Tricoordinate precision moving platform

A mobile platform and three-coordinate technology, which is applied in the direction of engine testing, measuring devices, instruments, etc., can solve the problems of high price, product structure movement accuracy, and cost performance that cannot meet the requirements and use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

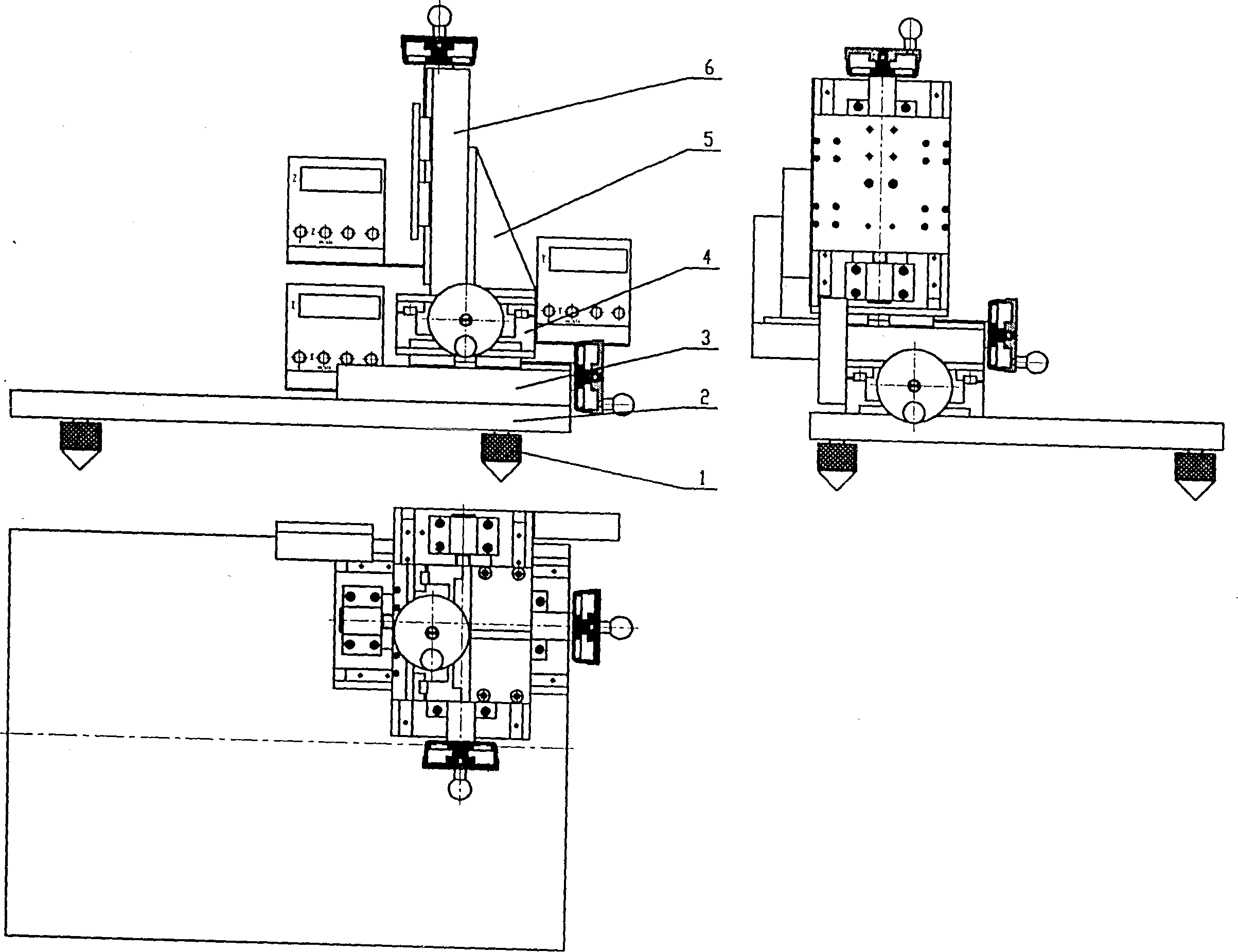

[0018] figure 1 It is the general assembly drawing of the three-coordinate precision mobile platform. The base 2 with higher flatness adjusts the level through four adjusting screws 1 . The bottom plate of the X-direction moving part 3 is fixed on the upper right corner of the mounting surface of the base 2 by a hexagon socket head cap screw. Other spaces on the mounting surface of the base 2 can place experimental devices. This design can keep the mobile platform and the experimental device at the same level. The bottom plate of the Y-direction moving part 4 is fixed on the carriage of the X-direction mobile part 3 by a hexagon socket head cap screw, and the bottom plate of the Z-direction movement part 6 is fixed by the carriage of the connecting angle iron 5 and the Y-direction movement part 4. In this way, the carriage of the Z-direction moving part 6 can move up and down (i.e. Z-direction) by the transmission of the Z direction, and the whole Z-direction movement part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com