Moving part structure of linear sliding rail

A technology of linear slides and moving parts, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve problems such as loosening, increase the rigidity of the joint, reduce the probability of failure, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

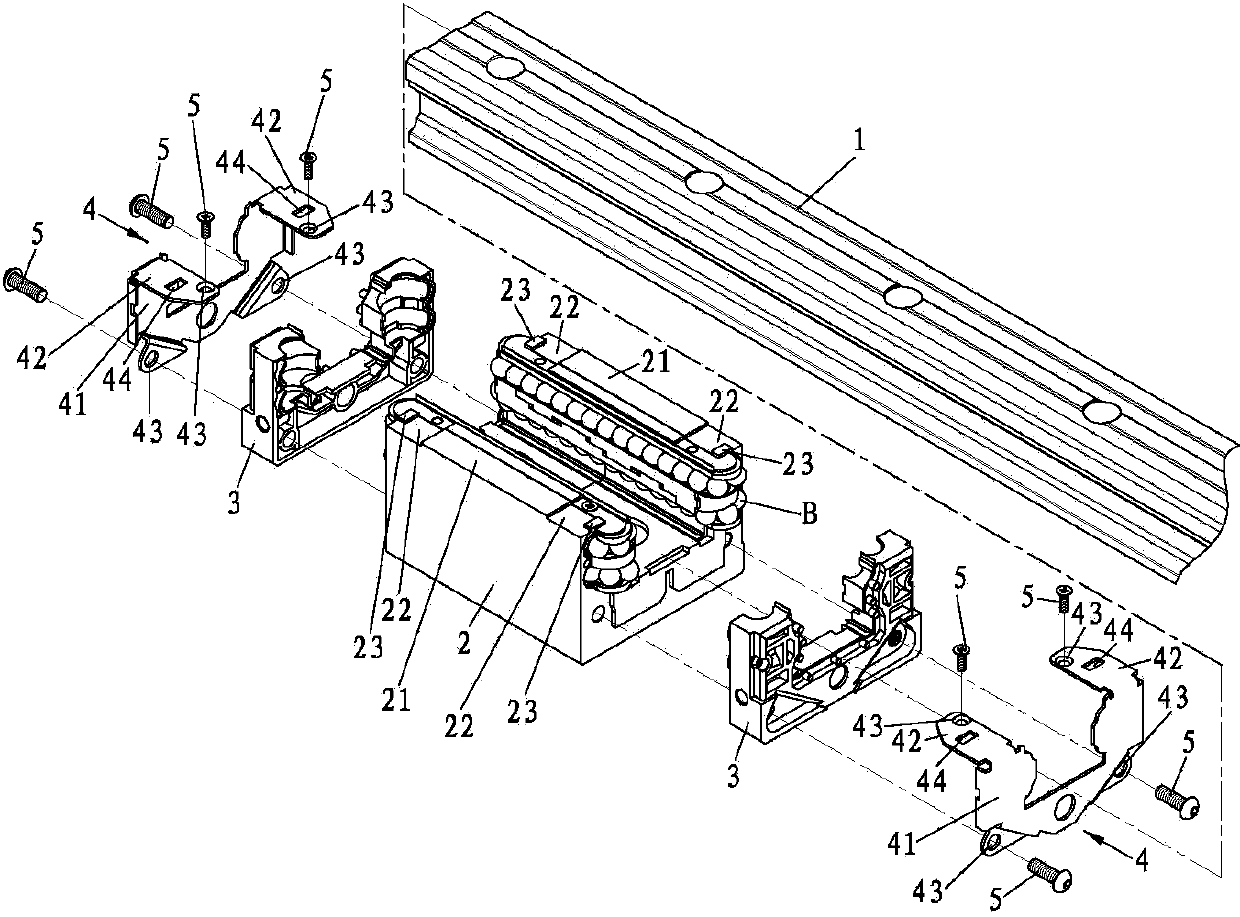

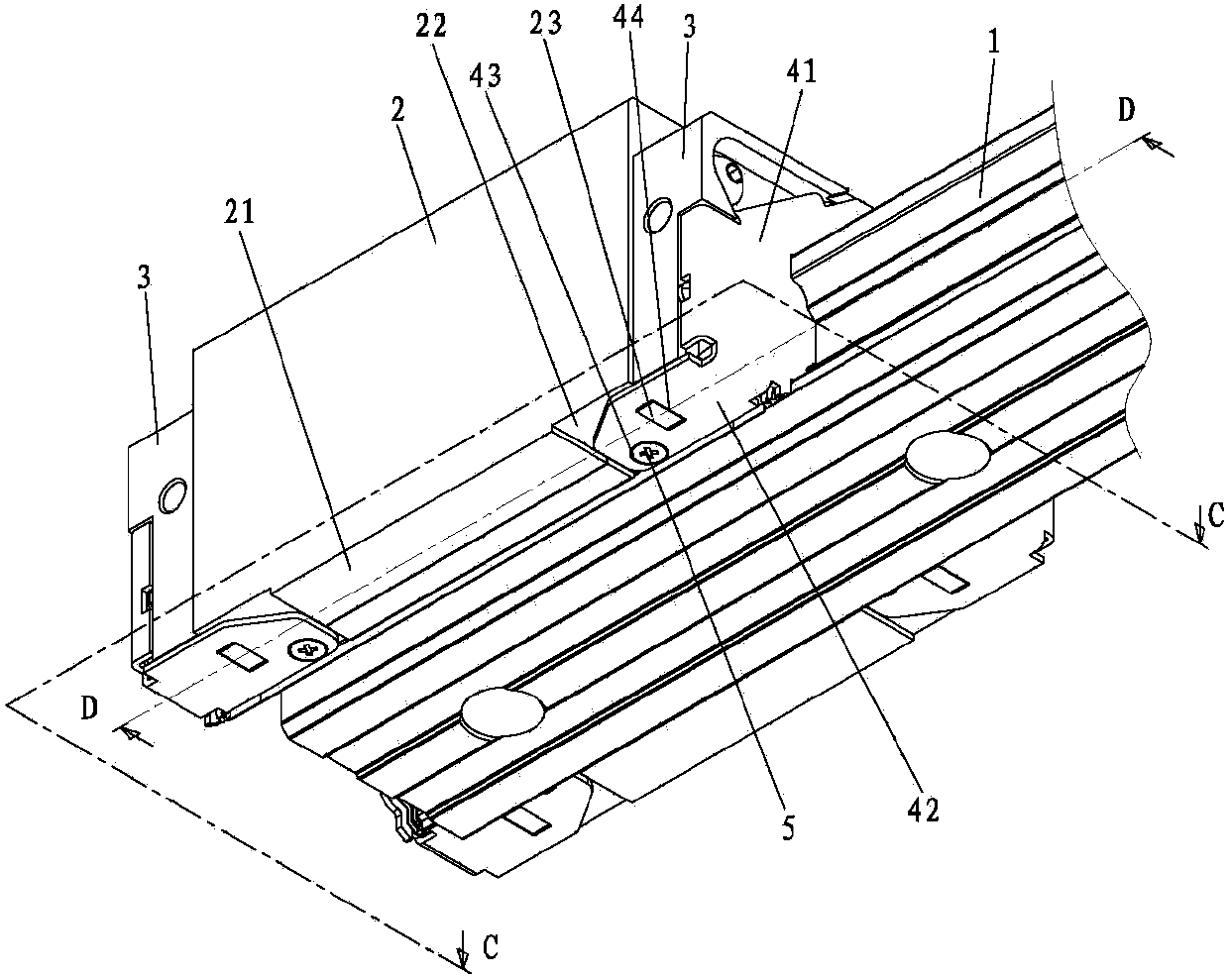

[0036] Please refer to the first embodiment of the present invention figure 1 and figure 2 As shown, this embodiment includes:

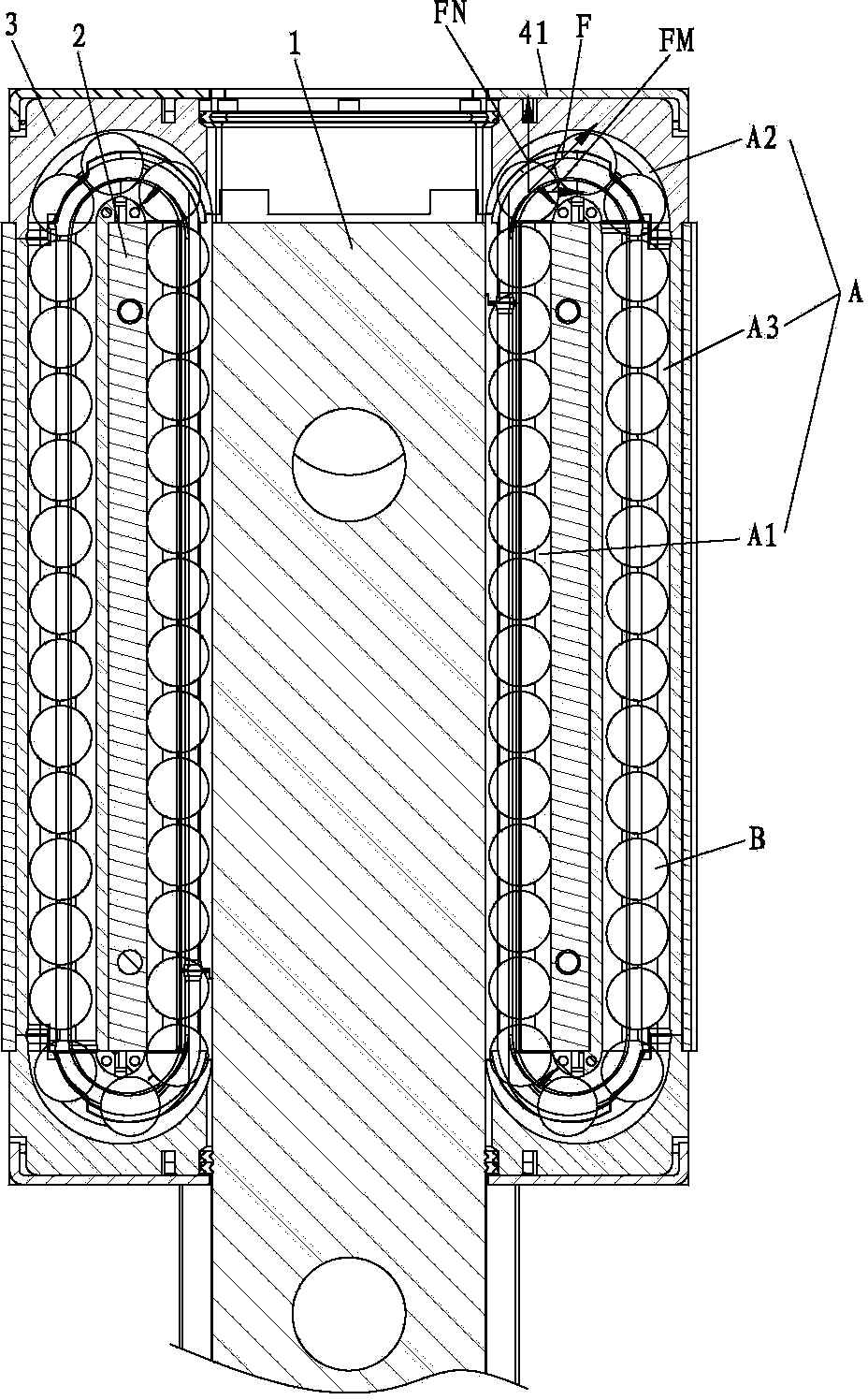

[0037] A sliding rail 1; a sliding seat 2, including two relatively extended legs 21 for straddling the sliding rail 1, a recess 22 is respectively arranged at both ends of each leg 21, and each of the recesses 22 At least one protrusion 23 is provided; two end covers 3 are combined on the opposite ends of the slide seat 2; two reinforcement sheets 4, each reinforcement sheet 4 includes a side plate 41, and two curved edges extending from the side plate 41 Bending extension piece 42, the two bending extension pieces 42 correspond to the recesses 22 on the two feet 21 of the slide seat 2, a fixing hole 43 is respectively arranged on the side plate 41 and the two bending extension pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap