Rotor of reversible crusher

A rotor body and crusher technology, applied in grain processing, etc., can solve problems such as shortening the service life of the hammer head, limited energy of a single hammer head, and offset of the center of gravity of the rotor, so as to improve the crushing effect, increase the service life, and reduce equipment The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

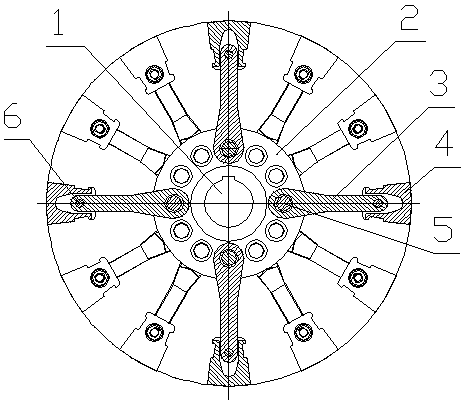

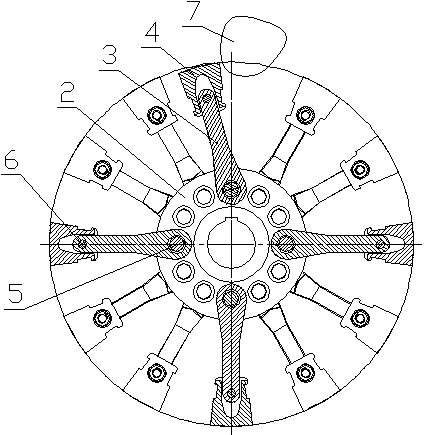

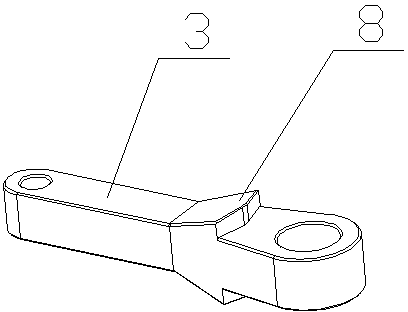

[0027] like Figure 1 to Figure 9 As shown, a rotor body of a reversible crusher includes a main shaft 11, a series of hammer discs 33 with pin holes 22, a hammer handle 44, a hammer head 55 and various connecting pins, and these connecting pins include connecting the hammer handle 44 and the hammer head The hammer head pin 88, the hammer handle pin 99 connecting the hammer disc 33 and the hammer handle 44, that is, the hammer disc 33 with the pin hole 22, the hammer handle 44, the hammer head 55 and the above-mentioned connecting pins form a unit of the rotor body, The rotor body also includes a series of follower discs 66 of units, each unit of follower discs 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap