Labor-saving stapler

A technology of a stapler and a knife holder, applied in the field of machinery, can solve the problems of poor labor-saving effect and no change, and achieve the effects of simple structure, high practical value, and obvious labor-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

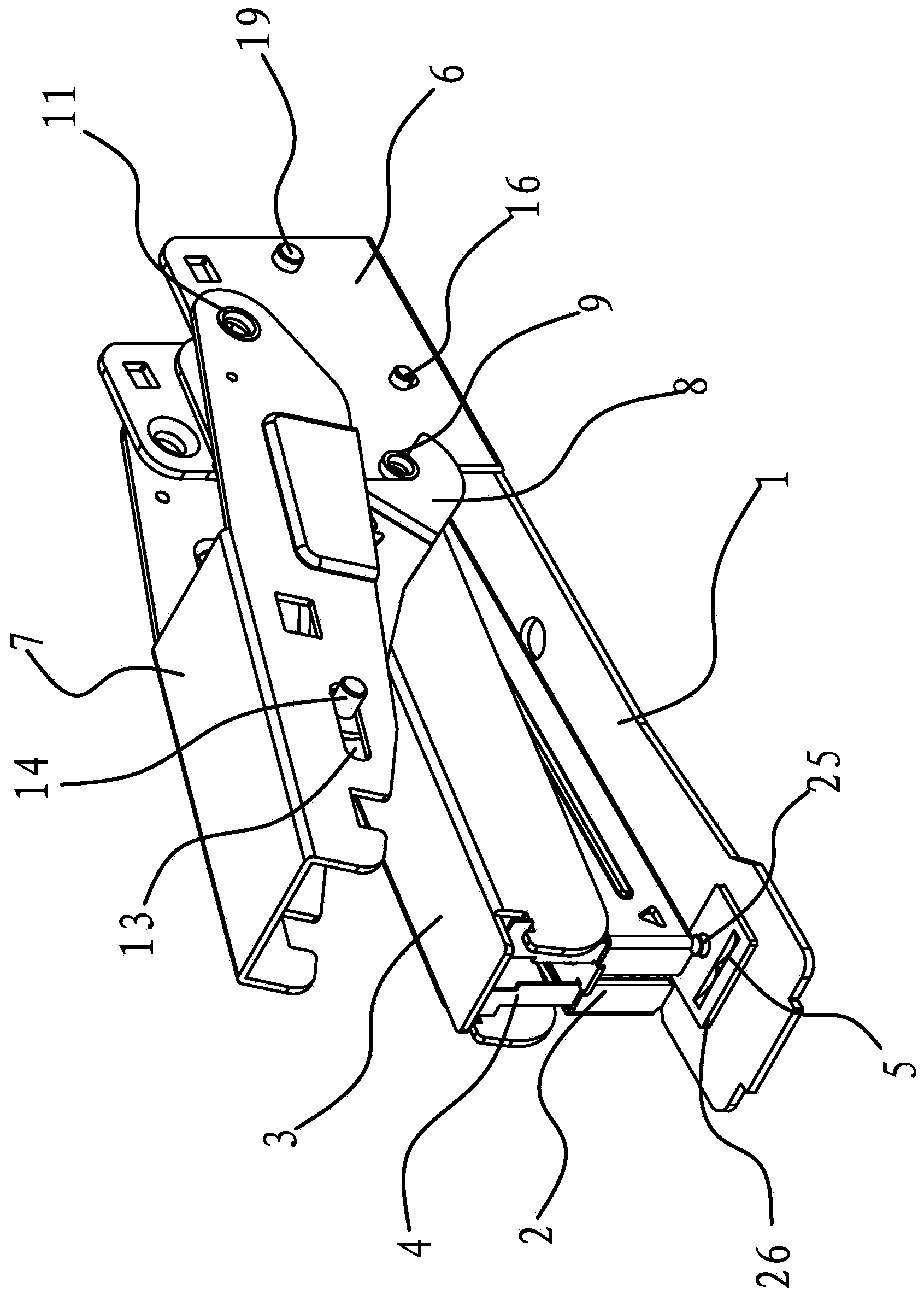

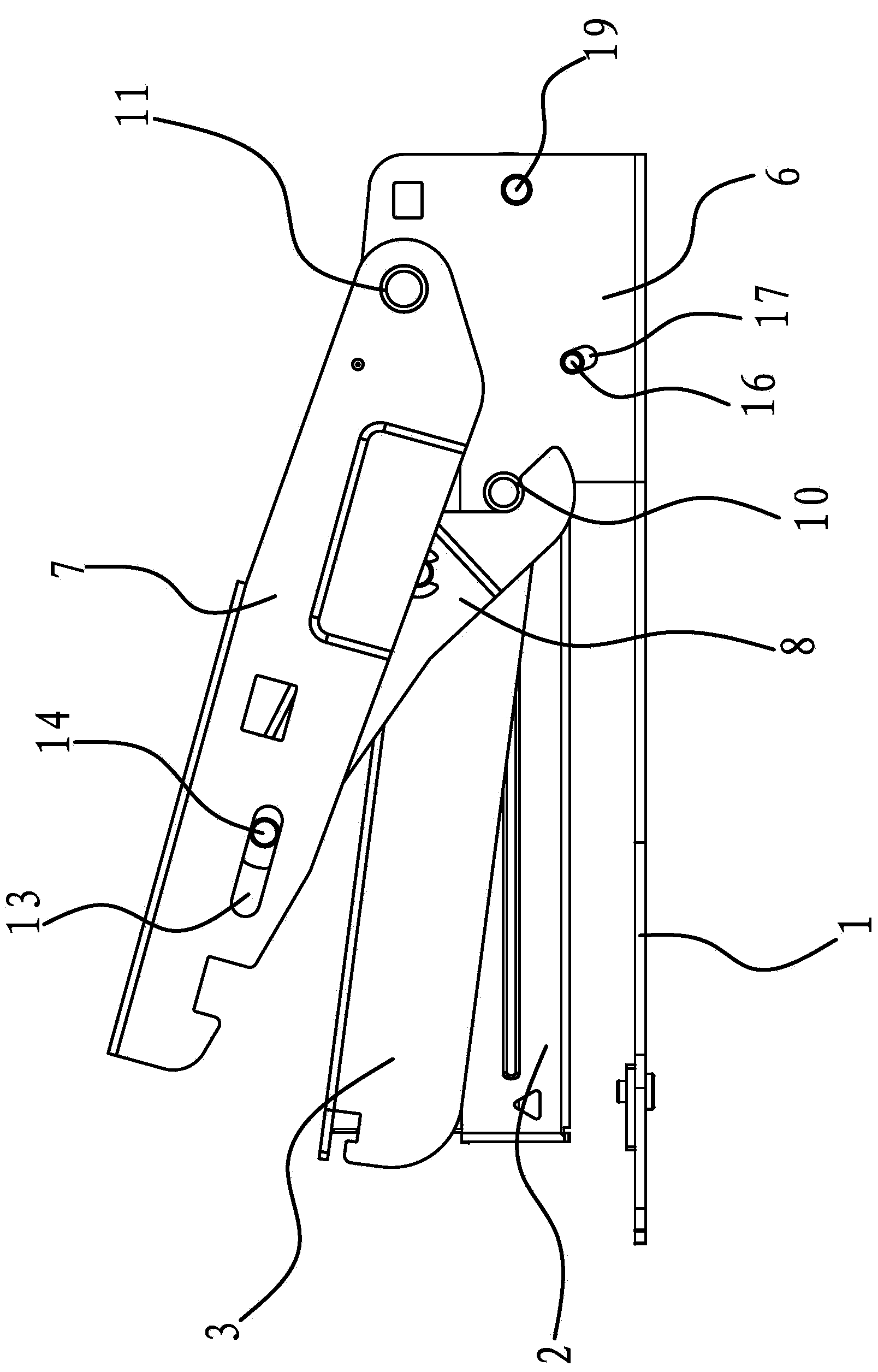

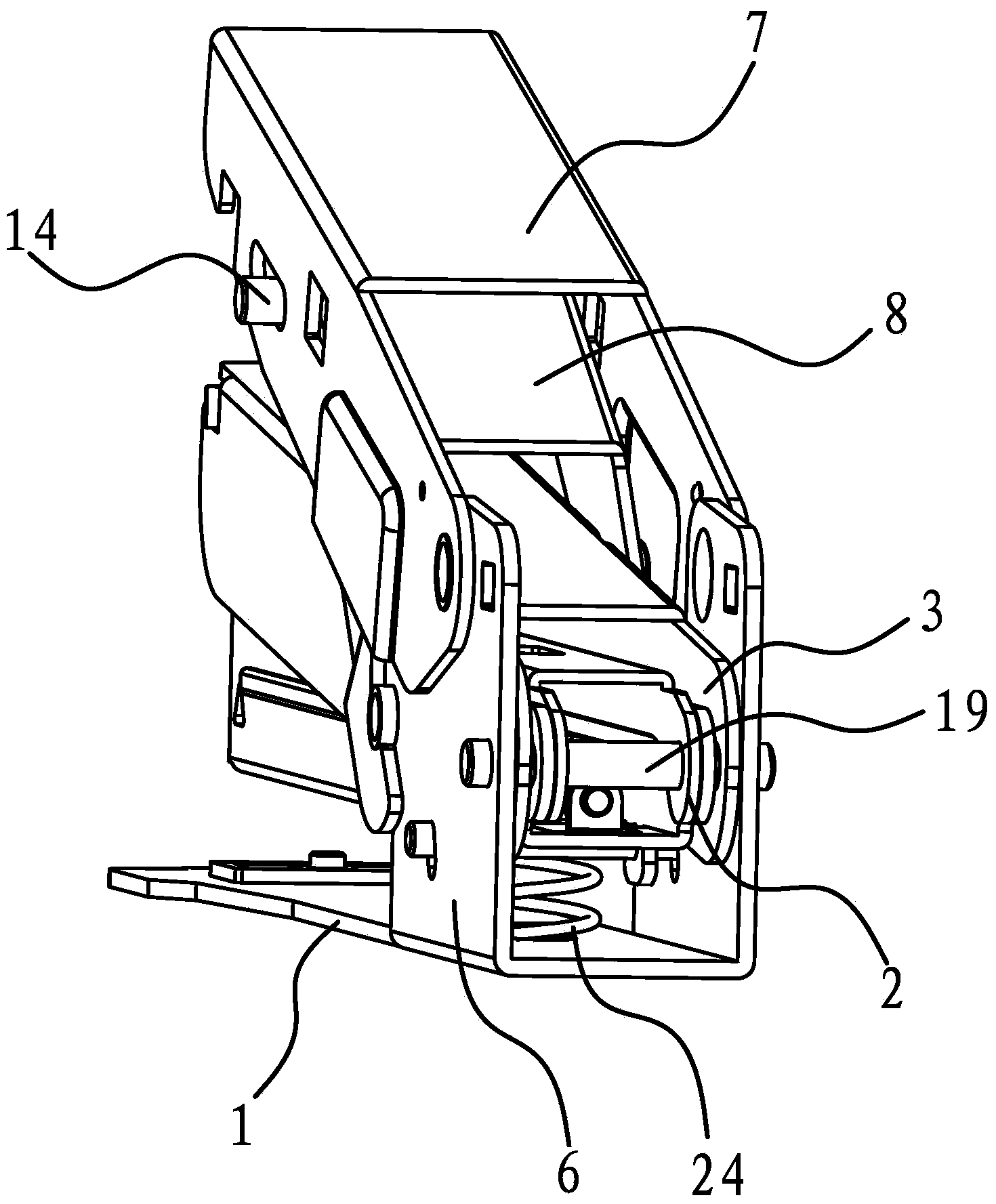

[0031] Such as Figure 1-Figure 4 As shown, a labor-saving stapler comprises a base 1, a nail path 2 and a knife rest 3, the outer end of the knife rest 3 is provided with a blade 4, and the outer end of the base 1 is fixedly connected with a connecting plate 26 by a screw 25, and on the connecting plate 26 Be provided with knife edge 5. The inner end of the base 1 has a positioning bracket 6, the two sides of the positioning bracket 6 have connecting holes 18 and a connecting shaft 19 is arranged between the two connecting holes 18, and the connecting shaft 19 passes through the inner end of the tool holder 3 and the inner end of the nail path 2 respectively. . In this embodiment, a return spring 24 is provided between the base 1 and the bottom of the nail track 2 , and the nail track 2 tends to move upward under the elastic force of the return spring 24 . There are protruding connecting parts 15 on both sides of the bottom of the inner end of the nail channel 2, and a limi...

Embodiment 2

[0041] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that both sides of the outer end of the connecting frame 8 in this embodiment have guide grooves 13, and the two guide grooves 13 are oppositely arranged, and the iron cover 7 A guide pin 14 is transversely pierced between the two sides of the connecting frame 8 and the guide pin 14 passes through the guide grooves 13 on both sides of the outer end of the connecting frame 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com