Cable quick connector

A cable and fast technology, which is applied in the direction of cable joints, circuits, connections, etc., can solve the problems of imprecise binding and connection, easy to be exposed to water, etc., achieve the effects of low cost, prolong life, and improve equipment operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

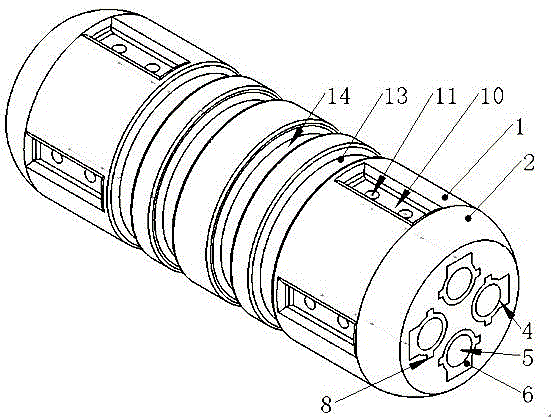

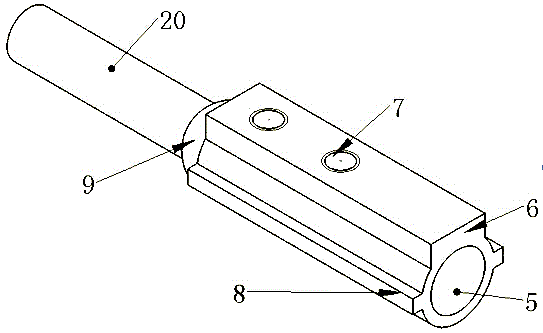

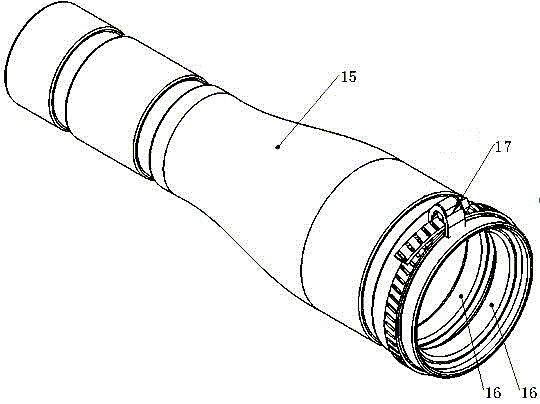

[0029] exist figure 1 In the middle, it is convenient to install on the front end face 2 of the insulating rod 1 and process it into an end face with a certain arc. Both ends of the insulating rod 1 are respectively built with mutually symmetrical cable sockets 4. In order to prevent the cable 18 from being disconnected from the cable socket 4 during the dragging process, a pattern 5 is provided on the inner cavity wall of the cable socket 4 to achieve The purpose of increasing the friction force; one end surface of the cable socket 4 is flush with the end surface of the insulating rod 1, and the other end surface is connected by a connecting cable 20. The cable socket 4 is a hollow metal rod, and the outer wall surface of the cable socket 4 is provided with reinforcement Wall 6, reinforced ribs 8 are respectively provided on both sides of the reinforced wall 6 to ensure that the cable 18 cannot rotate in the cable socket 4, and at the same time, a reinforcing boss is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com