Production method of soft-packaged frame-assembled door

A production method and technology for soft-packed doors, which are applied in the field of assembling processes for sliding doors and closing doors, can solve the problems of low production efficiency and many production processes, and achieve the effects of low cost, simple assembling process, and fewer production material preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be further described with reference to the drawings and specific embodiments.

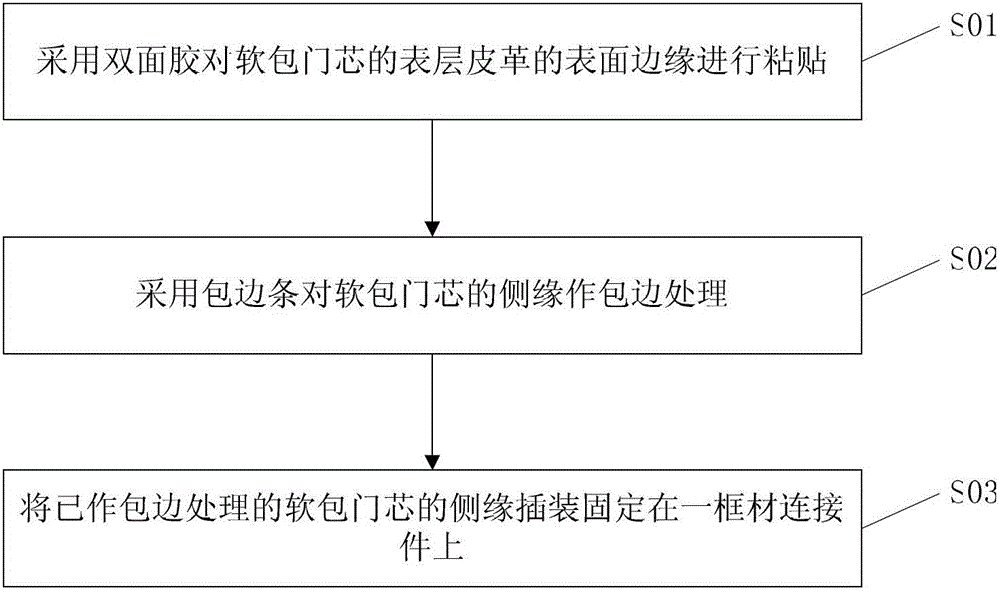

[0029] Combine Figure 1 to Figure 5 , A method for manufacturing soft-packed frame door, which includes the following steps:

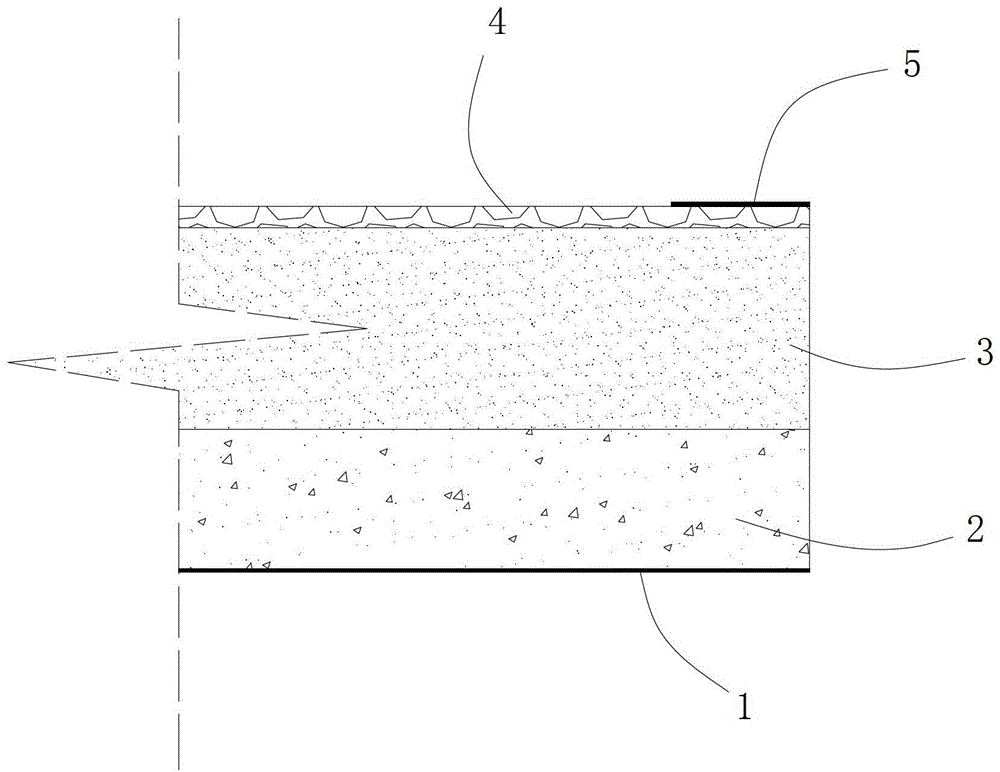

[0030] Step S01: Adhere the double-sided tape 5 to the surface edge of the surface leather 4 of the soft-covered door core. The width of the double-sided tape 5 should be 6.5 mm, so that the upper plate 61 in step S02 can cover it. The soft door core is composed of a bottom PVC film 1, a medium-density fiberboard 2, a high-density foamed cotton layer 3 and a surface leather 4 which are sequentially stacked from bottom to top.

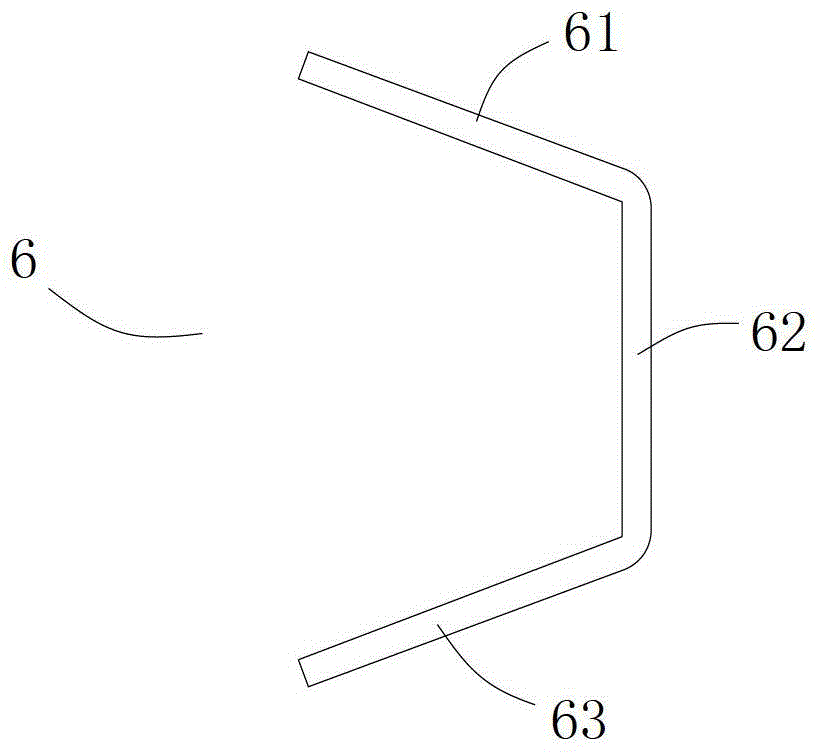

[0031] Step S02, using the edging strip 6 to encapsulate the side edge of the soft-clad door core. The edging strip 6 includes an upper plate 61, a connecting plate 62 and a lower plate 63. One side edge of the upper plate 61 is flexibly connected to one side edge of the connecting plate 62, and the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com