Star wheel drive mechanism for conveying bottles

A transmission mechanism, star wheel technology, applied in conveyors, rotary conveyors, transportation and packaging, etc., can solve problems such as affecting production efficiency, inconvenient operation, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

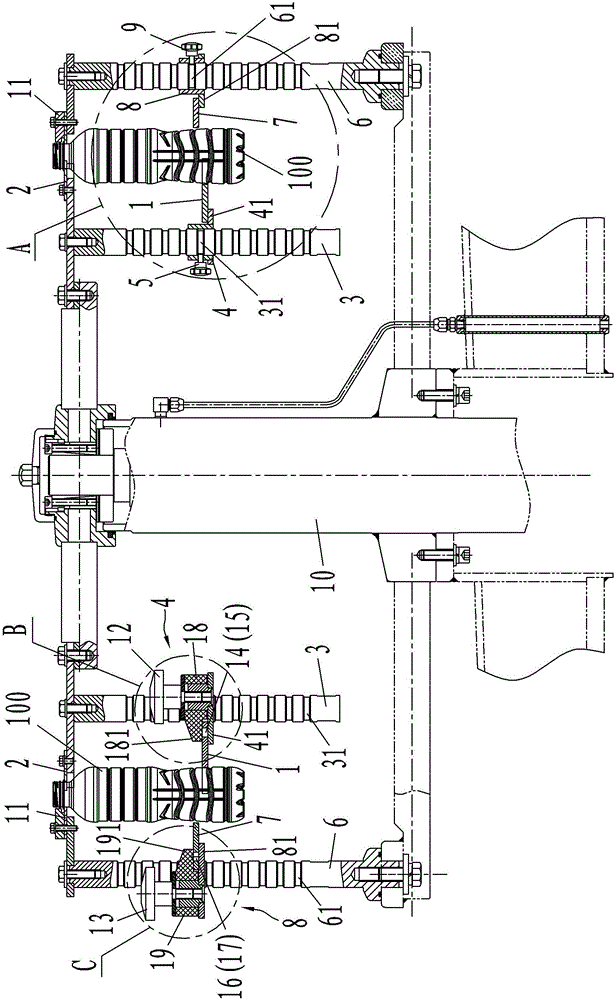

[0012] For ease of understanding, figure 2 Part A does not show components such as pressing block 18, screw rod 12 with handle, latch 14, socket 15, pressing piece 19, screw rod 13 with handle, latch 16 and socket 17; part B does not show the first Parts such as the screw rod 5 are shown; part C does not show the second screw rod 9 and other parts.

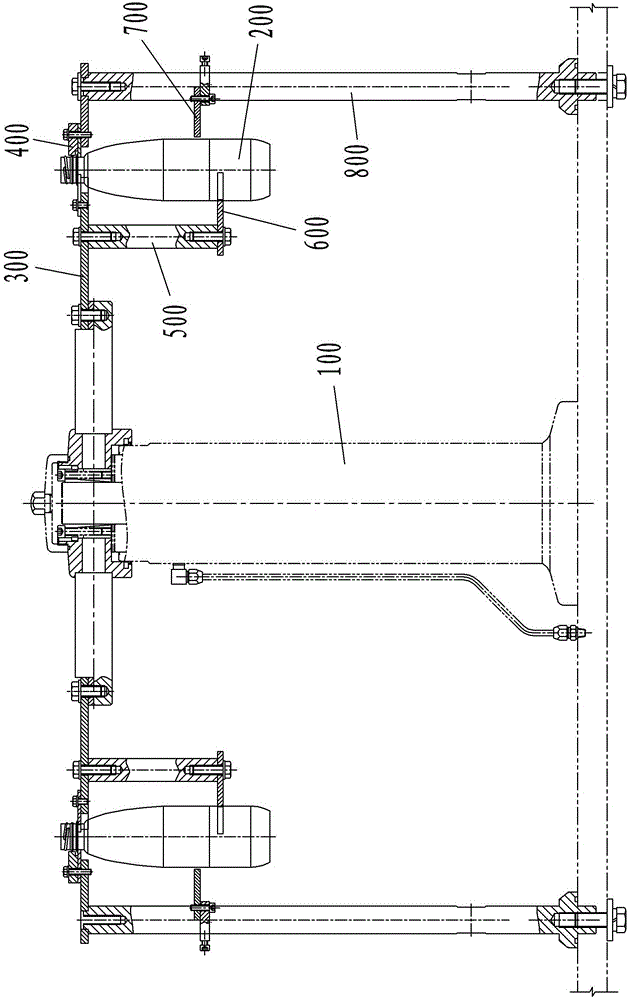

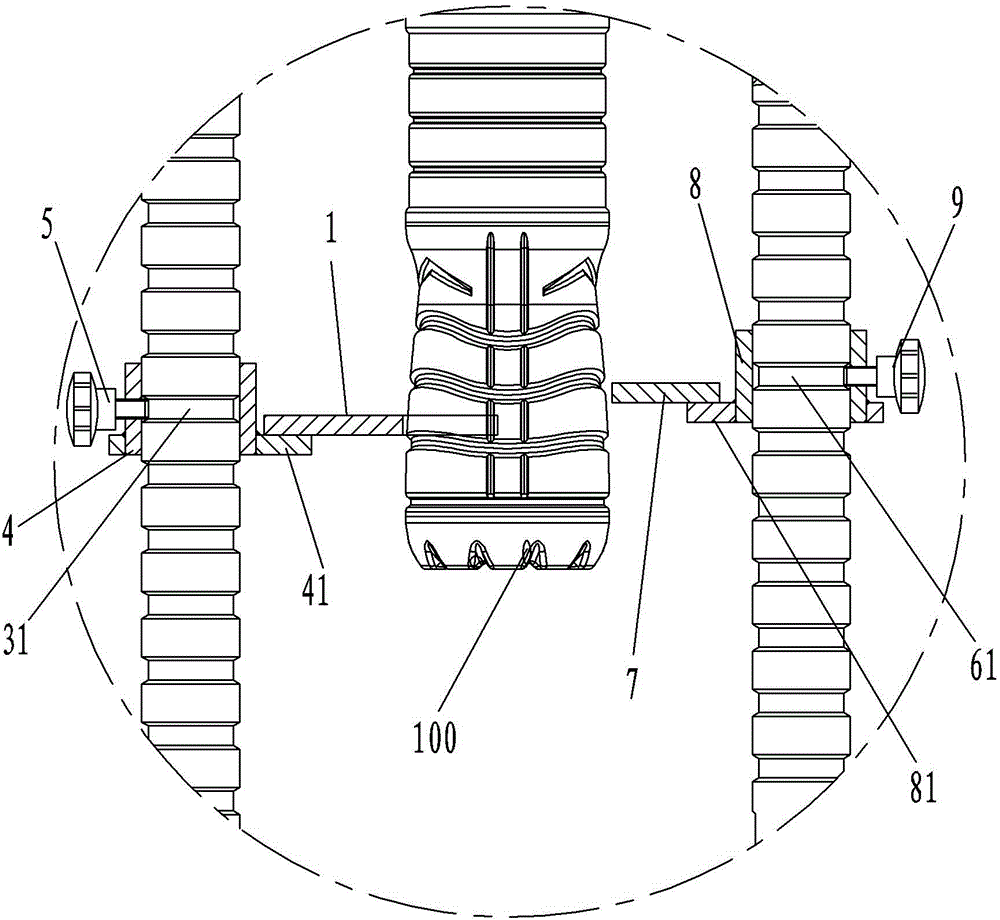

[0013] Such as Figures 2 to 7 As shown, the star wheel transmission mechanism for conveying bottles includes a lower star wheel 1, a pillar 3 fastened to the upper star wheel 2, and a lower bottle-shaped plate 7 fastened to the column 6, the pillar The length of 3 can ensure that the height adjustment requirements of various bottles 100 are met. The upper star wheel 2 is installed on the rotating shaft 10 and can rotate with the rotating shaft 10, and cooperates with the upper bottle-shaped plate 11 fixed on the column 6. The above-mentioned pillar 3 is covered with a mounting seat 4 that can move up and down along the pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com