A hole tray seeder

A plug planter and plug tray technology are applied to single-seed planters, planter parts, etc., which can solve the problems of unstable seeding quality, clogging of seed guide pipes, low seeding qualification rate, etc., and achieve stable operation mechanism. Reliable, improve work efficiency, and the effect of reliable structural operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

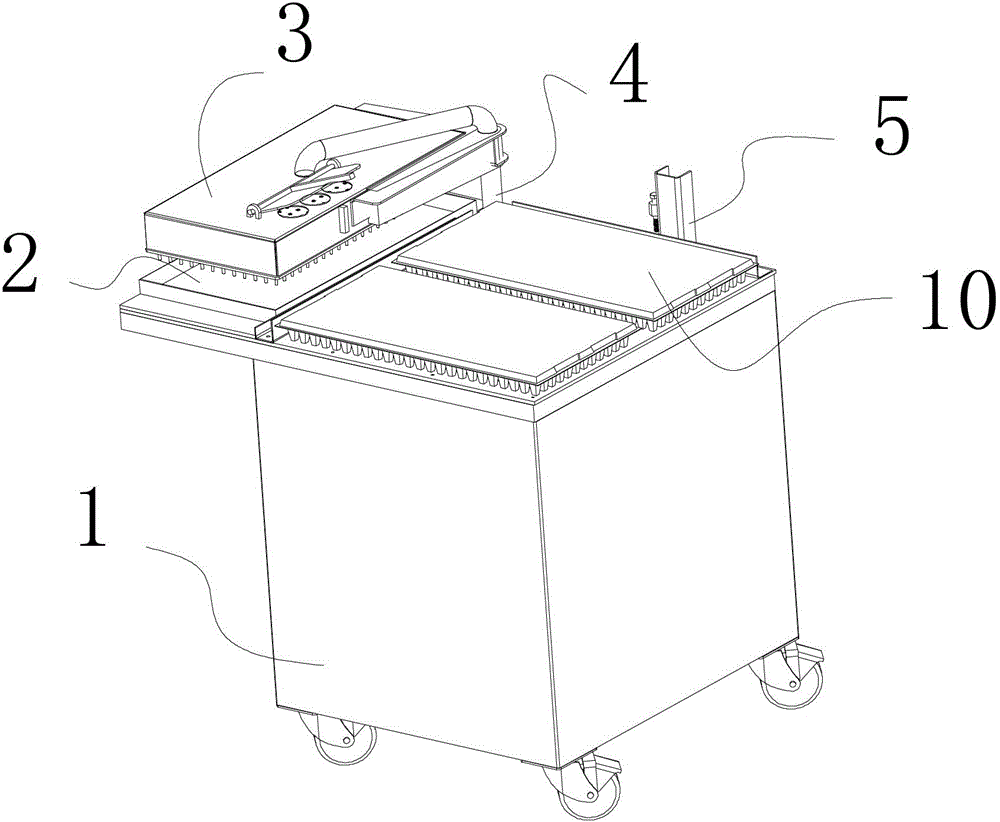

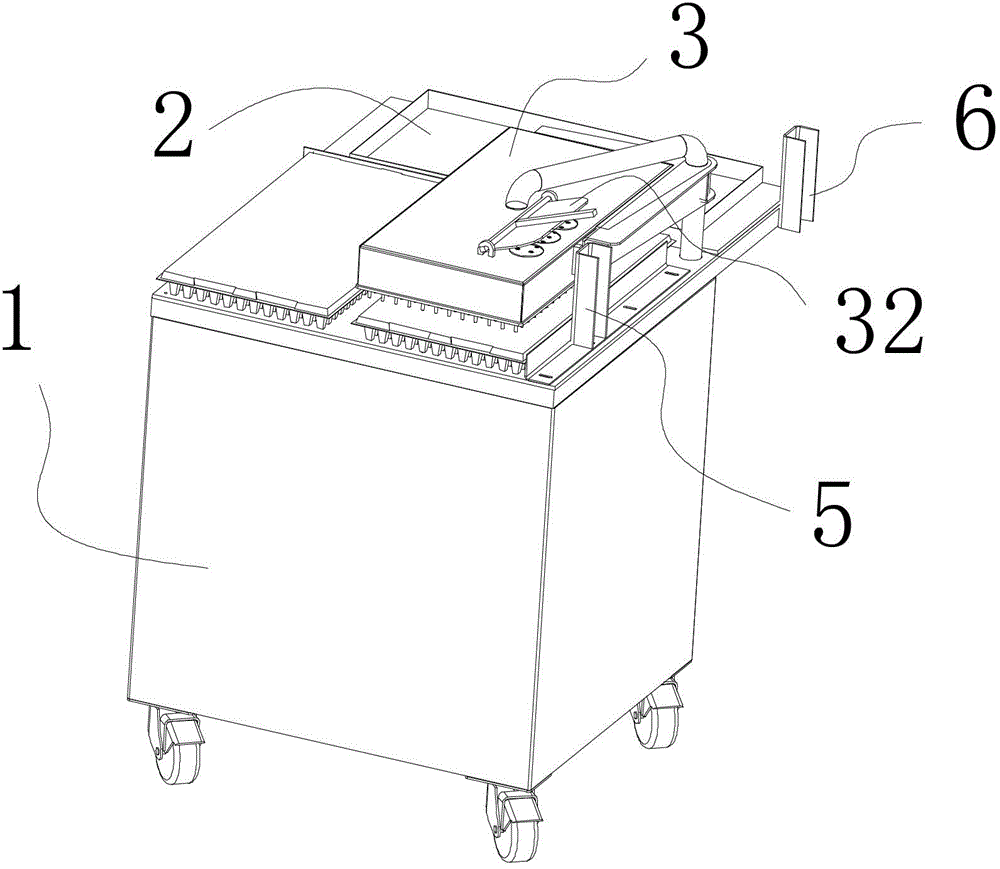

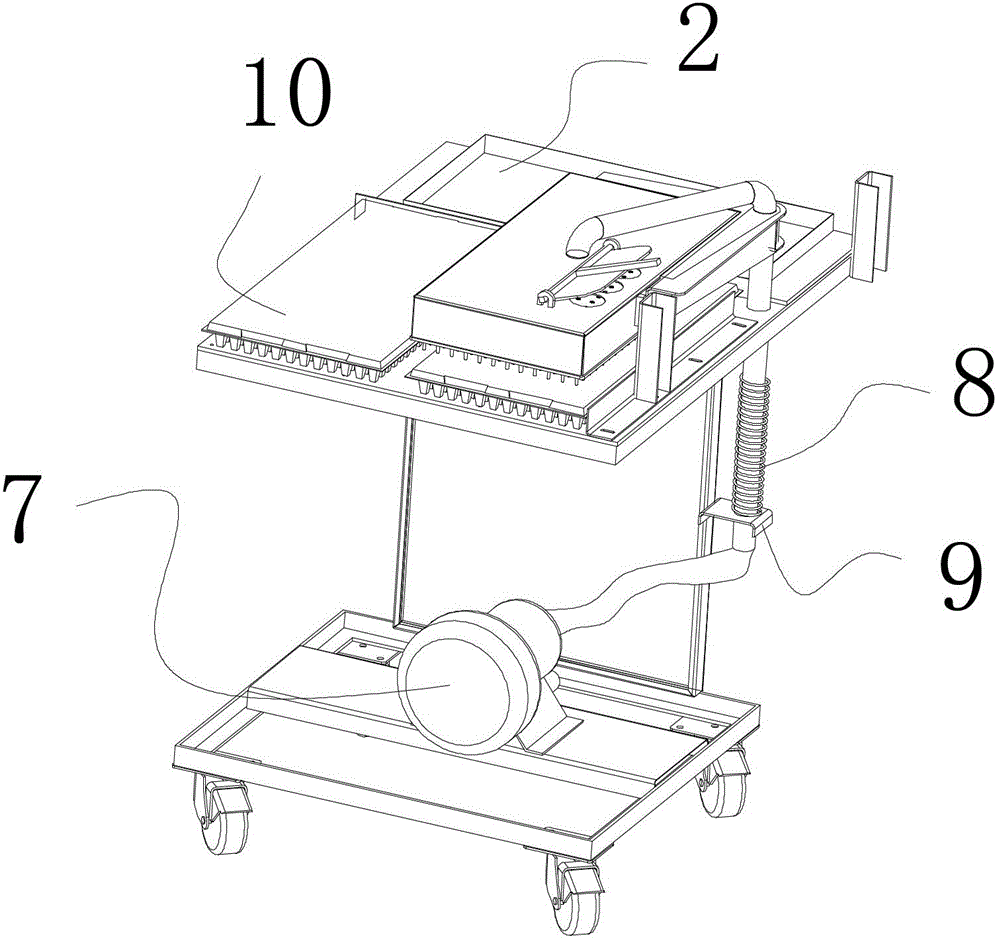

[0046] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0047] Such as Figure 1 to Figure 7 As shown, a plug seeding machine includes a chassis 1, the worktable at the upper end of the cabinet 1 is formed with a plug station for placing the plug 10 and a seed tray station for placing the seed tray 2, and the cabinet 1 is also provided with a reciprocating Seed sucker 3 that moves at the hole tray station and the seed tray station and can move up and down. The bottom surface of the seed sucker 3 is provided with a number of seed sucking holes. Correspondingly, an air pump 7 is arranged in the cabinet 1, and the air pump 7 communicates with the seed suction plate 3 through the suction pipe 4, and the air pressure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com