Fastening type pneumatic punching machine capable of automatically adjusting height

An automatic adjustment, pneumatic punching technology, applied in the direction of perforation tools, safety equipment, manufacturing tools, etc., can solve the problems of inaccurate punching position, labor consumption, stepping on the foot switch, etc., to facilitate automatic adjustment and extended use. Longevity, the effect of reducing the time-consuming adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

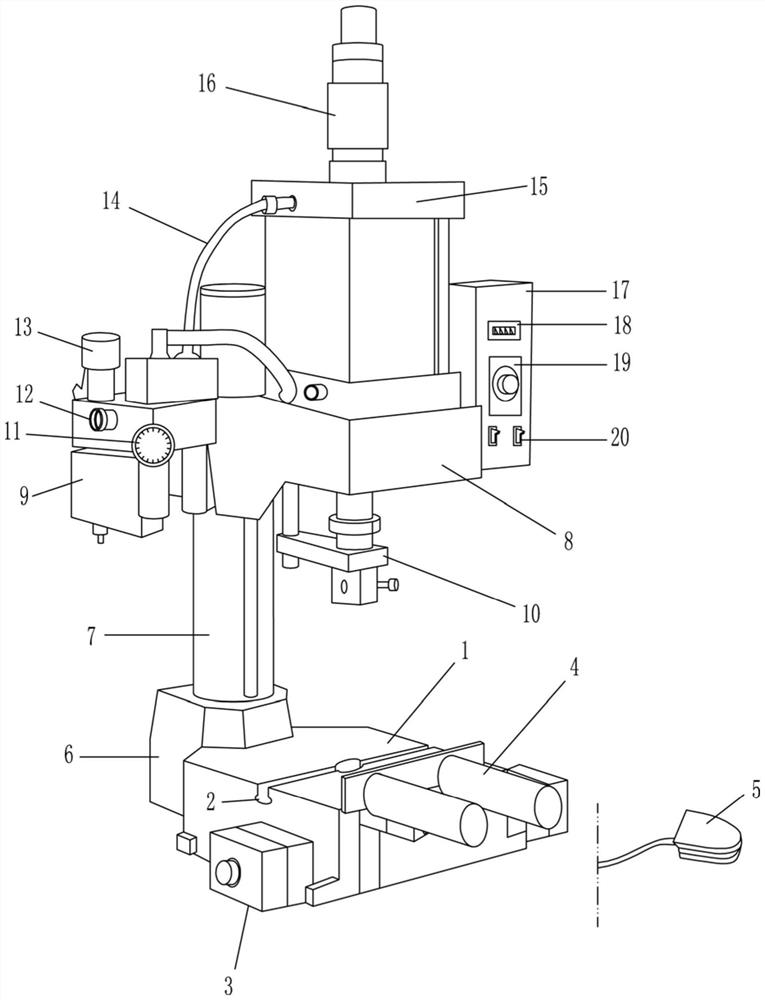

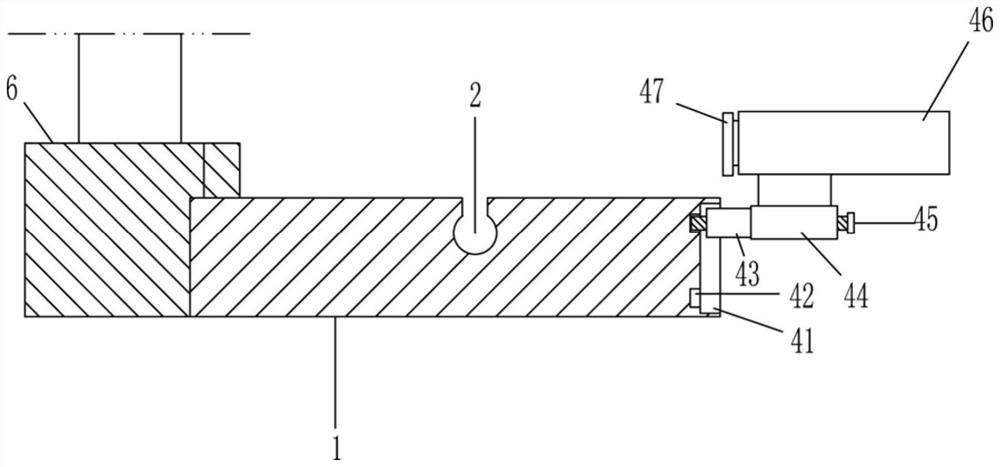

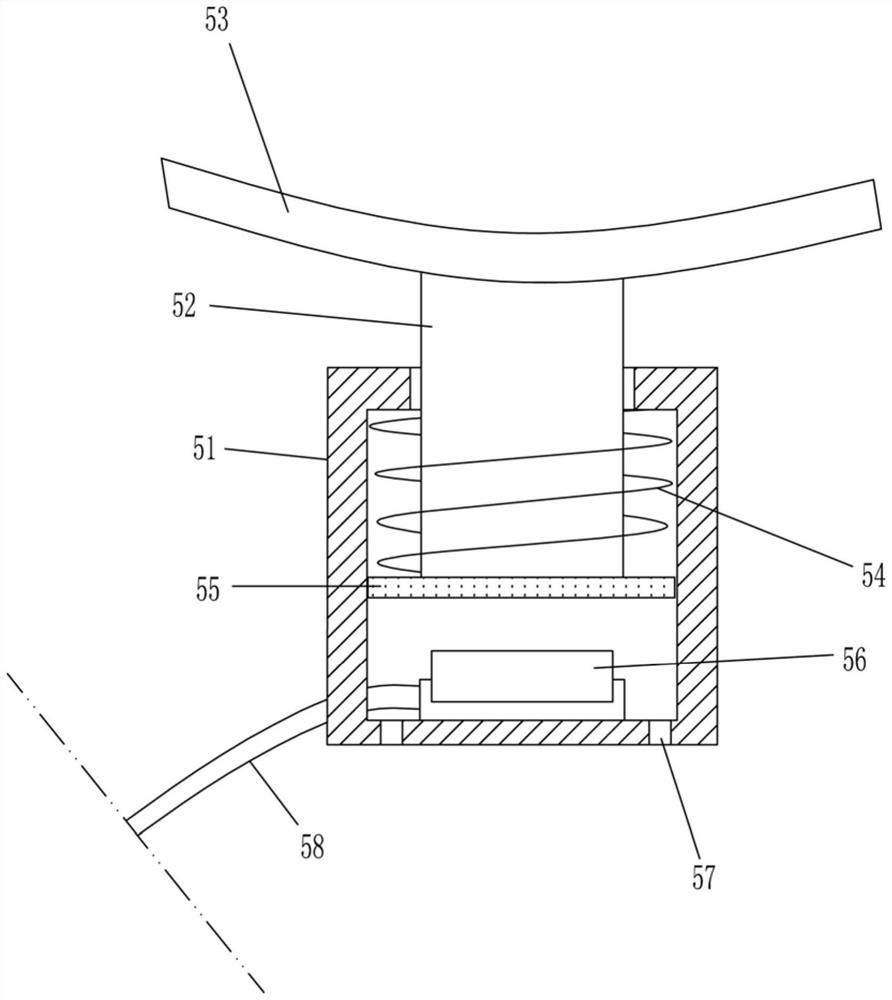

[0031] A fastening type pneumatic punch that can automatically adjust the height, such as Figure 1-8 As shown, it includes a workbench 1, a moving slot 2, a control switch 3, a fastening component 4, a pedal control component 5, a support base 6, a height adjustment component 7, a mounting frame component 8, a buffer device 9, and a stamping connection frame 10 , air pressure gauge 11, air inlet 12, adjustment knob 13, delivery pipe 14, pneumatic cylinder 15, downpressing stroke adjustment device 16, control box 17, counter 18, timer 19 and switch group 20; There is a moving groove 2 for the guided movement of stamping parts; the support seat 6 is fixed on the back wall of the workbench 1; two control switches 3 are fixed on the two side walls of the workbench 1 in turn; the fastening component 4 is fixed on the front wall of the workbench 1 The height adjustment assembly 7 is fixed on the top of the support base 6; the mounting frame assembly 8 is clamped with the output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com