Electric cutting device for rapidly cutting animal corneas

A technology for cutting devices and corneas, which is applied in the fields of animal restraint equipment, medical science, veterinary equipment, etc., and can solve problems such as impact, difficulty in scientific standardization, and hindrance to the in-depth development of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

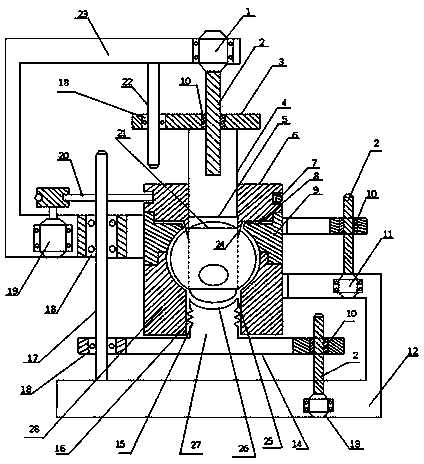

[0016] When using, first prepare a large batch of fresh isolated animal eyeballs for experiments, and select an electric fast animal eye cornea cutting device of the corresponding size according to the type of animal used, and carry out disinfection and disassembly and combination work in advance, first upward Start the bracket motor 13, first push the movable suction bracket 14 into the round hole of the sliding chamber 16 at the bottom of the front eyeball fixing box 28, let the displaceable sealing ring 15 stick to the sliding chamber 16 and seal it well, and start to lift upwards The motor 11 separates the rear eyeball fixing box 9 from the upper part of the anterior eye fixing box 28, and puts the selected isolated animal eye downward into the circular groove of the anterior eyeball fixing box 28, so that the cornea just sticks to the cornea contact grid 26, And guarantee that the fixed cutter barrel on the cornea contact grid 26 is just aligned with the cornea cutting lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com