Guiding locating structure

A technology of guiding positioning and positioning grooves, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of complex positioning process, poor positioning accuracy, and non-quantitative translation, and achieve the effect of simple positioning and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

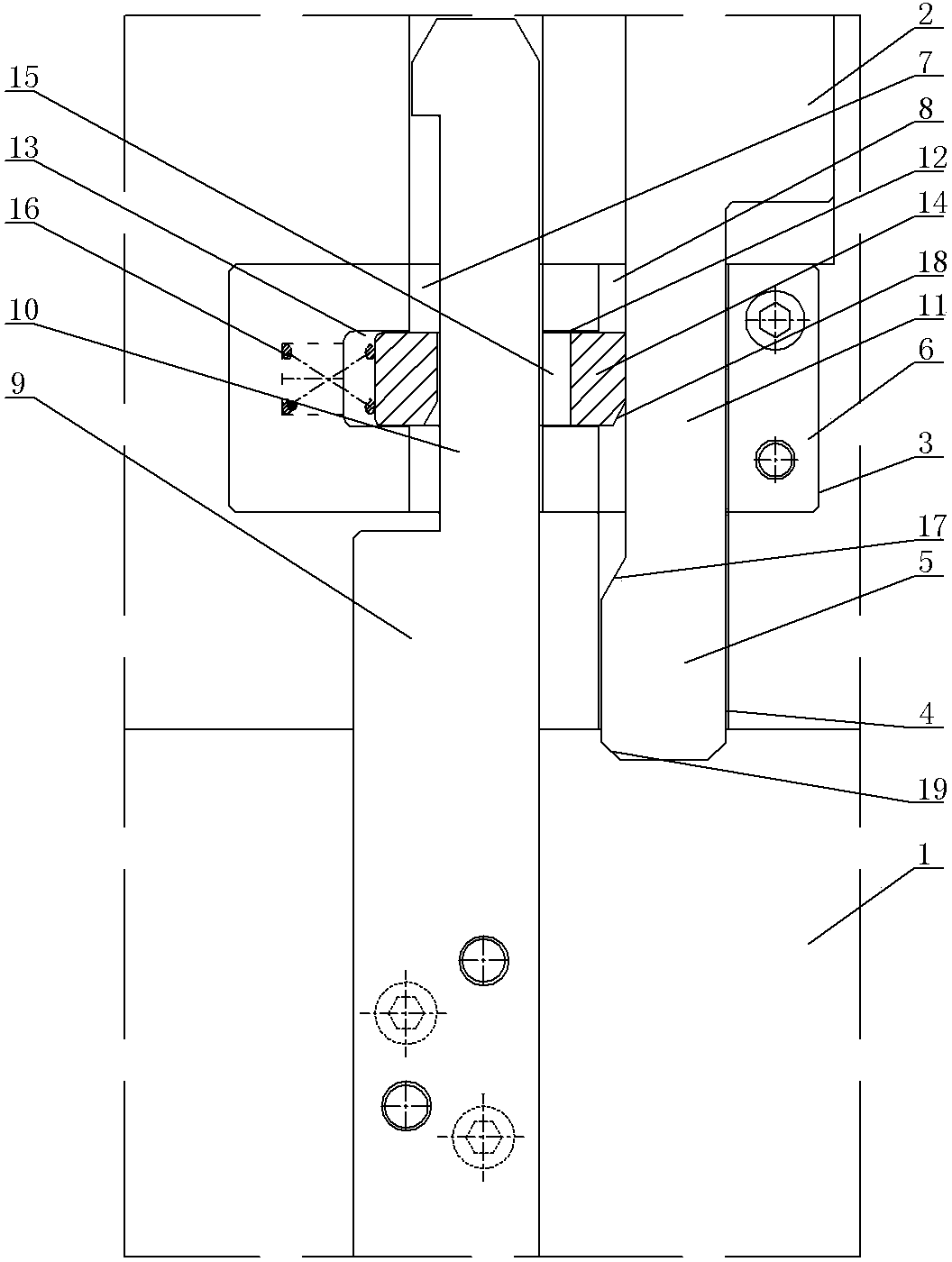

[0007] See figure 1 , which includes a fixed base plate 1, a moving block 2, a cavity 3 and a moving block positioning groove 4 are opened in the middle of the fixed base plate 1, the end part 5 of the moving block 2 is placed in the moving block positioning groove 4, and a guide is installed in the cavity 3 Block 6, the guide block 6 is provided with two parallel guide cavities 7, 8, the upper guide end 10 of the guide column 9 is installed in the guide cavity 7 on one side, and the lower positioning end of the guide column 9 is fastened to the fixed base plate 1, The lower guide part 11 of the moving block 2 is housed in the guide cavity 8 on the other side, and the middle positions of the two guide cavities 7 and 8 are provided with a communicating limiting groove 12, which corresponds to the position of the guiding cavity 7 on one side. The side wall has a corresponding positioning groove 13, and the positioning block 14 is sleeved on the upper guide end 10 of the guide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com