Building formwork

A technology of building templates and side panels, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of uneven buildings, time-consuming and labor-intensive formwork, uneven rows, etc., and achieve the effect of installation and use

Inactive Publication Date: 2013-10-30

DALIAN GANGXIN MACHINERY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing building templates include side frame panels, end frame panels and bottom panels. The side frame panels and end frame panels form a rectangular frame. Both the side frame panels and the end frame panels have connection holes. Since the connection holes are all of the same size When two templates or multiple templates are connected in pairs, the connecting holes on different templates are not easy to align, which is time-consuming and laborious; or the templates are not aligned after the connecting holes are aligned, so that the cast buildings are uneven. together

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

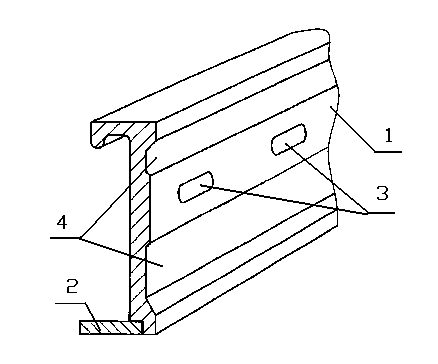

[0010] Such as figure 1 As shown, the building formwork of the present invention includes a side plate 1 and a bottom plate 2, and a waist-shaped connection through hole 3 is provided in the middle of the side plate 2. Parallel grooves 4 are provided above and below the outer side of the side plate 2 . The building formwork is made of cement material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a building formwork which comprises a side plate (1) and a bottom plate (2). The building formwork is characterized in that kidney-shaped connecting through holes (3) are formed in the middle of the side plate (2). Parallel grooves (4) are respectively formed in the outer upper side and the outer lower side of the side plate (2). The building formwork is made of cement materials. The building formwork has the advantages that as the connecting through holes in the side plate are kidney-shaped holes, two building formworks can be easily aligned with each other and inserted into each other when connected with each other by side plates, then fasteners are inserted into the building formworks, and the building formworks are aligned with each other; the building formwork is quite convenient to install and use, and a building which is constructed by means of pouring is flat and neat.

Description

technical field [0001] The invention relates to the field of construction engineering, in particular to a construction formwork. Background technique [0002] Existing building templates include side frame panels, end frame panels and bottom panels. The side frame panels and end frame panels form a rectangular frame. Both the side frame panels and the end frame panels have connection holes. Since the connection holes are all of the same size When two templates or multiple templates are connected in pairs, the connecting holes on different templates are not easy to align, which is time-consuming and laborious; or the templates are not aligned after the connecting holes are aligned, so that the cast buildings are uneven. together. Contents of the invention [0003] In order to overcome the above disadvantages, the present invention provides a formwork for construction which facilitates the insertion of fasteners and the alignment of the formwork. [0004] The technical sol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G9/00

Inventor 白龙浩

Owner DALIAN GANGXIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com