Method of damage-resistant driving component device and damage-resistant driving component device implementing the same

A driving component and anti-damage technology, applied in the mechanical field, can solve problems such as reducing the service life of equipment, damaging power impact parts, driving mechanisms and other components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

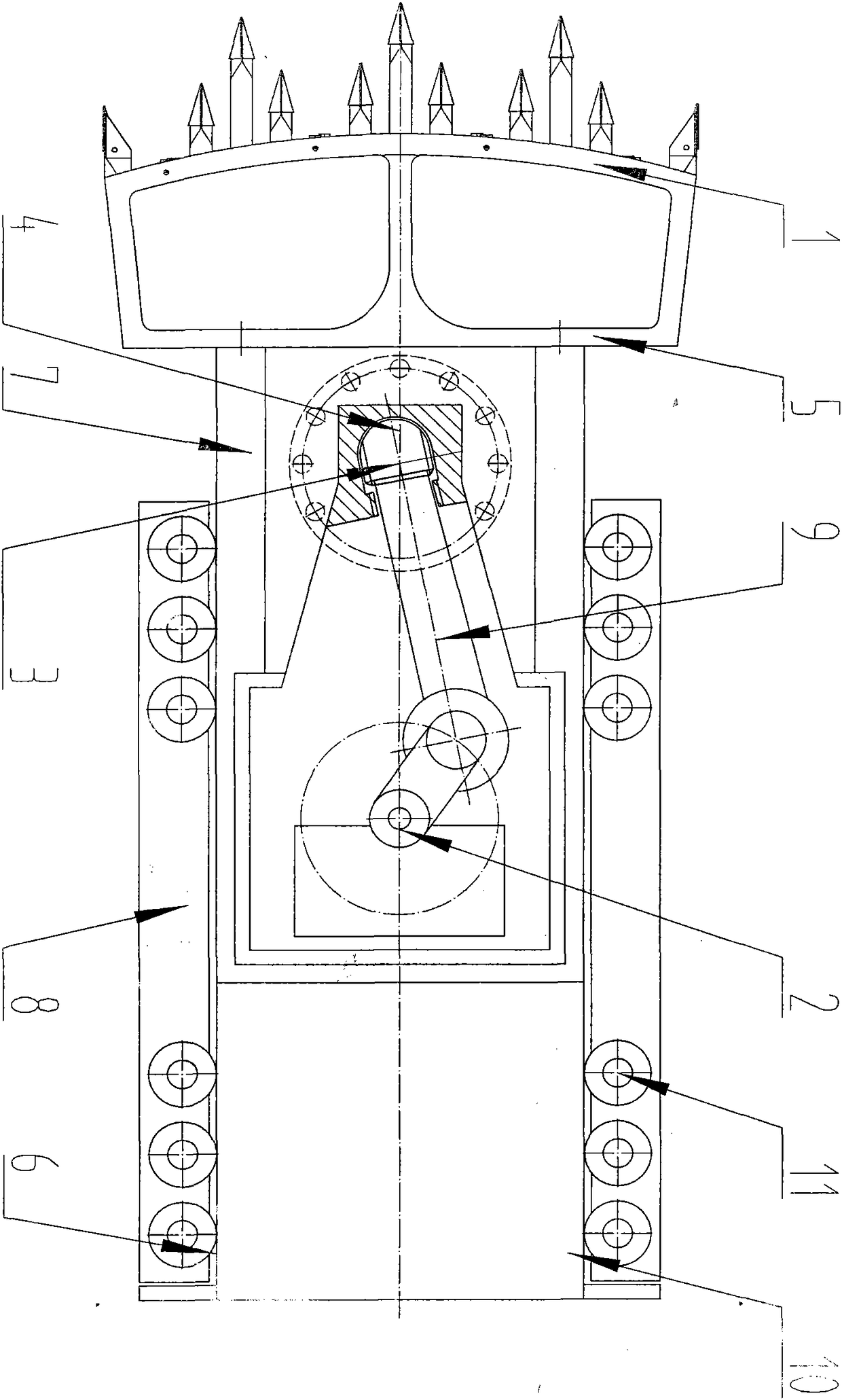

[0165] Such as figure 1As shown, the anti-damage driving component device includes a mining mechanism 1, a driving mechanism 2, and an anti-damage mining driving component mechanism 3. The damage-proof mining driving component mechanism 3 includes an anti-breaking structure 4, and the mining mechanism 1 includes an impact head 5. The device also includes a guide mechanism 6. The guide mechanism 6 includes an impact guide 7 and a guide support 8. One end of the impact guide 7 is provided with an impact head 5. The driving mechanism 2 includes a power impact member 9. The power impact member 9 and the impact guide 7 separate parts, the anti-breaking structure 4 is arranged at one end of the power impact part 9, the power impact part 9 drives the impact head 5 to reciprocate impact, and the impact reaction force is applied to the anti-breaking structure 4, and the anti-breaking structure 4 prevents the driving mechanism 2Subject to separation and / or impact damage.

[0166] In th...

Embodiment 2

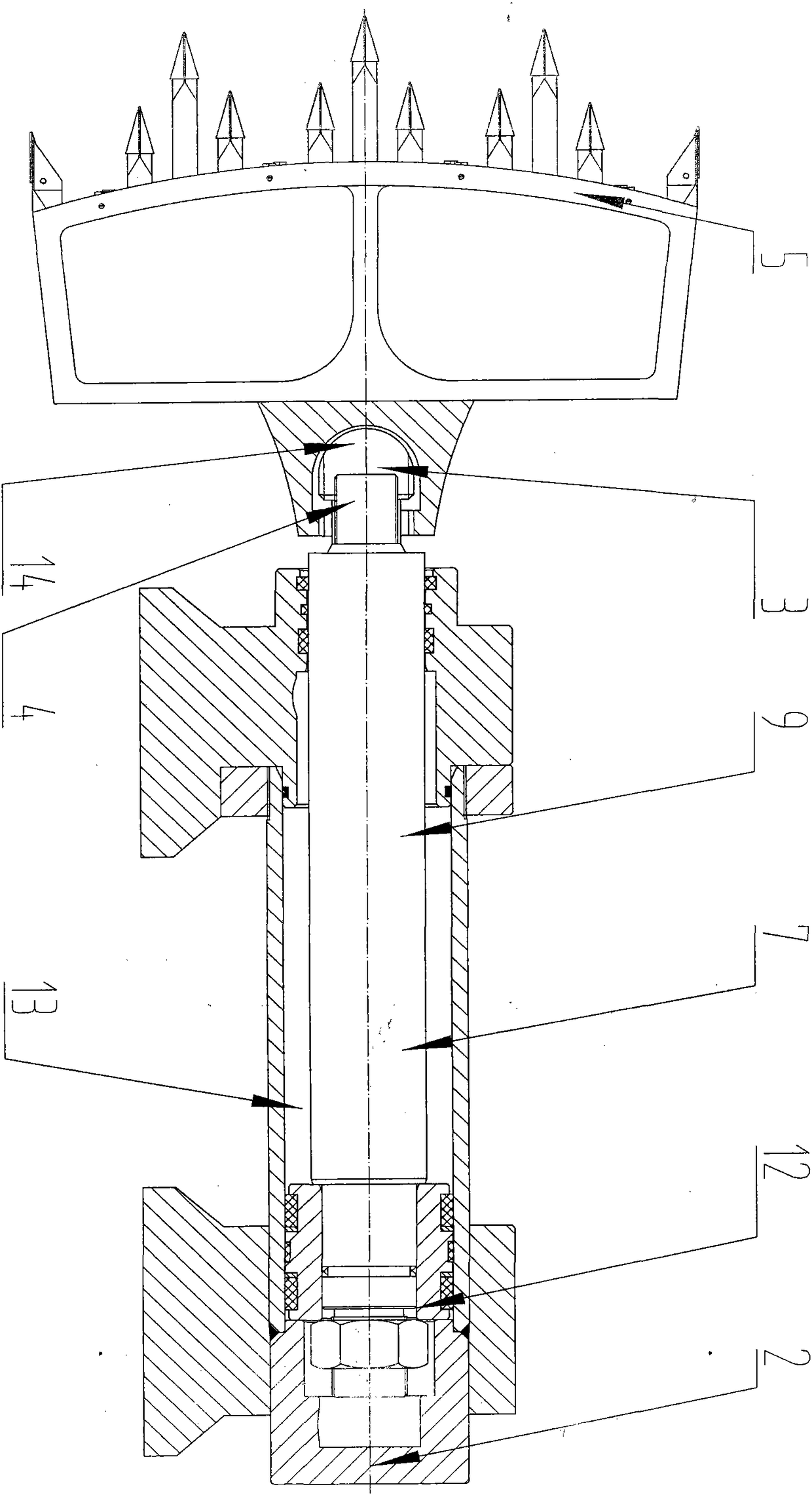

[0174] Such as figure 2 As shown in the anti-damage drive component device, the drive mechanism 2 is a hydraulic impact drive mechanism 12, the hydraulic impact drive mechanism 12 includes a cavity 13, a power impact piece 9, the power impact piece 9 and the impact guide 7 are integrated, and the power impact piece One end of 9 is arranged in the cavity 13, and an anti-damage excavation drive component mechanism 3 is arranged between the other end and the impact head 5. The anti-damage excavation drive component mechanism 3 adopts an anti-break structure 4, which is a rotation-proof structure 4. Break off the structure 14, and rotate the anti-break off structure 14 to rotate under force to protect the connecting rod 29 from being damaged by breaking off.

[0175] The drive mechanism 2 may also adopt a pneumatic impact drive mechanism.

Embodiment 3

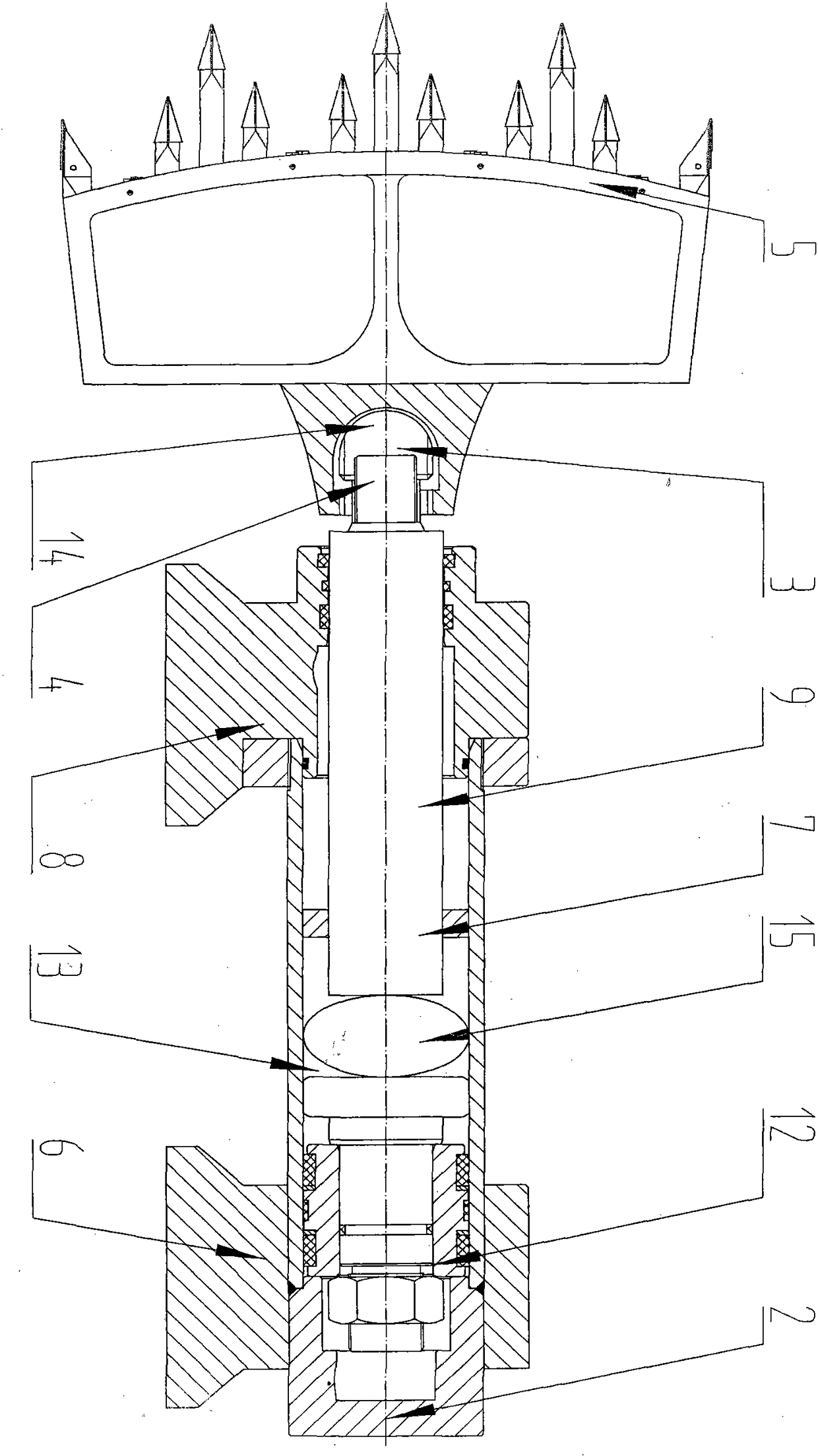

[0177] Such as image 3 As shown in the anti-damage drive component device, the guide mechanism 6 includes an impact guide 7 and a guide support 8, the drive mechanism 2 is a hydraulic impact drive mechanism 12, and the hydraulic impact drive mechanism 12 includes a cavity 13, a power impact member 9, and an air bag 15 , the power impact member 9 and the impact guide 7 are integrated, the air bag 15 is arranged in the cavity 13, one end of the power impact member 9 is arranged in the cavity 13, and an anti-damage mining drive is provided between the other end and the impact head 5. Component mechanism 3, the anti-damage excavation drive component mechanism 3 adopts the anti-break structure 4, the anti-break structure 4 is a rotation and anti-break structure 14, and the rotating anti-break structure 14 is forced to rotate to protect the connecting rod 29 from being damaged by break, The air bag 15 can further slow down the degree of separation damage.

[0178] The drive mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com