Compensated drainage floor drain

A compensating, floor drain technology, which is applied in water supply installations, indoor sanitary plumbing installations, buildings, etc., can solve the problems of increased floor drain installation height, slow floor drain drainage speed, and increased difficulty in floor drain installation, achieving increased and reduced drainage speeds The effect of reducing the depth and installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

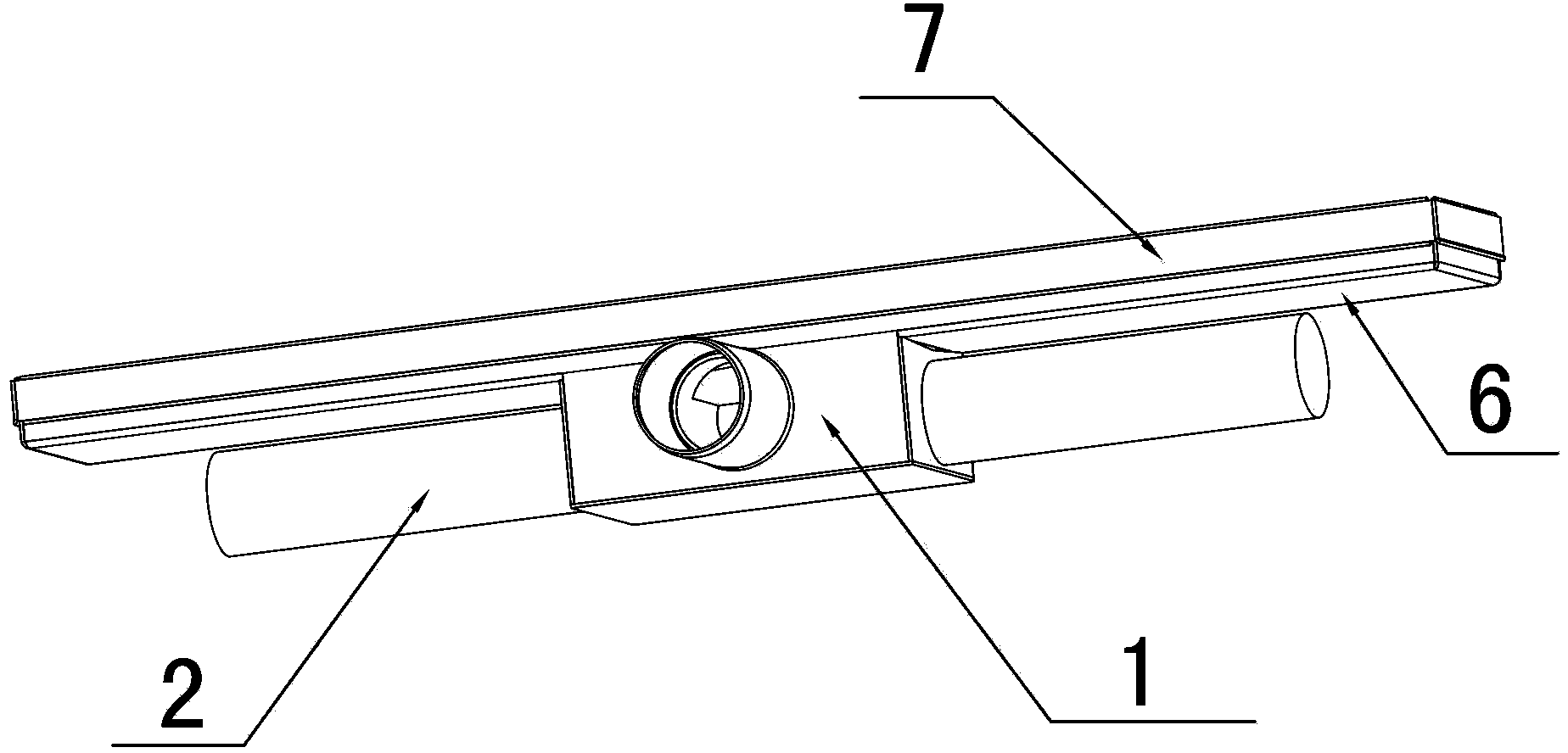

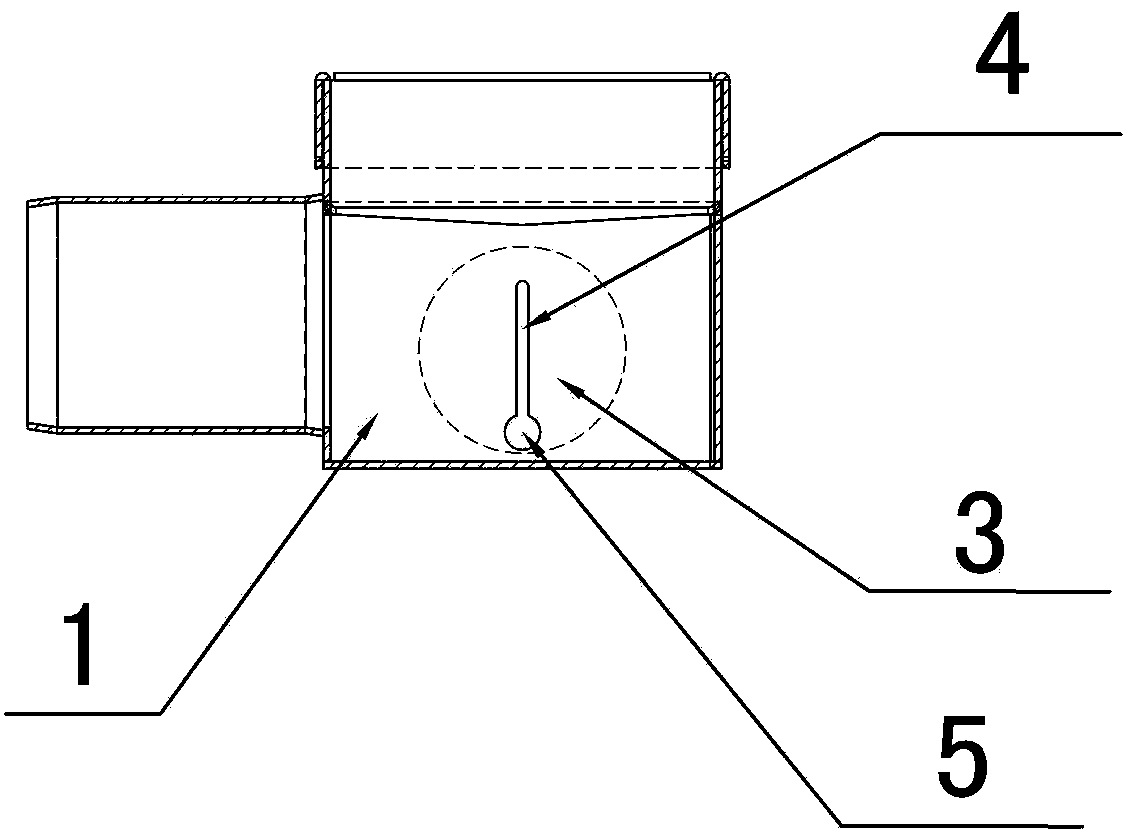

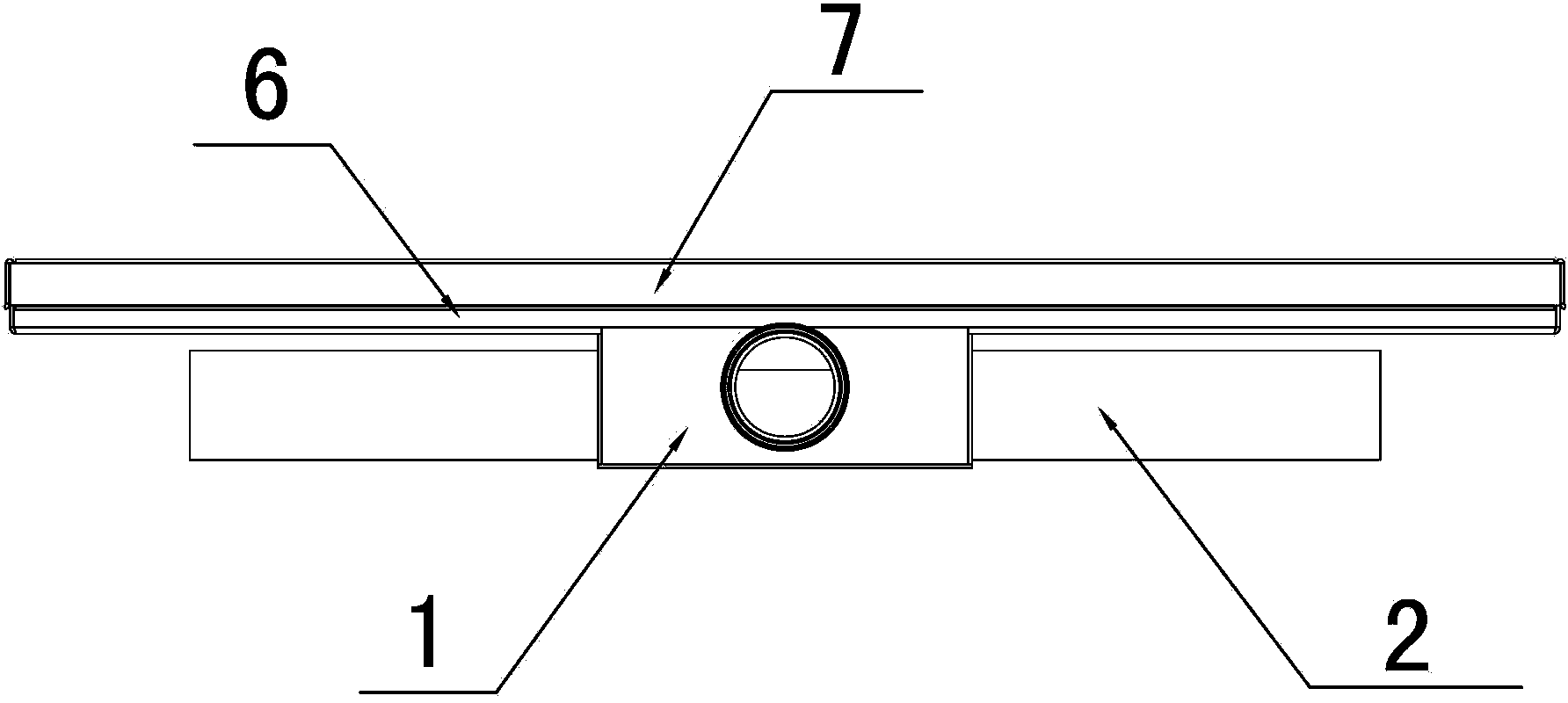

[0020] Embodiment: As shown in the figure, a compensated drainage floor drain includes a water tank 1 and an outlet pipe 2. The water tank 1 has a front side 3 and two side surfaces 4. The water outlet pipe 2 is arranged on the front side 3. A water diversion tank 5 is extended, and at least one water storage pipe 6 for replenishing water to the water tank 1 is provided. The water storage pipe 6 is arranged on the two sides 4 and communicates with the water tank 1 through a narrow water replenishment seam 7. The water storage pipe 6 is far away from the One end of the water tank 1 is a closed end 7, and the water storage pipe 6 is located directly below the water diversion tank 5, and the closed end 8 does not extend beyond the end of the water diversion tank 5. When the water evaporation in the water tank 1 decreases, the water in the water storage pipe 6 Water is just replenished in the middle of the tank 1 by the water filling seam 7 .

[0021] In this embodiment, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com