Lock having a modified spring lip for motor vehicle doors

A motor vehicle, flexible technology, applied in the direction of vehicle locks, building locks, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

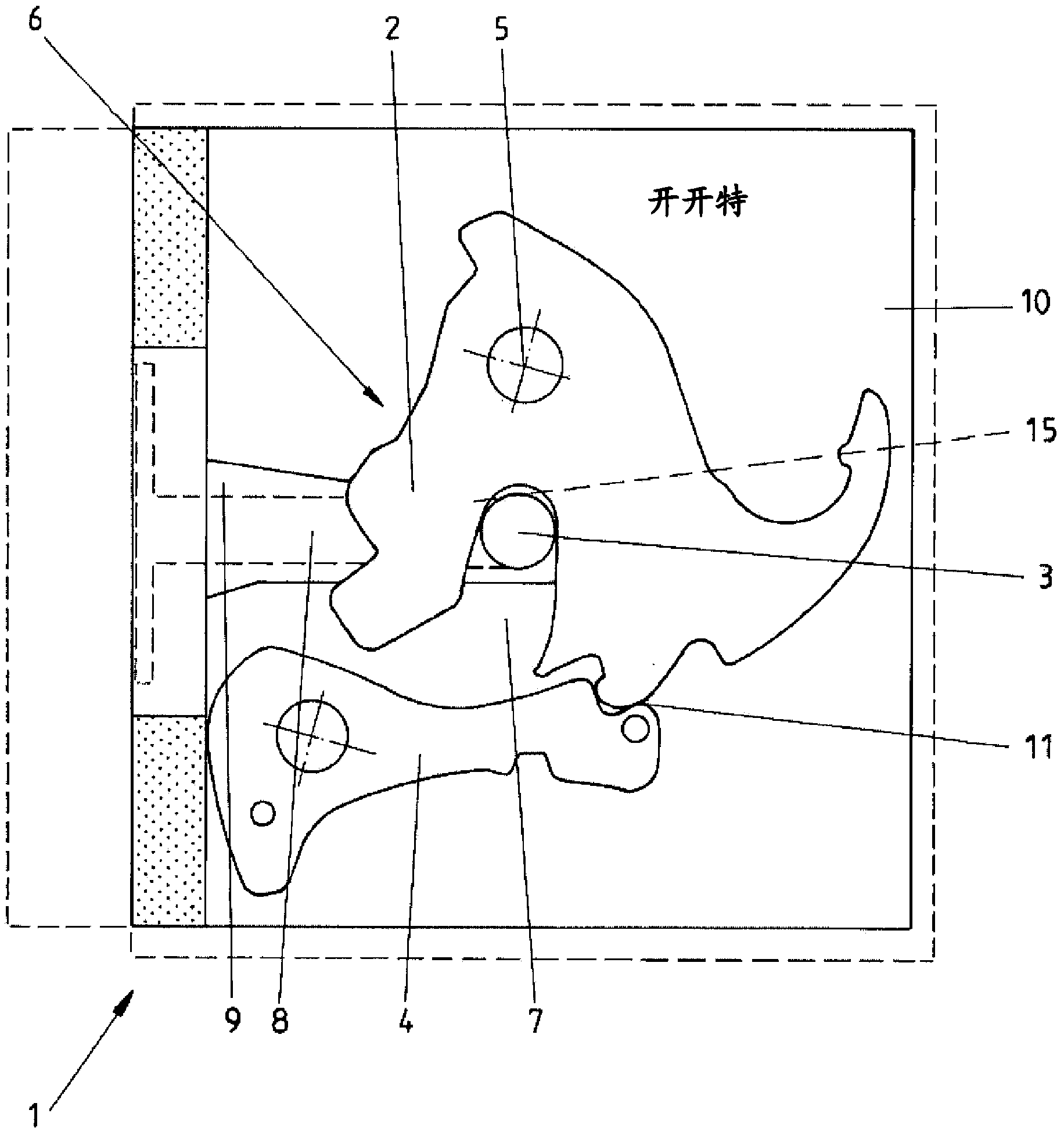

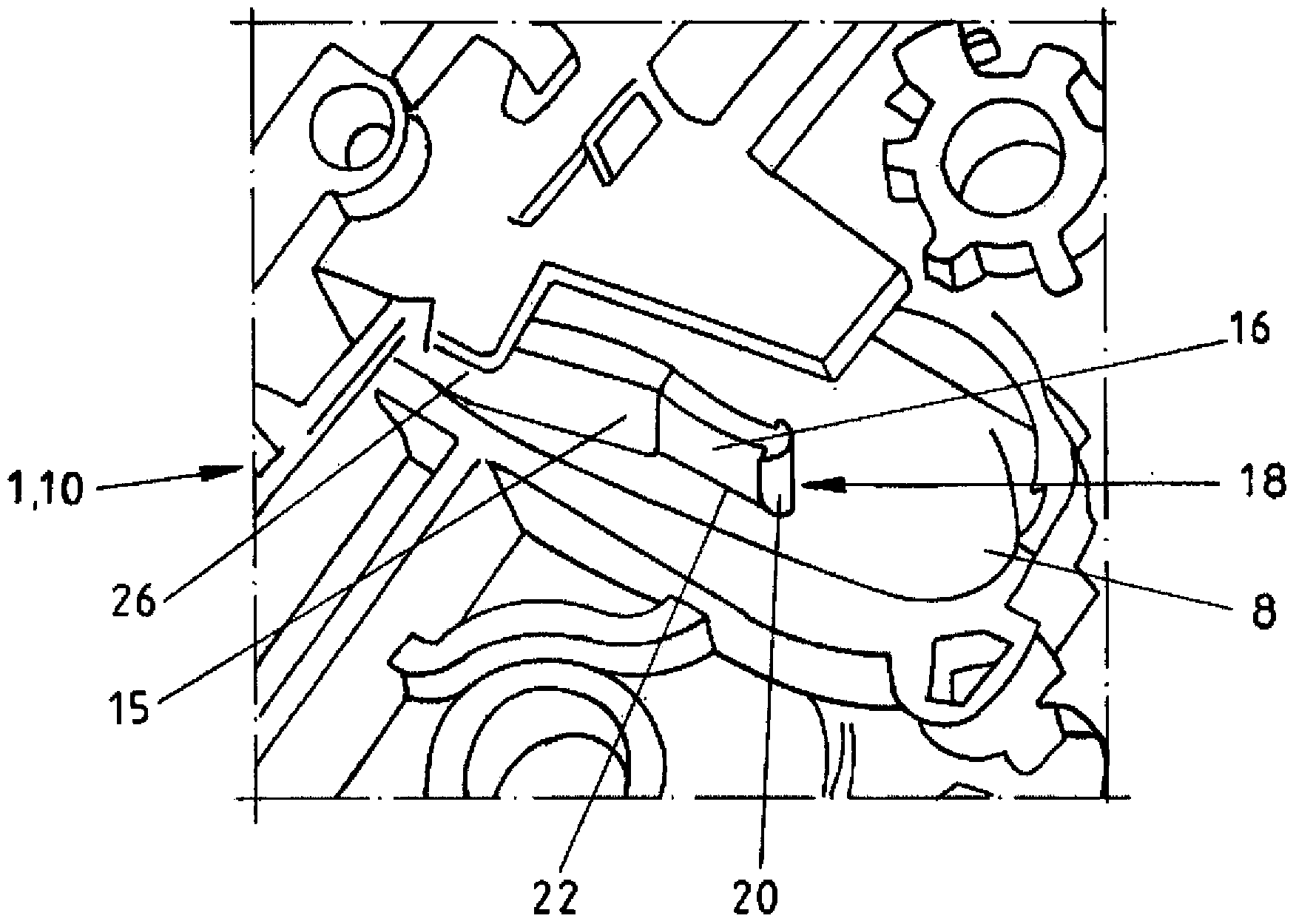

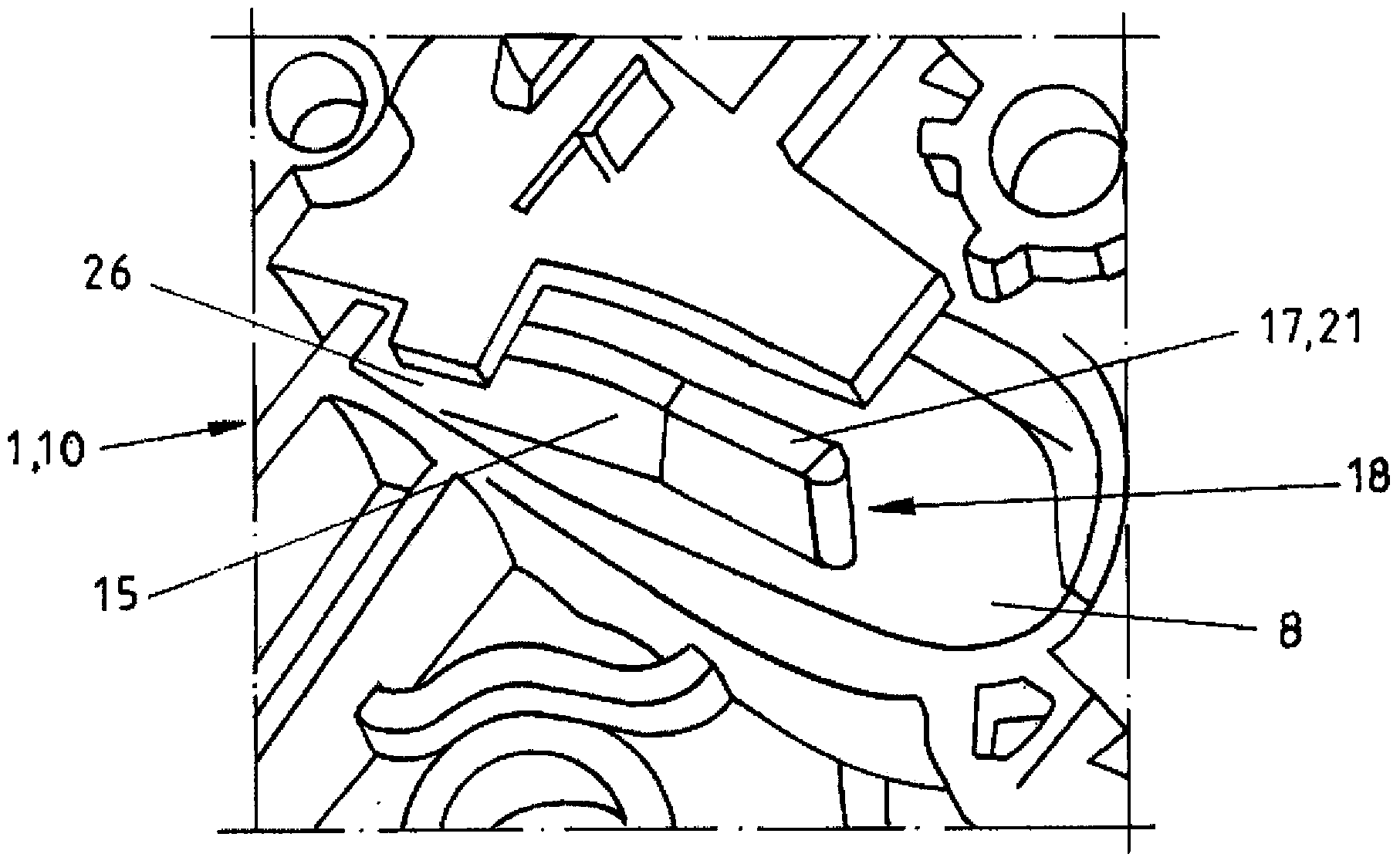

[0025] figure 1 Shown is a lock 1 , here a motor vehicle door lock, which has a locking mechanism 6 consisting of a rotary latch 2 and a pawl 4 . In the closed position shown, the rotary latch 2 with the opening 7 surrounds the locking bolt 3 , wherein the rotary latch 2 is pivotable about the pivot axis 5 . To fix this position, the pawl 4 is swiveled such that its projection 11 abuts against the rotary latch 2 and forms a targeted and precisely defined contact area in the region of the notch, by which the rotary latch is blocked. The lock part swings back 2 times. All these lock parts are arranged in a lock housing 10 which has a guide link 8 for the lock bolt 3 , the input side of which is referenced 9 .

[0026] The rotary latch 2 generally has a casing made of plastic, wherein the contact area of the rotary latch 2 with the locking bolt 3 is generally not provided with a casing, so that metal-to-metal contact occurs here when the pawl 4 falls in. The pawl 4 can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com