A three-dimensional damping hinge seat for vibration reduction of parallel machine tools

A hinge seat and machine tool technology, which is applied in the field of damping and vibration reduction, can solve the problems of large motion range, inability to meet the rigidity requirements of parallel machine tools, and inability to achieve multi-dimensional vibration reduction, and achieve the effect of high motion stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

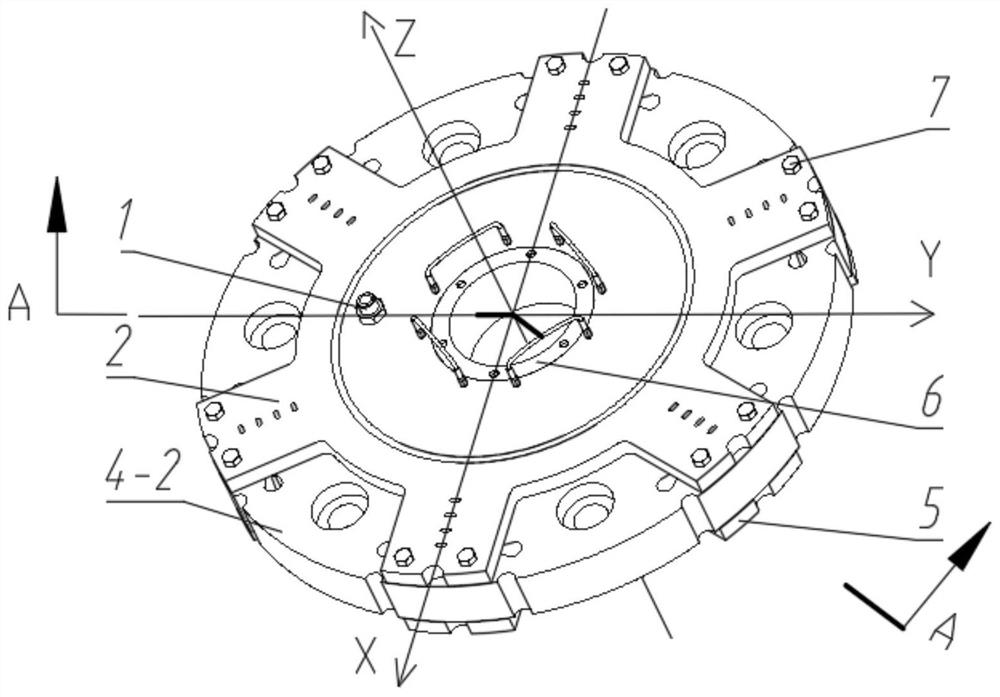

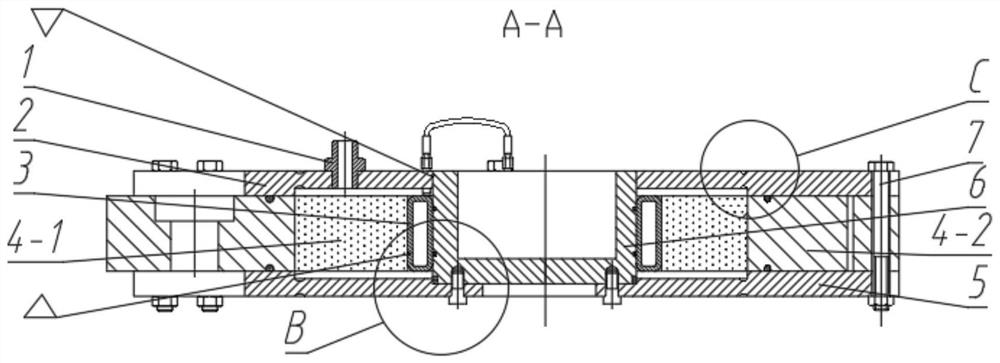

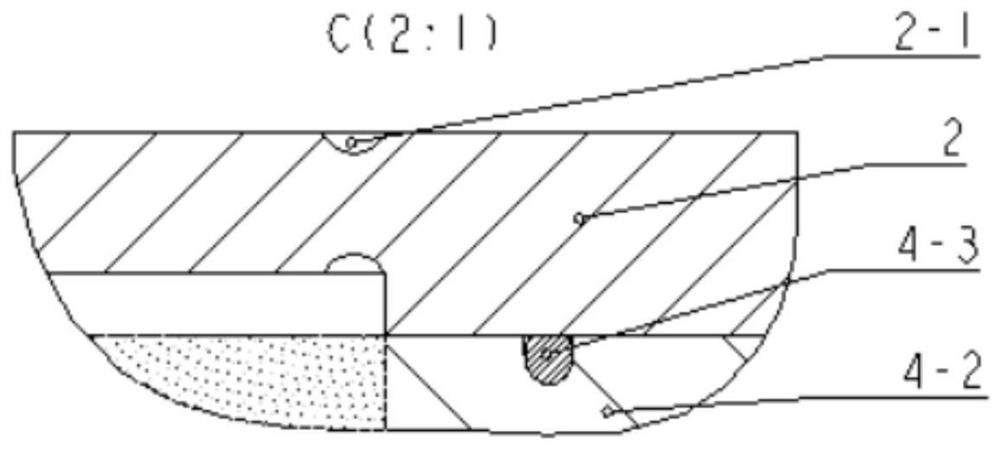

[0030] As an embodiment, the upper cylinder head 2 , the lower cylinder head 5 , and the support plate 4 - 2 are connected by bolts 7 , and the bolts connect the position of the teeth structure of the upper cylinder head 2 and the lower cylinder head 5 .

[0031] Preferably, the support plate 4-2 is provided with multiple sets of connecting holes, each set of connecting holes includes two through holes 4-5, and each through hole is provided with a bolt 7; this structure is equivalent to Figure 10 In the mechanism shown, the upper and lower cylinder heads fixedly connected with the hinge sleeve 6 form a parallelogram constraint, so that the hinge sleeve 6 can not only ensure translation but also slightly move in the direction of the Z axis.

[0032] As an implementation, the upper cylinder head 2 is provided with an oil delivery port joint 1 for filling the oil storage cavity.

[0033] In some embodiments, the upper cylinder cover 2 and the hinge sleeve 6 are fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com