Milk bottle sterilizing machine

A technology for sterilizing machines and feeding bottles, which is applied in the fields of disinfection, cleaning methods and utensils, chemistry, etc., and can solve problems such as incomplete disinfection of feeding bottles and long disinfection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

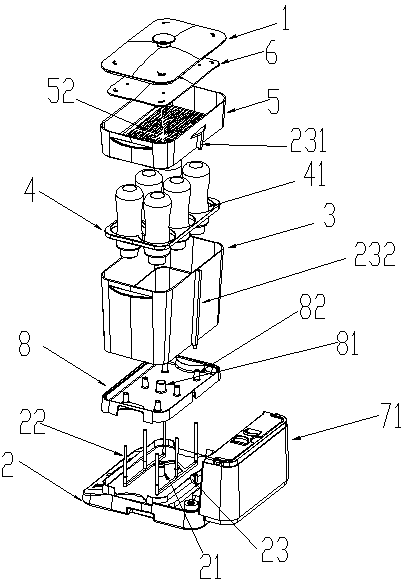

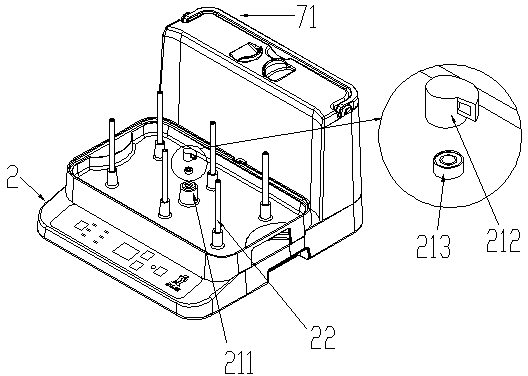

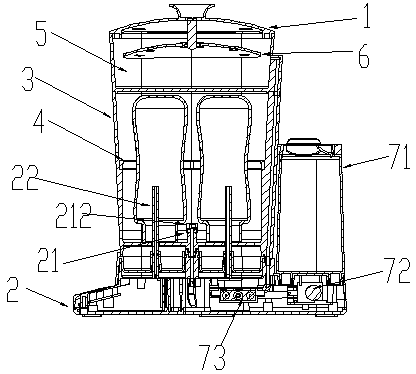

[0016] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1~4 As shown, the present invention discloses a baby bottle sterilizer, which comprises a top cover 1 and a base 2, and a placement tube 3 for holding a baby bottle to be sterilized is arranged between the top cover 1 and the base 2, and the placement tube 3 is provided with a The detachable feeding bottle fixing frame 4 has a placement hole 41 for convenient feeding bottle upside-down placement on the feeding bottle fixing frame. An upper basket 5 mainly used for holding pacifiers is arranged between the placement tube 3 and the upper cover 1. At the bottom of the upper basket There is a net 52 that allows steam to pass through for placing pacifiers, and a steam injection port 231 connected in series with the third steam injection no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com