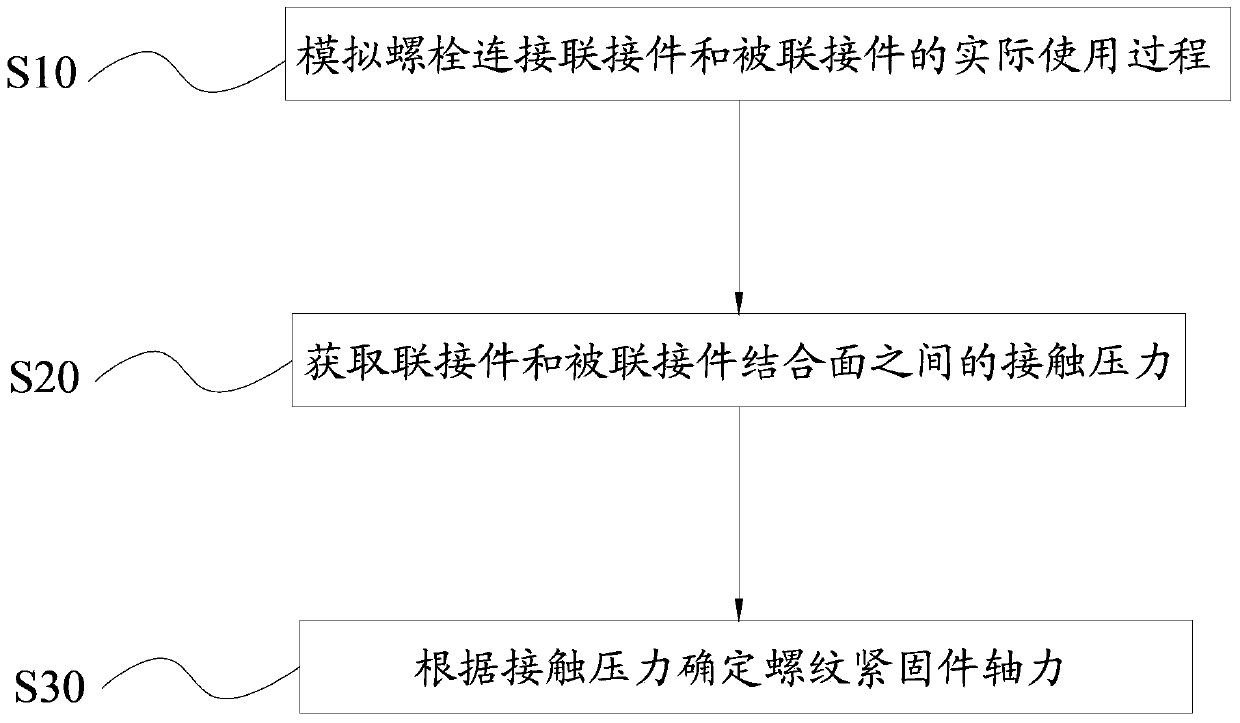

[0043] See figure 1 , figure 1 A flow chart of the method for measuring the axial force of a threaded fastener in a specific embodiment is shown.

[0044] Such as figure 1 As shown, the method for measuring the axial force of threaded fasteners provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com