Thermal resistance testing method and thermal resistance testing device

A test method and technology of a test device, applied in the field of testing, can solve the problems of inaccurate testing, failure to consider the heat dissipation problem of triodes and heat sinks, and achieve the effect of improving test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

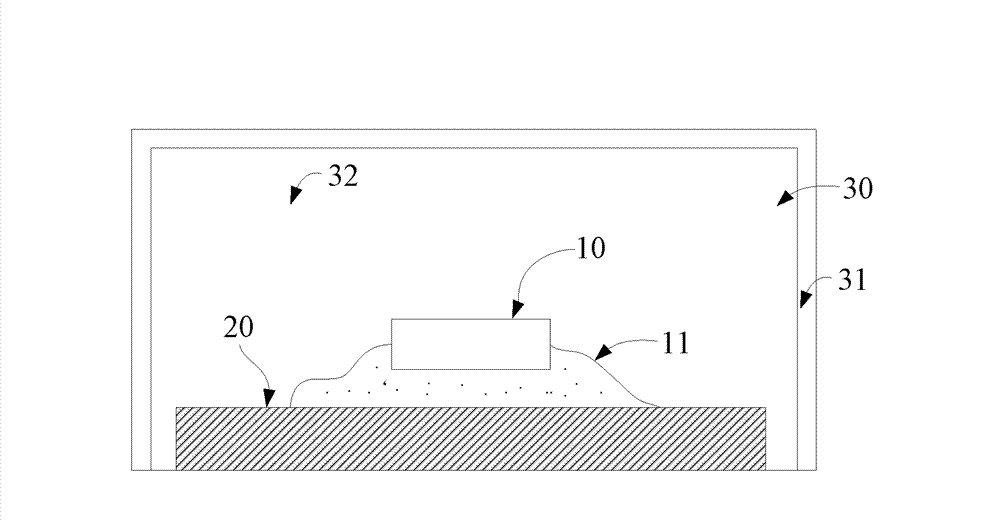

[0040] Under the preferred embodiment, as figure 2 As shown, the heat insulation component 30 includes a heat insulation shell 31 with a unidirectional opening, and the opening of the heat insulation shell 31 is used to form a unidirectional heat conduction channel 100 for conducting heat generated by the heating component 10 in one direction.

[0041]Preferably, the heat insulation component 30 also includes a heat insulation filling material 32 filled in the gap between the heat insulation shell 31 and the composite heat conducting material 20, continue to refer to figure 2 , the heat insulating filling material 32 is used to further prevent the heat generated by the heating component 10 from being lost to the external environment. In actual application, when there is still a gap between the opening of the heat insulation shell 31 and the heat insulation filling material 32, it should also be understood that the gap is filled with the heat insulation filling material 32 to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap