Patents

Literature

35results about How to "Adjustment time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

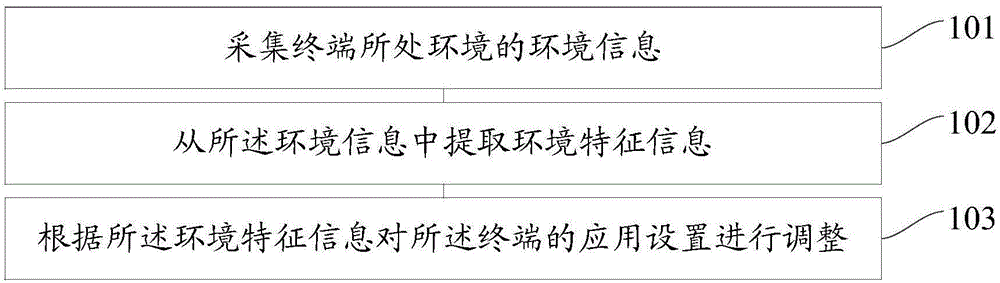

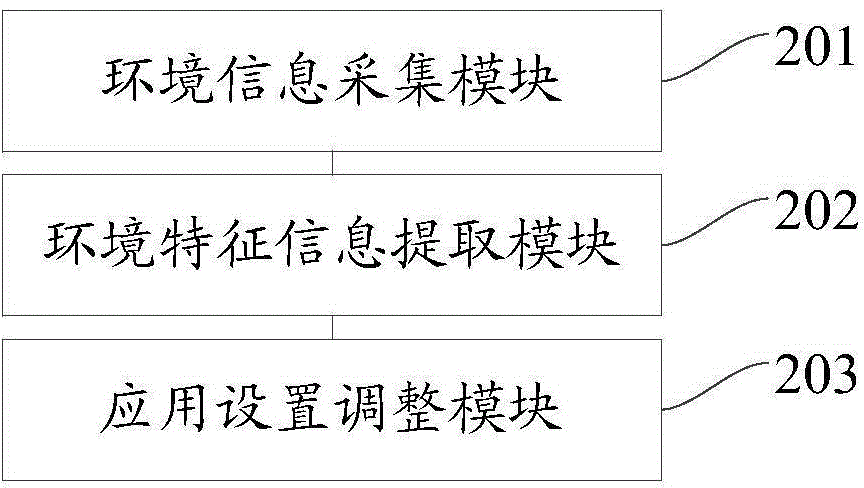

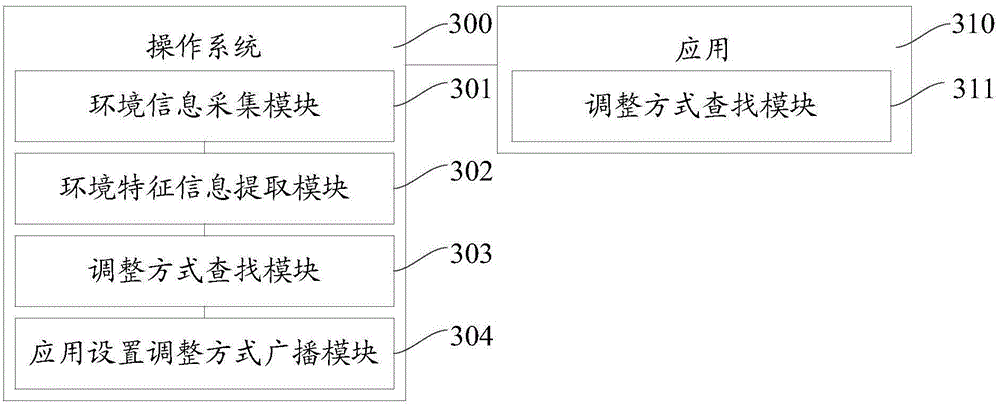

Method, device, and system for adjusting application setting of terminal

InactiveCN105992033AImprove simplicityReduce wasteTelevision system detailsCharacter and pattern recognitionSimulationComputer terminal

Embodiments of the invention provide a method, a device, and a system for adjusting an application setting of a terminal. The method comprises the following steps of acquiring environment information of an environment where the terminal is located; extracting environment feature information from the environment information; and adjusting the application setting of the terminal according to the environment feature information. In the embodiments of the invention, convenience of an operation is greatly improved, an adjustment threshold is reduced, and consumed time for adjustment is shortened; and in reality, the terminal does not need to carry out multiple responses to am adjustment operation of a user so that a waste of system resources is reduced.

Owner:ALIBABA GRP HLDG LTD

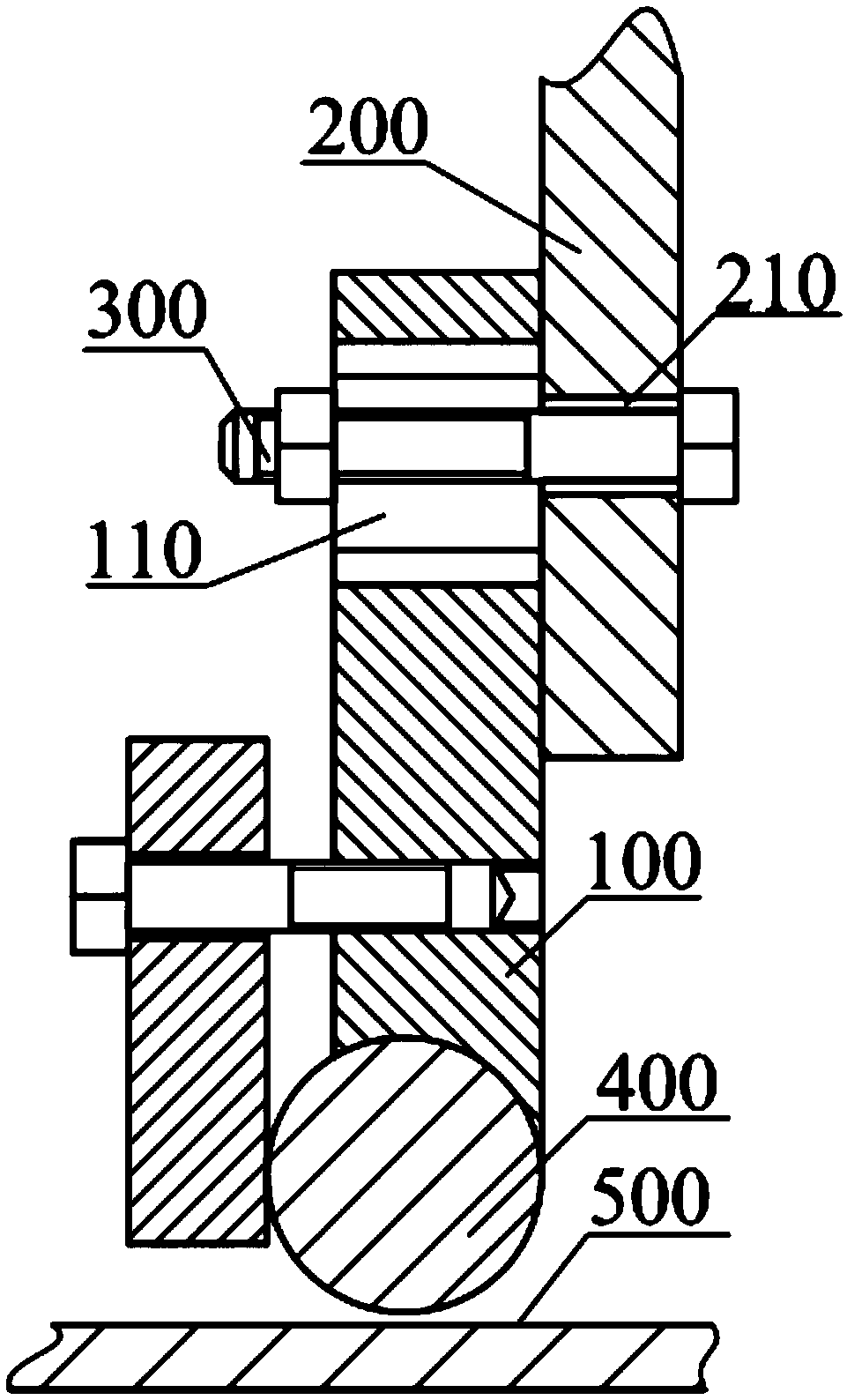

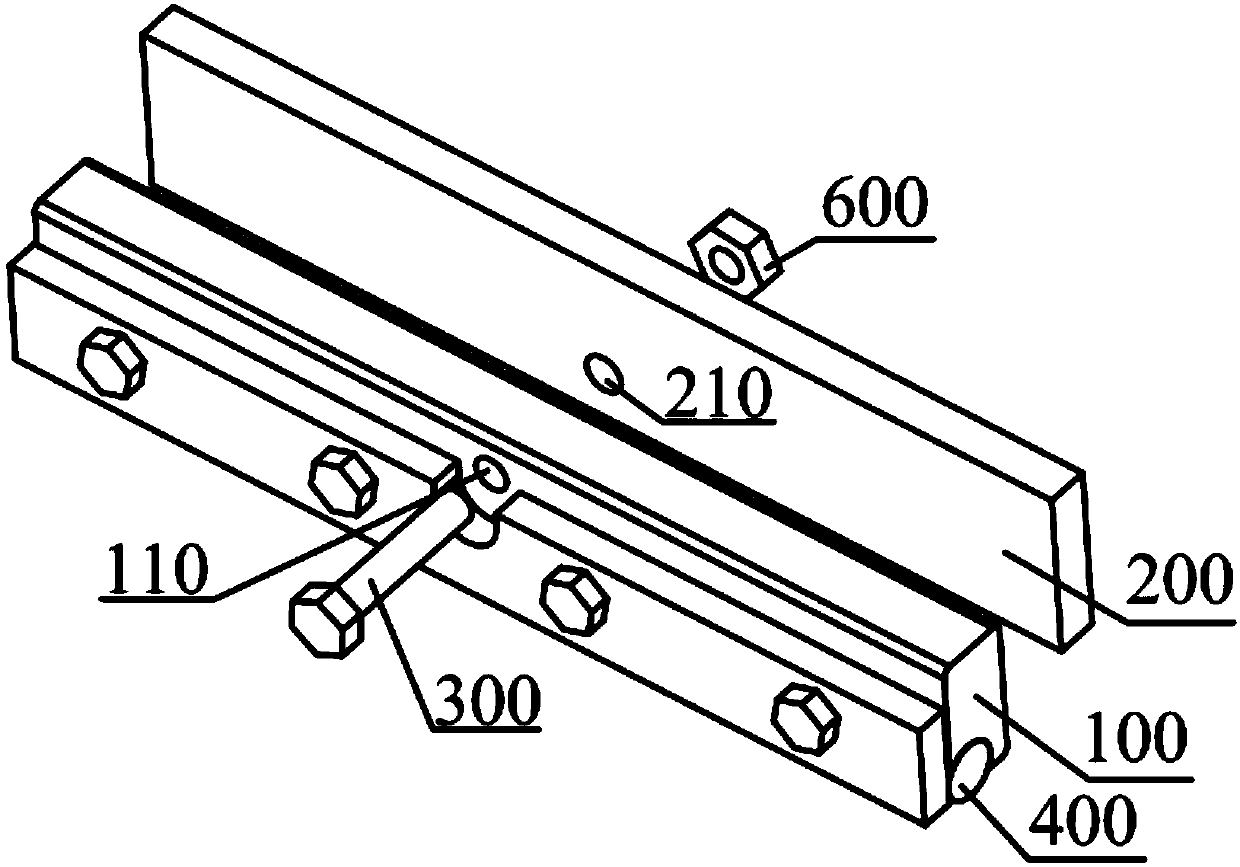

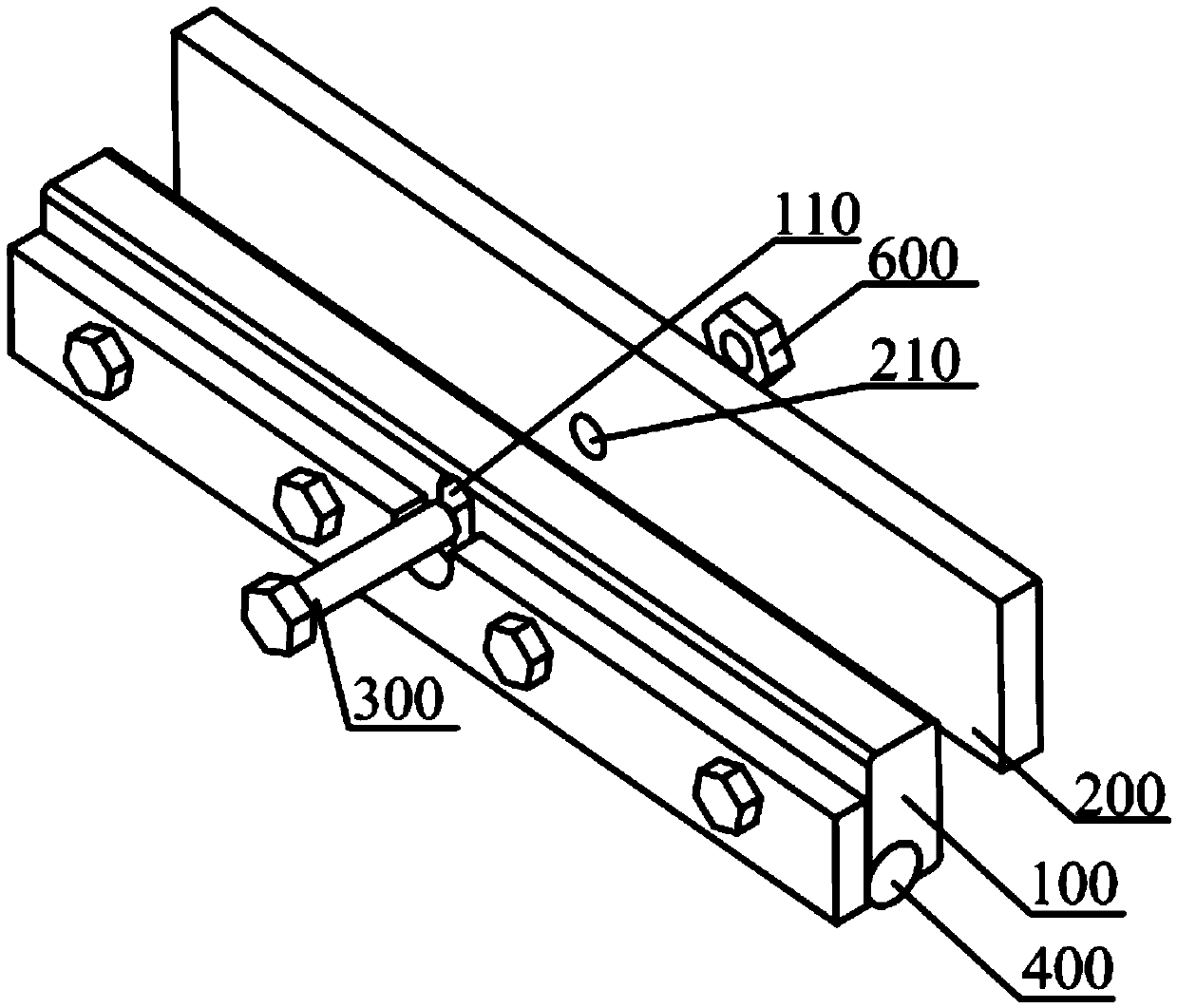

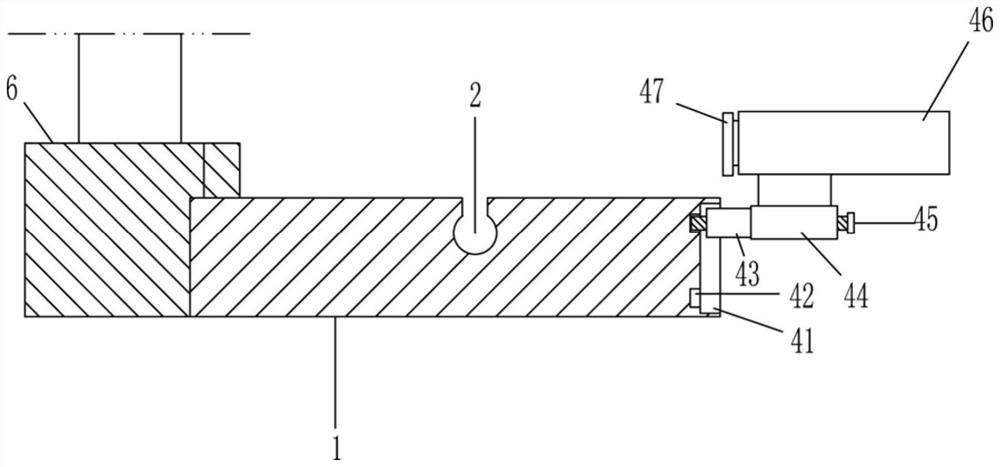

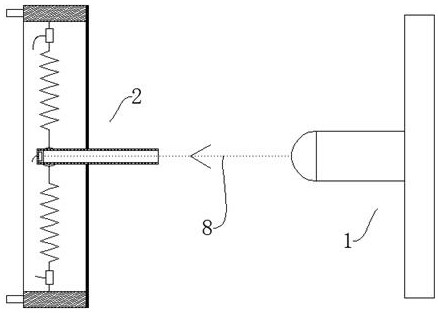

Powder spreading device

InactiveCN109648078AEasy to adjustAdjustment time is shortAdditive manufacturing apparatusIncreasing energy efficiencyBiomedical engineering3D printing

The invention provides a powder spreading device and relates to the field of three-dimensional printing, comprising: a connecting assembly, a scraper holder, a positioning bolt and a scraper. a firstpositioning hole is formed in the connecting assembly; a second positioning hole is formed in the scraper holder; the positioning bolt passes through the first positioning hole and the second positioning hole to fix the connecting assembly on the scraper holder in a detachable manner. The scraper is fixed on the connecting assembly and faces a powder spreading surface. The powder spreading devicehas simple adjustment operation and short adjustment time.

Owner:HANS LASER TECH IND GRP CO LTD

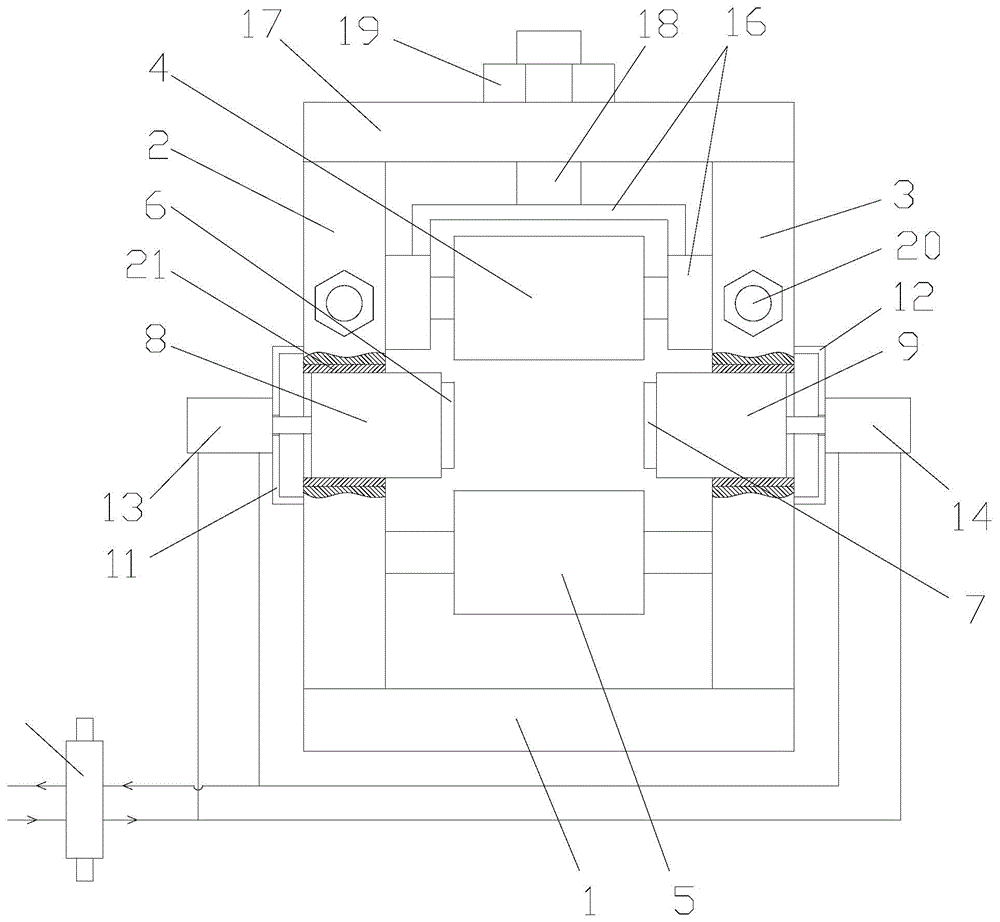

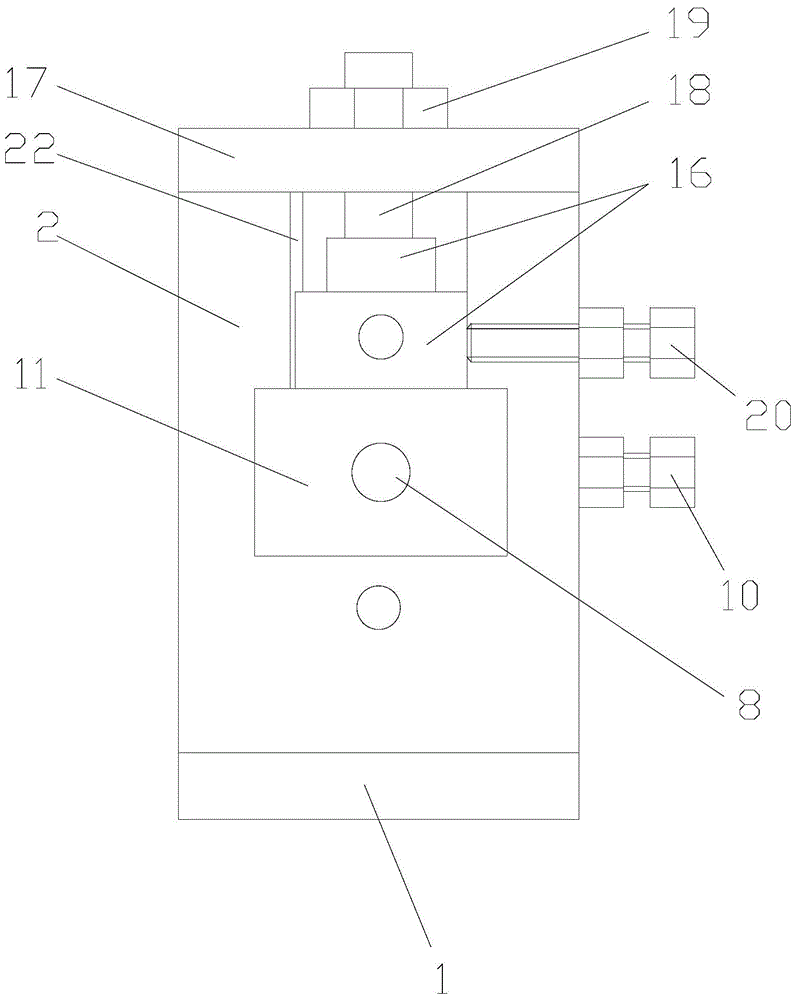

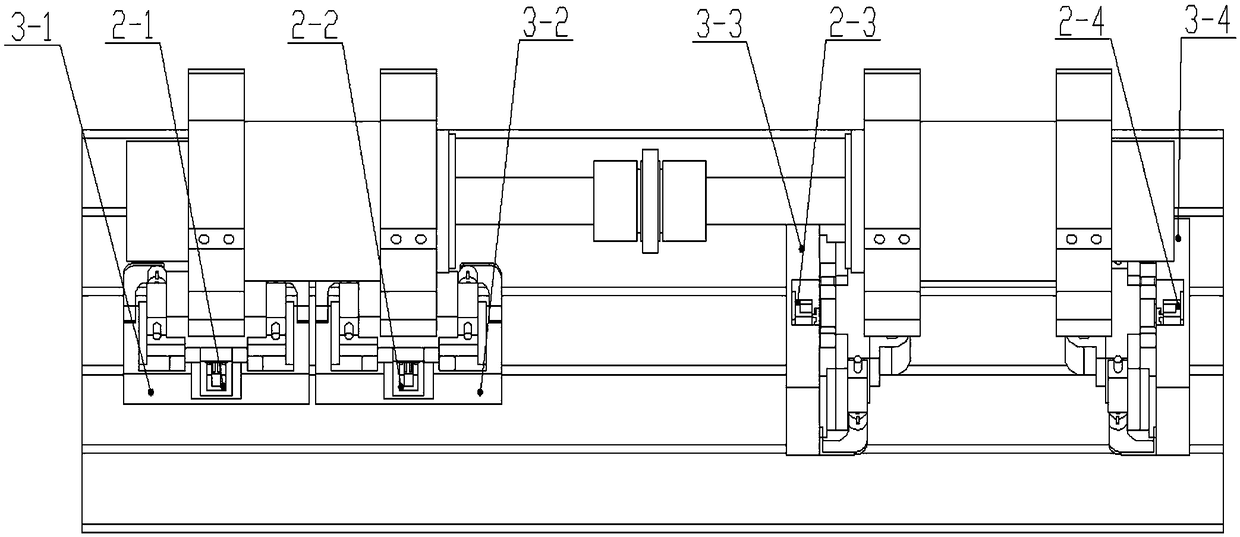

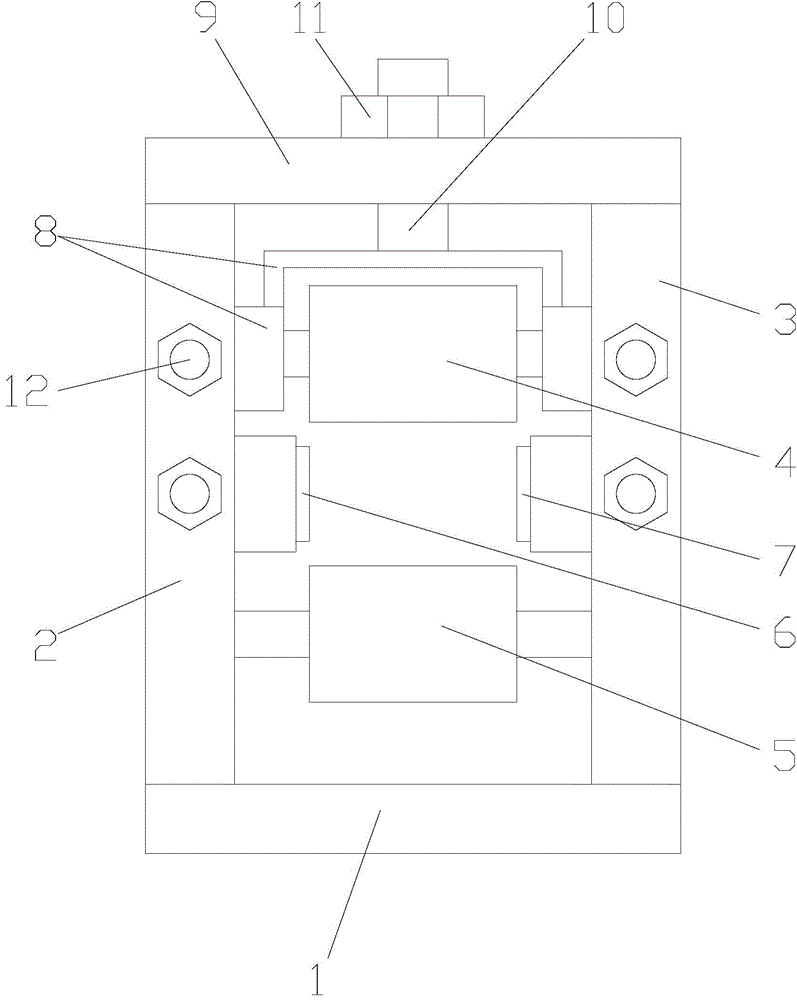

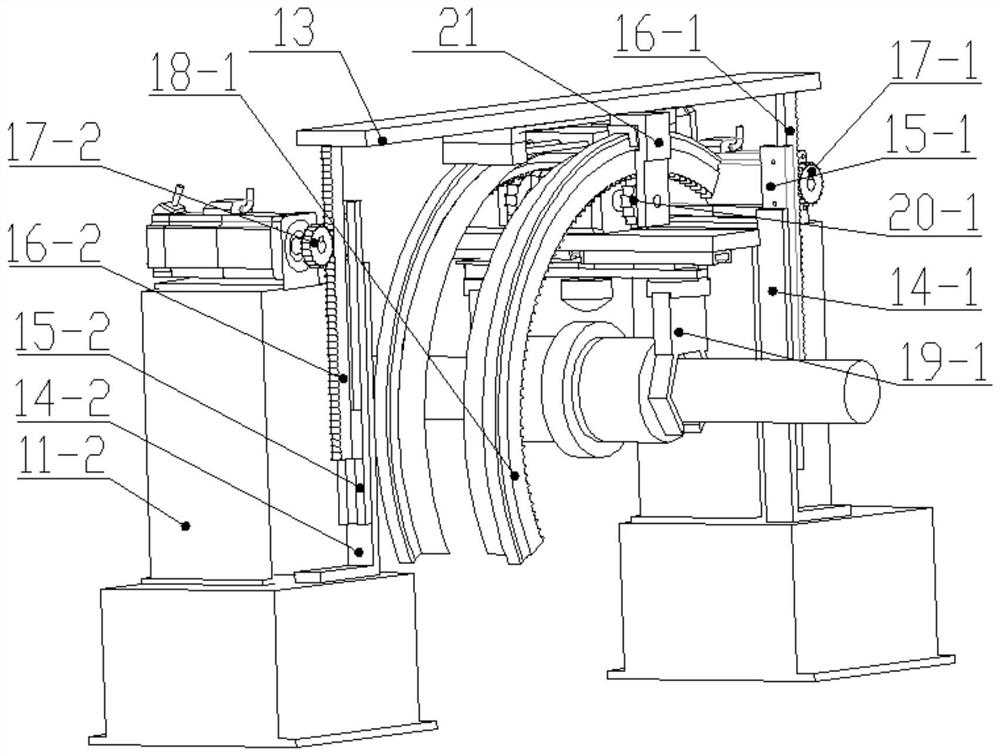

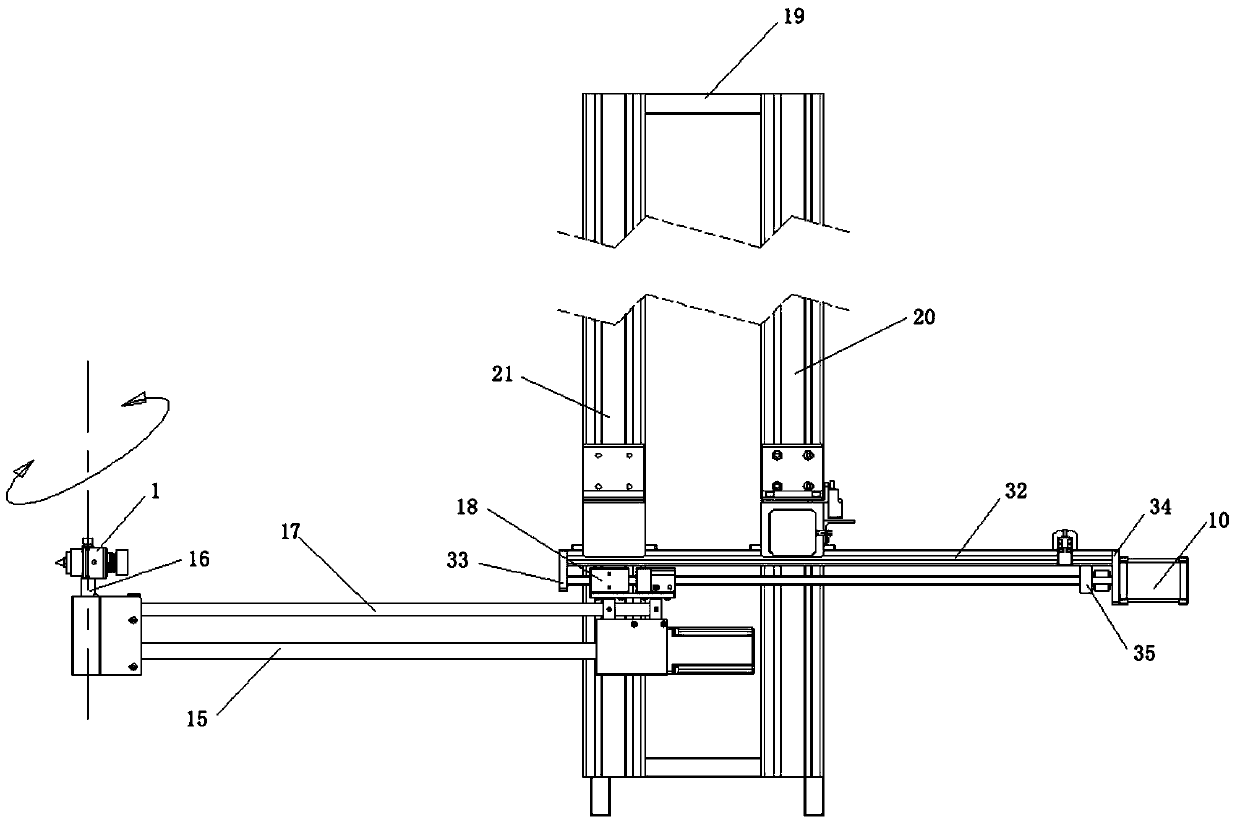

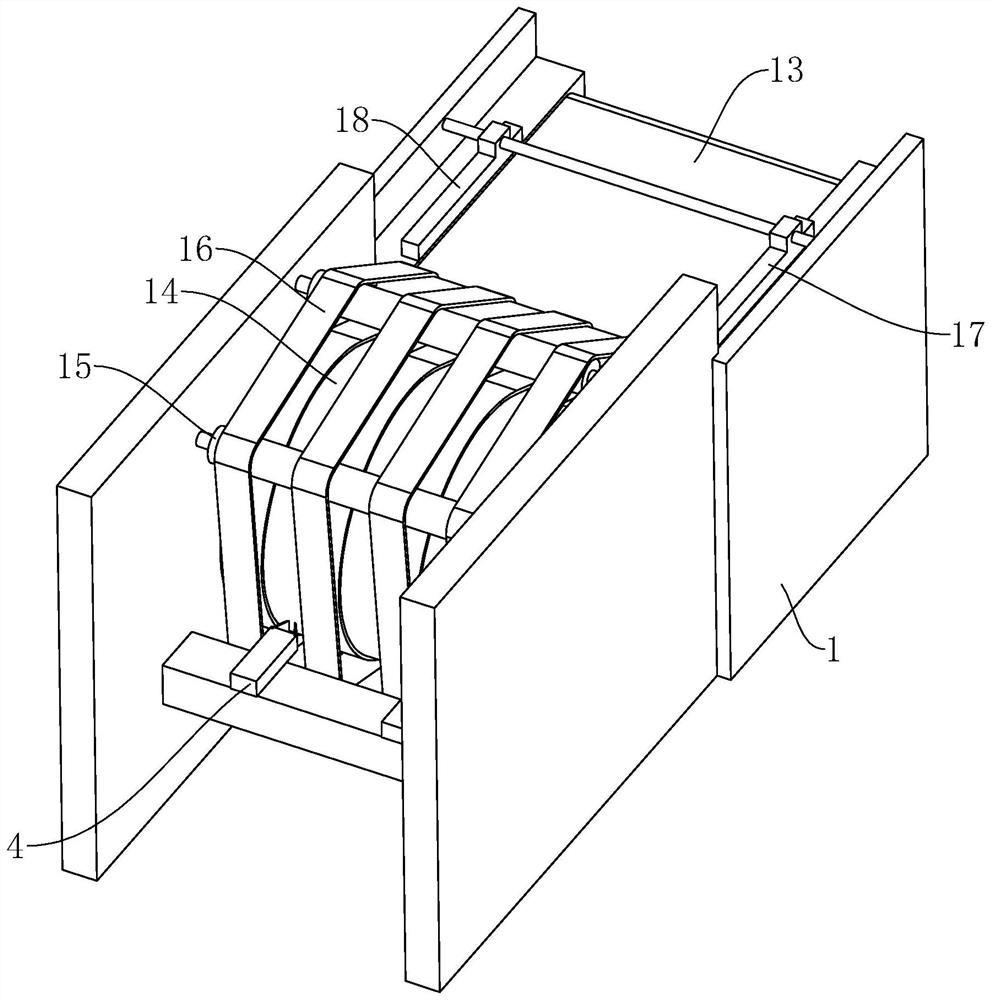

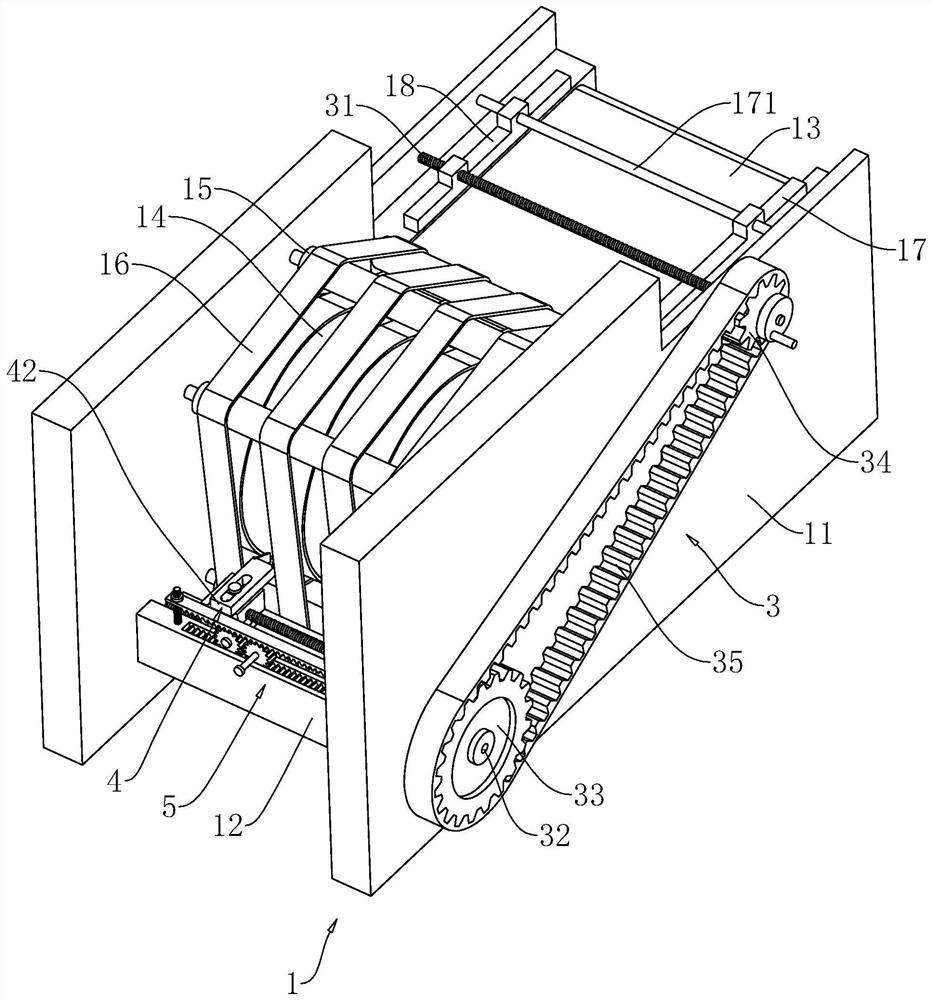

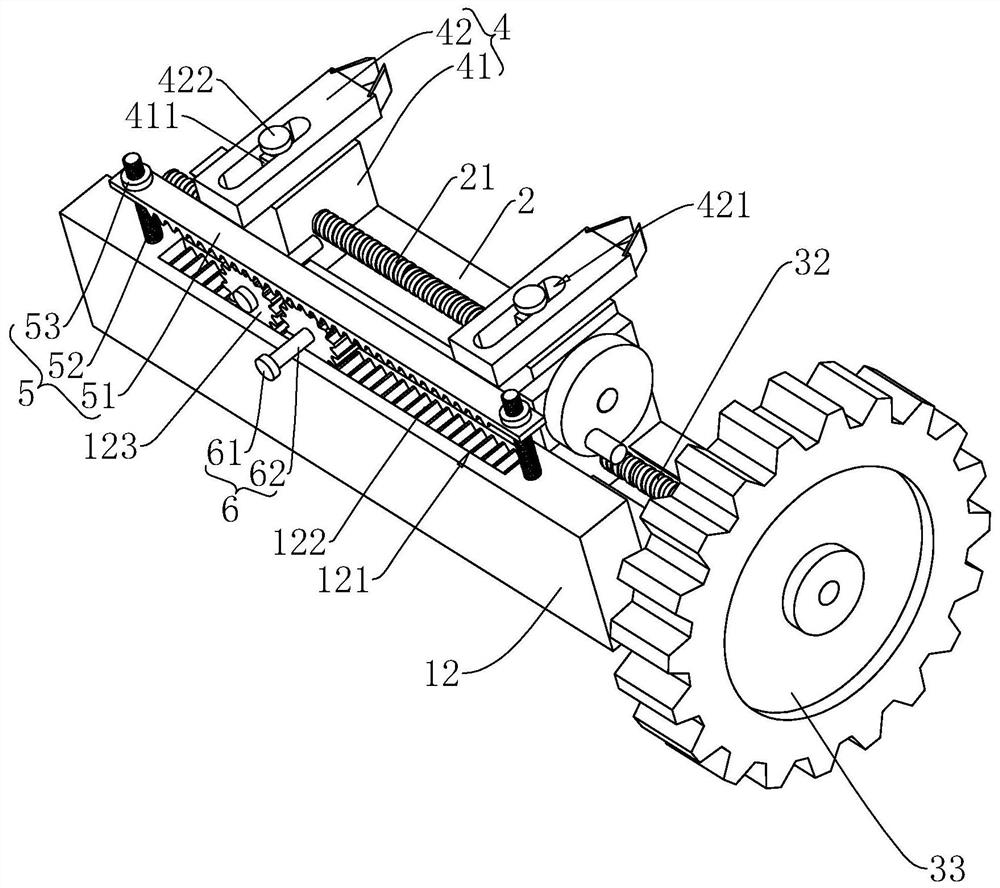

Linkage roll adjustment-type rolling mill for rectangular steel tubes

InactiveCN104384189AGood symmetryEasy to adjustMetal rolling stand detailsMetal rolling arrangementsStrip millEngineering

The invention discloses a linkage roll adjustment-type rolling mill for rectangular steel tubes. The linkage roll adjustment-type rolling mill comprises a base, a left rack, a right rack, a top roll, a bottom roll, a left roll and a right roll; two rectangular guide holes are respectively formed in the left rack and the right rack, and the left rack and the right rack are respectively provided with a left support plate and a right support plate; a left sliding seat and a right sliding seat are respectively arranged in the rectangular guide holes; the left support plate and the right support plate are respectively provided with a cylinder of which the piston rod is connected with the corresponding sliding seat; the linkage roll adjustment-type rolling mill also comprises a reversing valve for controlling the left cylinder and the right cylinder; the linkage roll adjustment-type rolling mill also comprises an arch adjusting bracket, a cross beam, a lifting rod and a locknut. According to the linkage roll adjustment-type rolling mill disclosed by the invention, the sliding seats are respectively pushed by the cylinders to adjust the left roll and the right roll in position, and moreover, the left cylinder and the right cylinder are controlled by the identical reversing valve, so that the left roll and the right roll are equal in amount of movement; moreover, the arch adjusting bracket is connected with the left end and the right end of the top roll, and the top roll is adjusted by the lifting screw rod to rise and fall; roll adjustment is convenient, the adjustment time is short, and the work efficiency is high.

Owner:CHONGQING LONGSHAN METAL MATERIAL

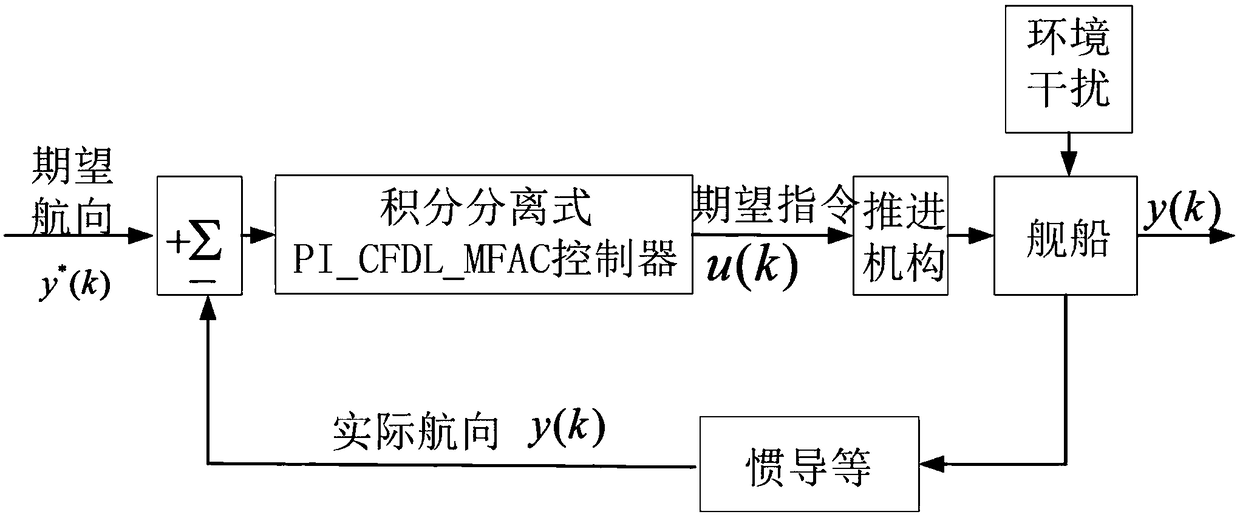

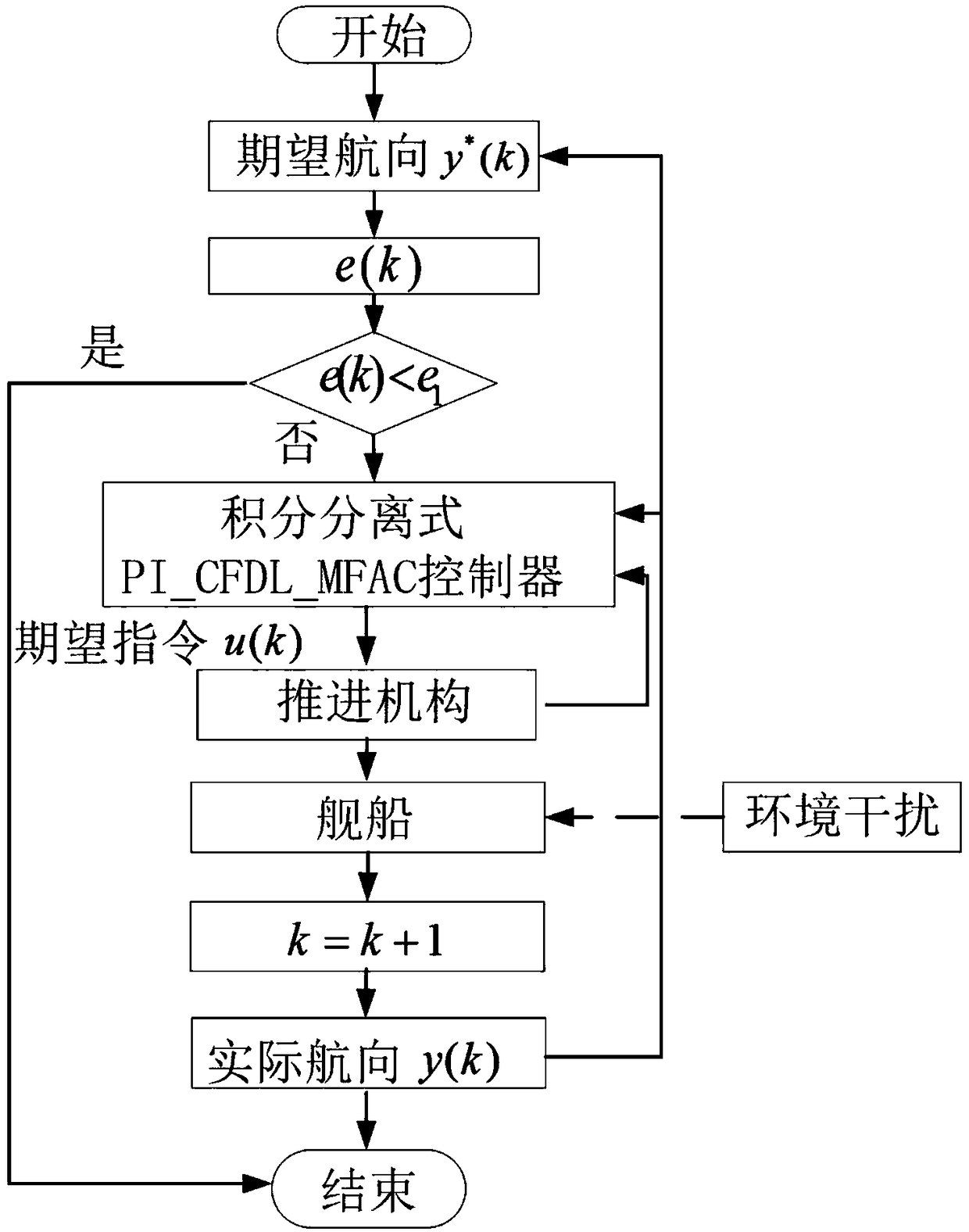

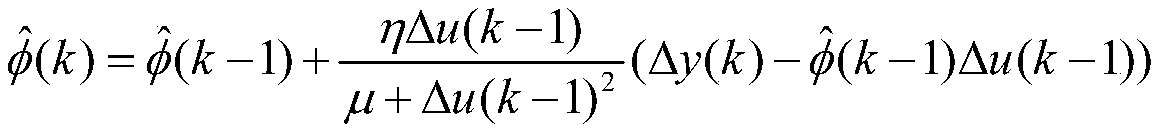

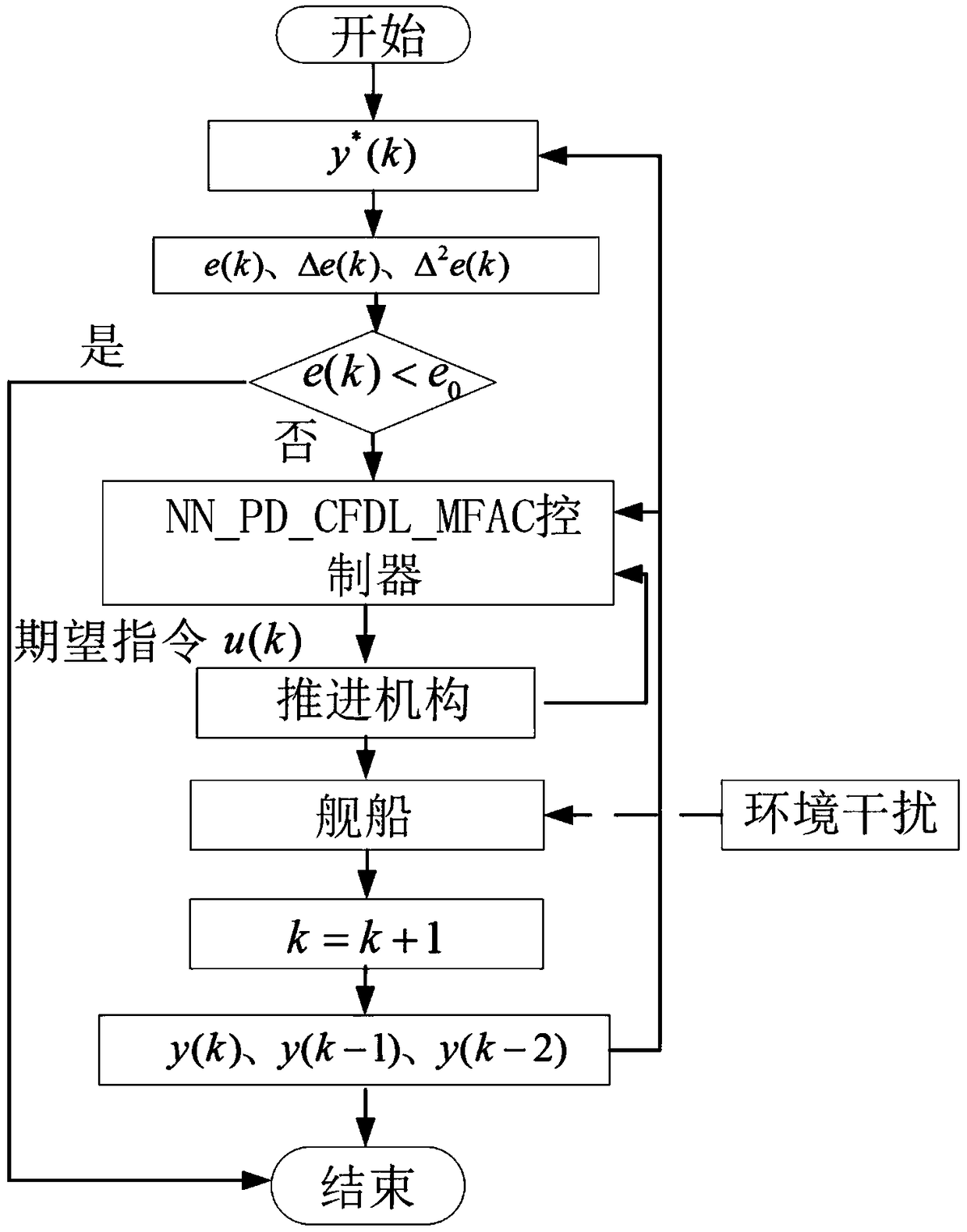

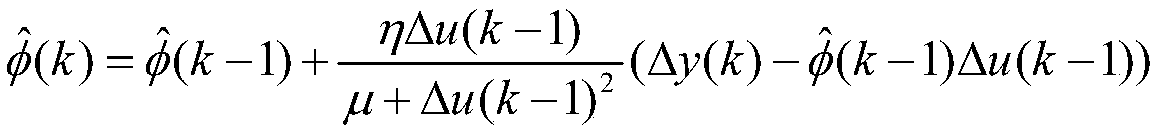

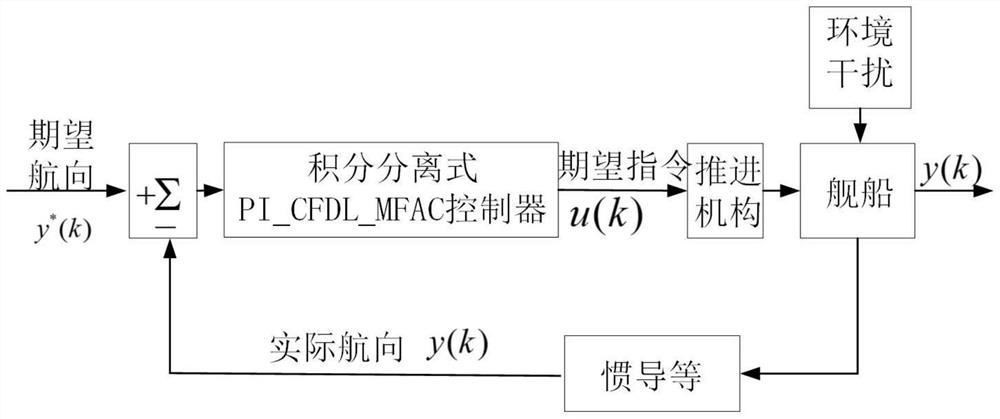

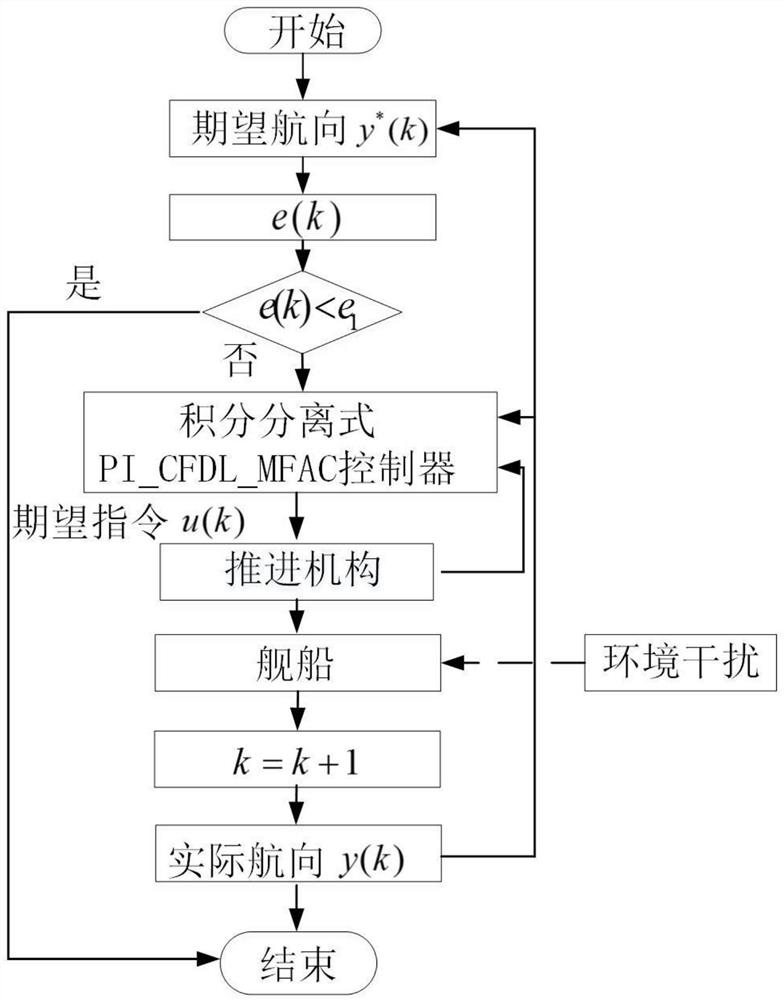

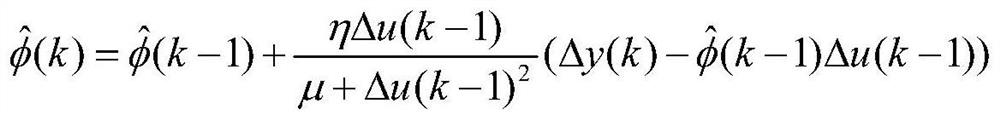

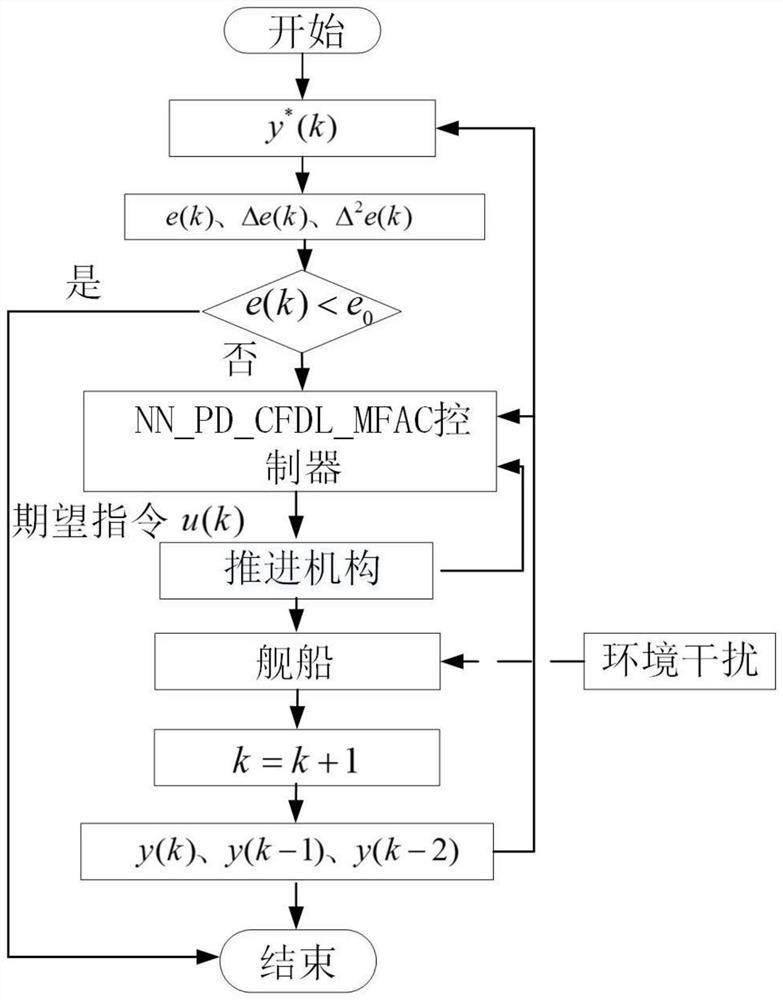

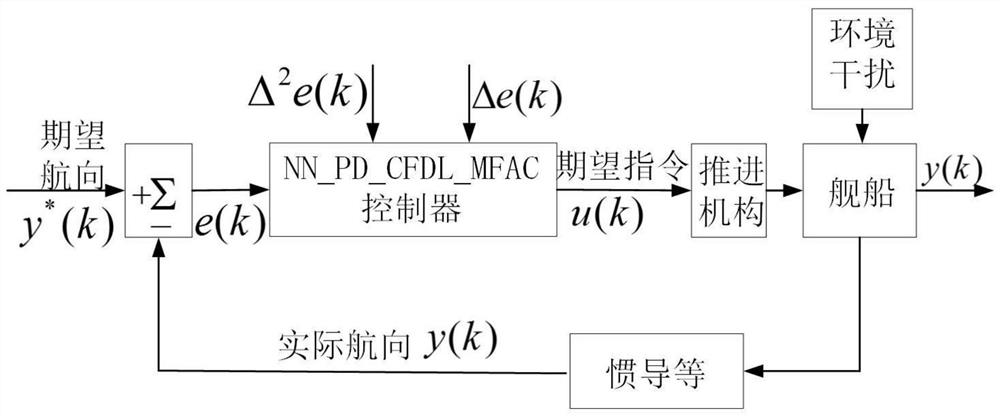

Integral separation type PI-Type tight format model free adaptive course control algorithm used for ships

ActiveCN109144066AConvergent stabilityQuick responseControllers with particular characteristicsPosition/course control in two dimensionsSelf adaptiveDiscrete form

The invention belongs to the field of ship motion control, and specifically relates to an integral separation type PI-Type tight format model free adaptive course control algorithm used for ships. Thealgorithm includes the following steps: a proportional item is introduced to form a PI-type CFDL_MFAC algorithm based on the tight format model free adaptive control algorithm, and a discrete form ofthe proportional item is k.[delta]e(k); a course deviation threshold e<0> is set; a course deviation e(k) is calculated, wherein e(k)=y<*>(k)-y(k); when an absolute value |e(k)| of the e(k) is greater than a threshold e<1> of a set course state deviation; according to the e(k), an integral separation type PI_CFDL_MFAC controller resolves expected input u(k) of a course system; and a formula ofk=k+1 is achieved, and a current course y(k) of a course ship is updated. By introduction of the proportional item in the control algorithm, the response speed of a system is improved; an idea of integral separation is introduced in the algorithm, thus avoiding the problem that an original control algorithm is directly applied to ship course control to cause system oscillation or even instabilitydue to integral saturation; and introduction of the proportional item and the integral separation idea makes an application range of a CFDL_MFAC theory extend, so that a ship course can quickly and stably converge to a desired course.

Owner:HARBIN ENG UNIV

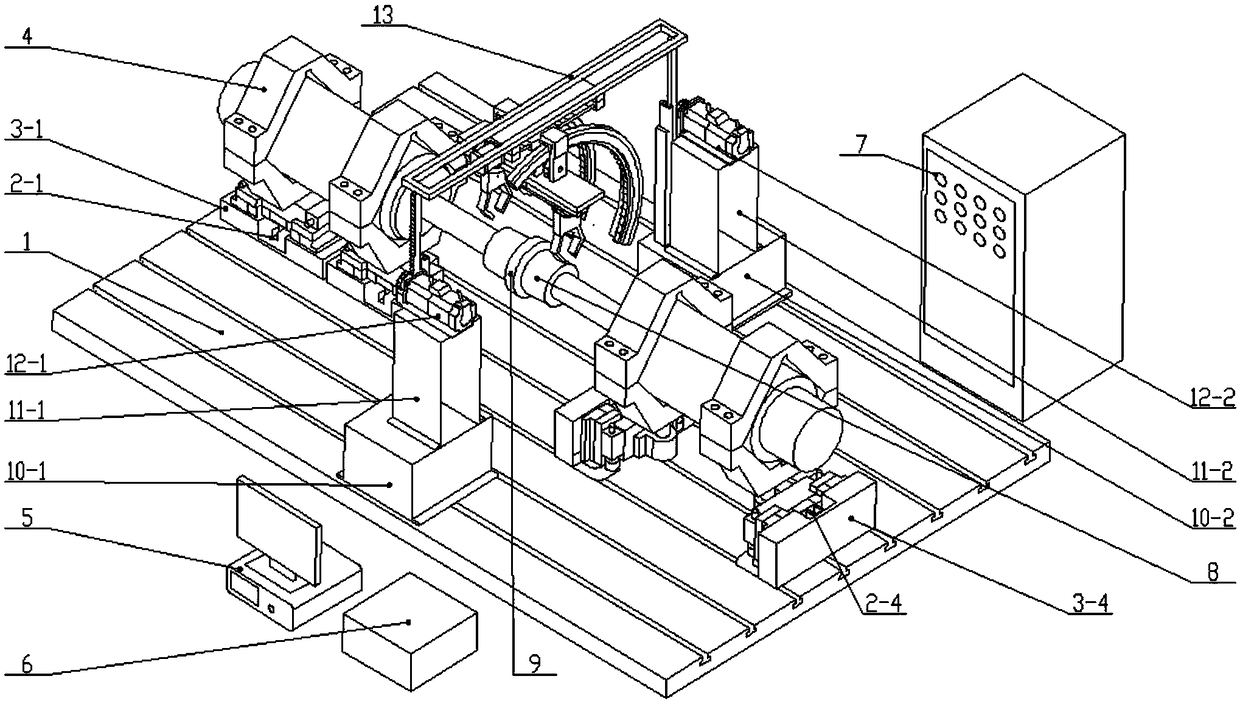

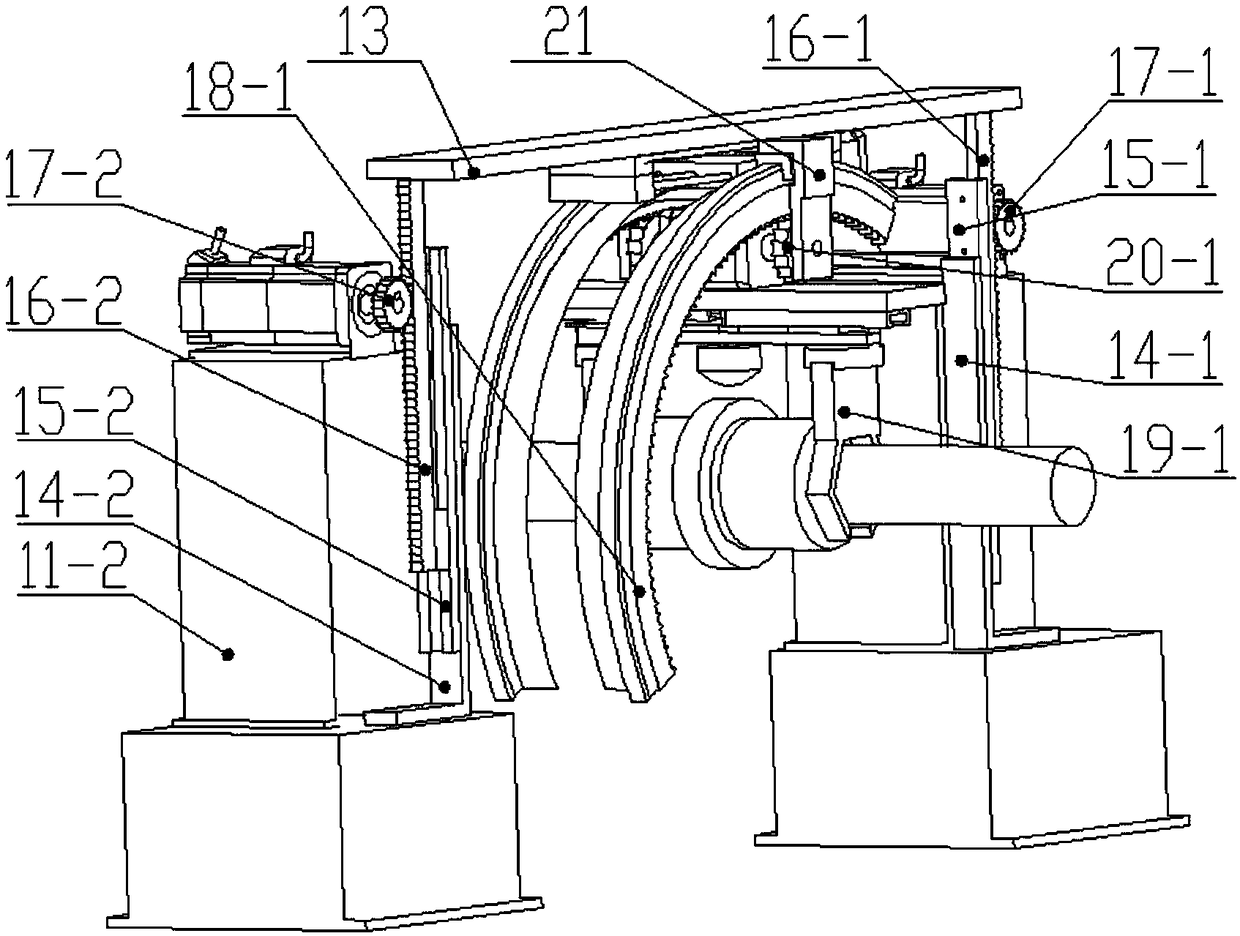

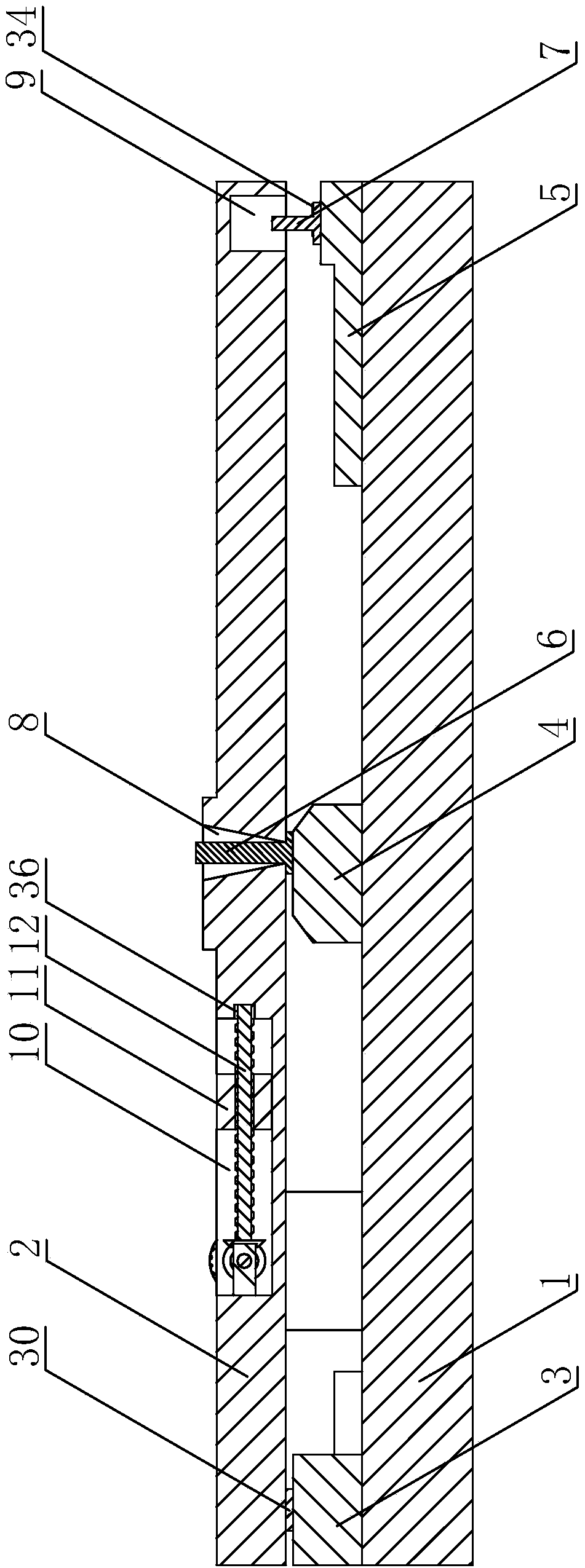

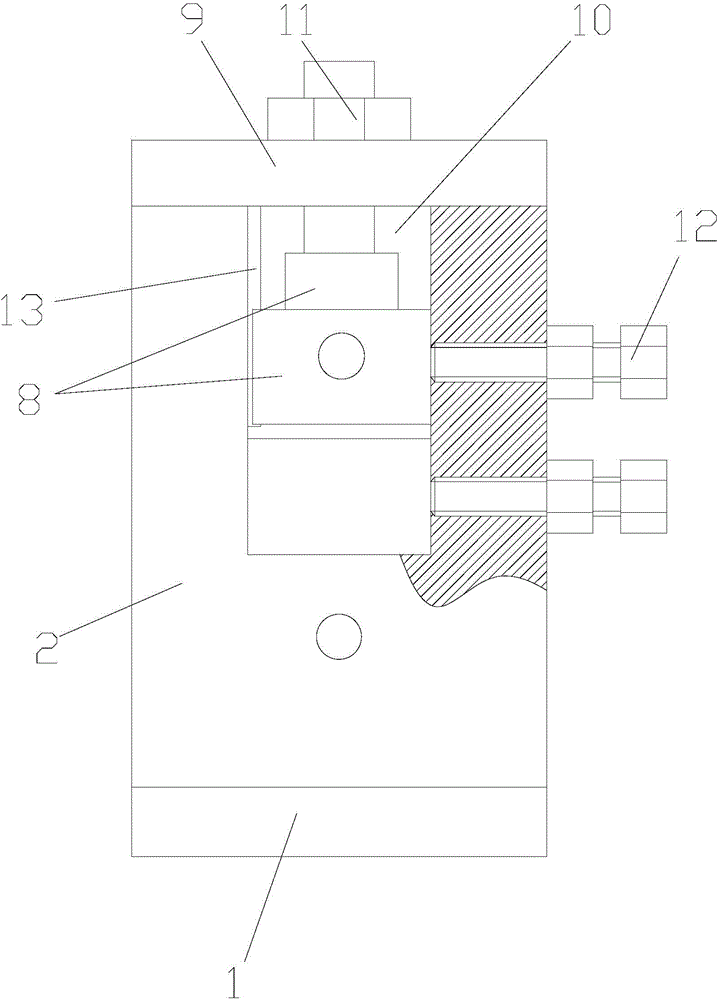

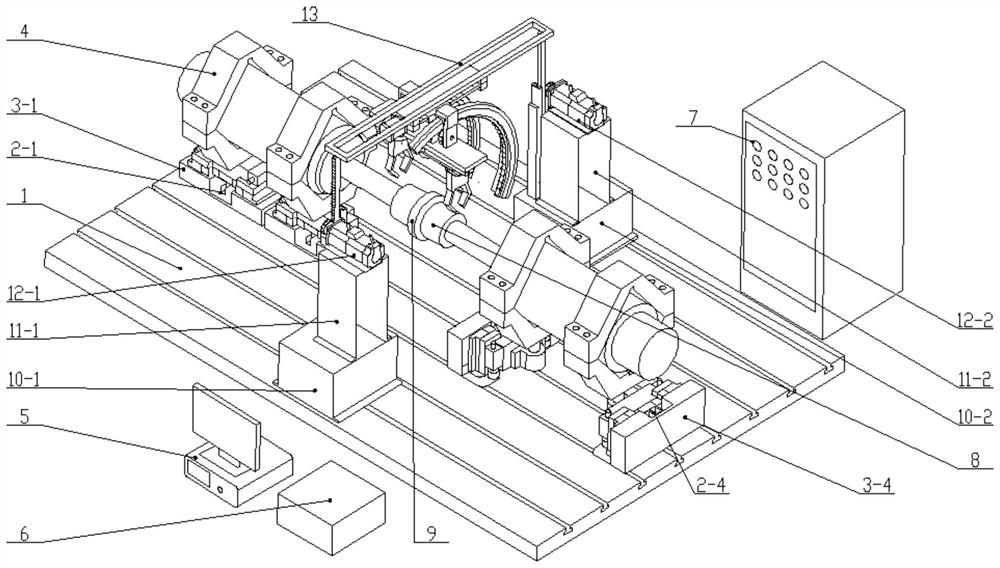

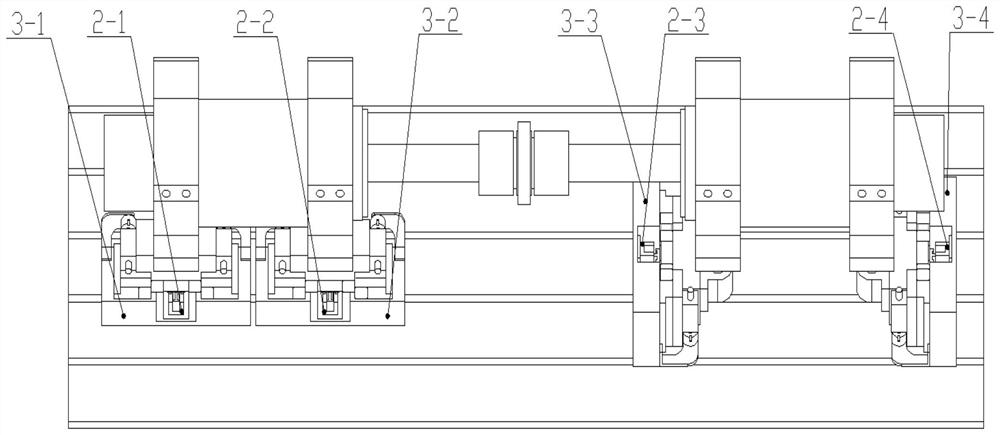

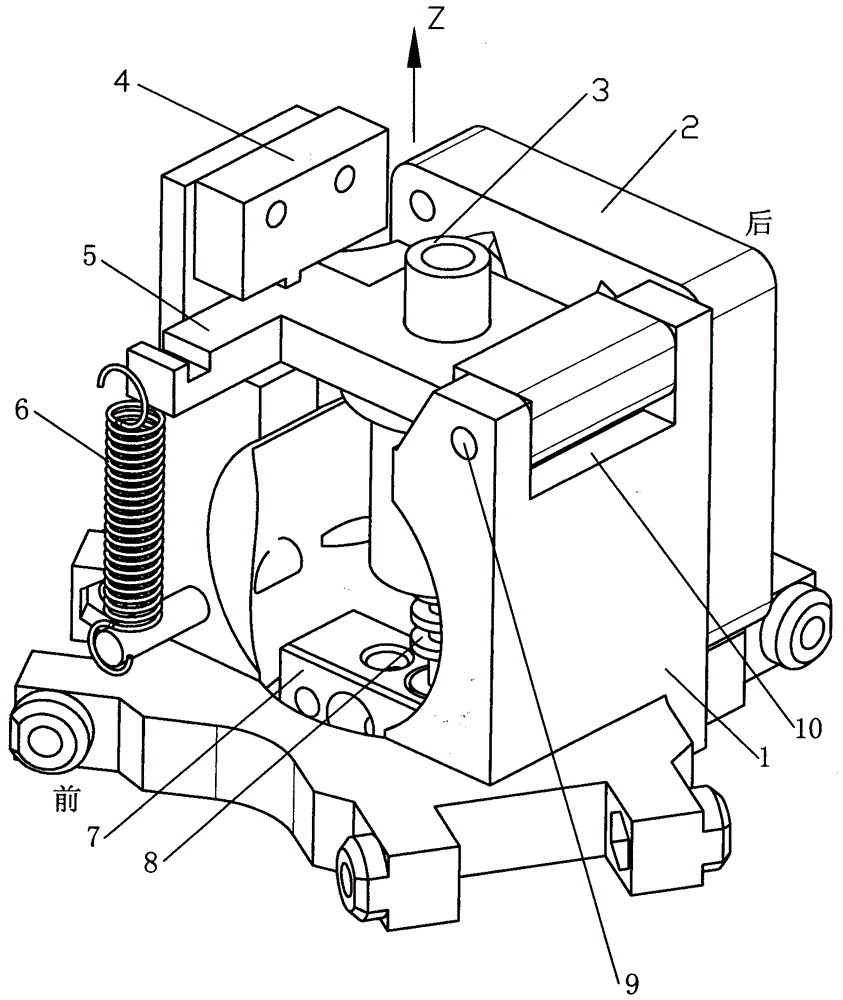

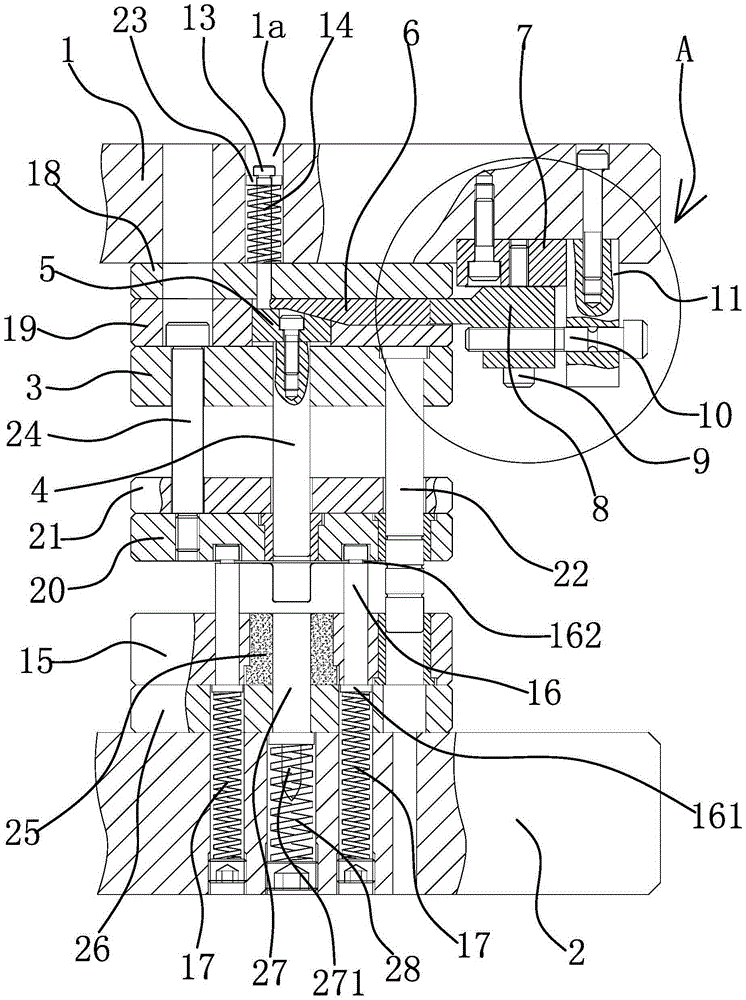

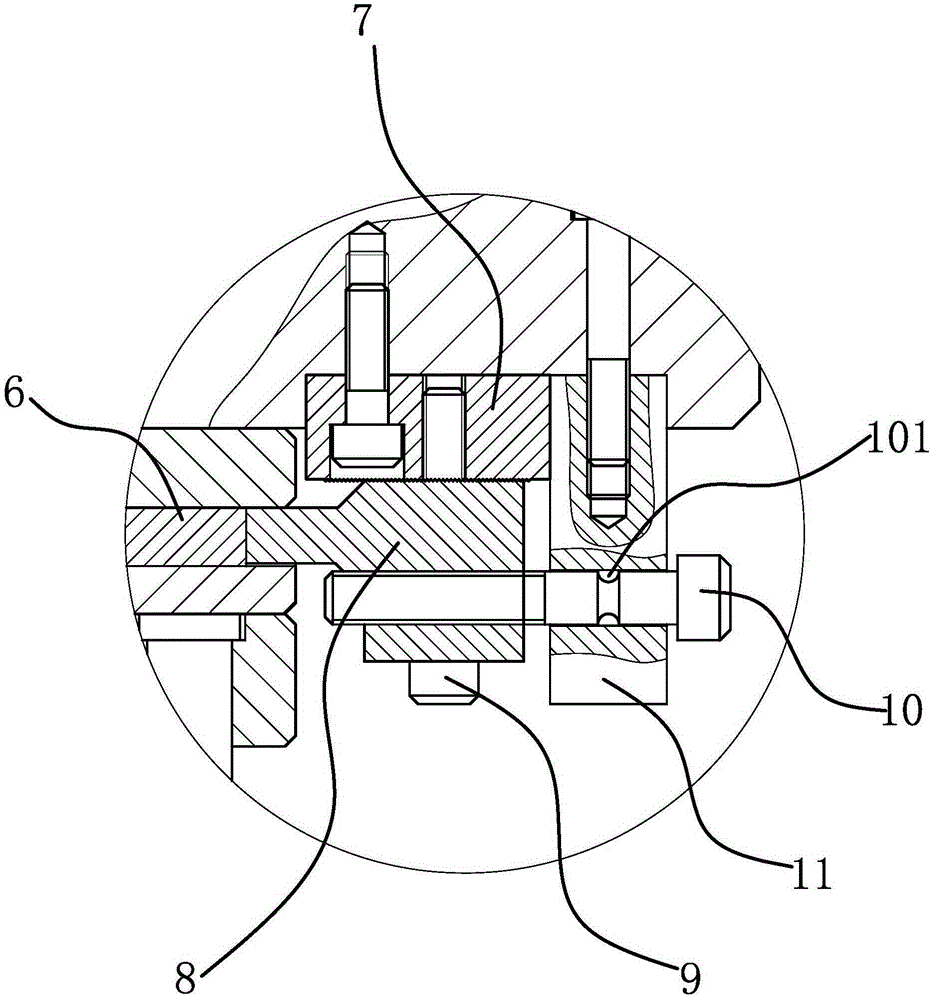

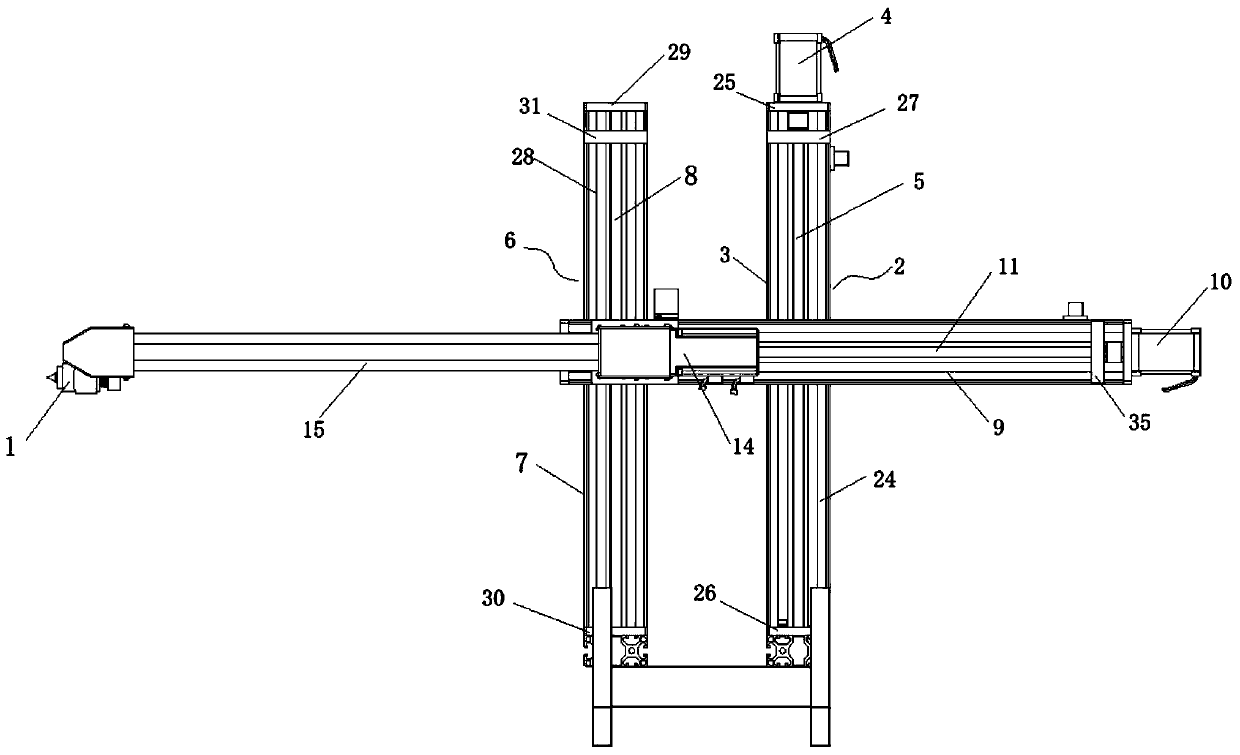

Automatic centering device of electric spindle reliability test platform based on drag loading

The invention discloses an automatic centering device of an electric spindle reliability test platform based on drag loading, and aims to solve the problems of incapable of timely monitoring generation of singularity and elimination and time and labor wasting when adjusting centering of the test platform, the device comprises a spindle position adjusting part, a detection part and a monitoring andautomatic control part; the detection part comprises a supporting device, a feeding device and a detection device; the spindle position adjusting part is arranged at the middle position of an horizoniron through a first to forth static pressure sliding platform, wherein the first static pressure sliding platform and the second static pressure sliding platform are arranged at the left side of thehorizon iron, and the third static pressure sliding platform and the fourth static pressure sliding platform are arranged at the right side of the horizon iron; the detection part is arranged at themiddle position of the horizon iron through a first supporting base and a second supporting base, supporting devices are arranged at the front side and rear side of the spindle position adjusting part, and the feeding device is arranged on the supporting devices; a first laser centering instrument and a second laser centering instrument in the detection device are fixed on a fixing plate in the feeding device; and the monitoring and automatic control part is connected with the spindle position adjusting part and the detection part through wires.

Owner:JILIN UNIV

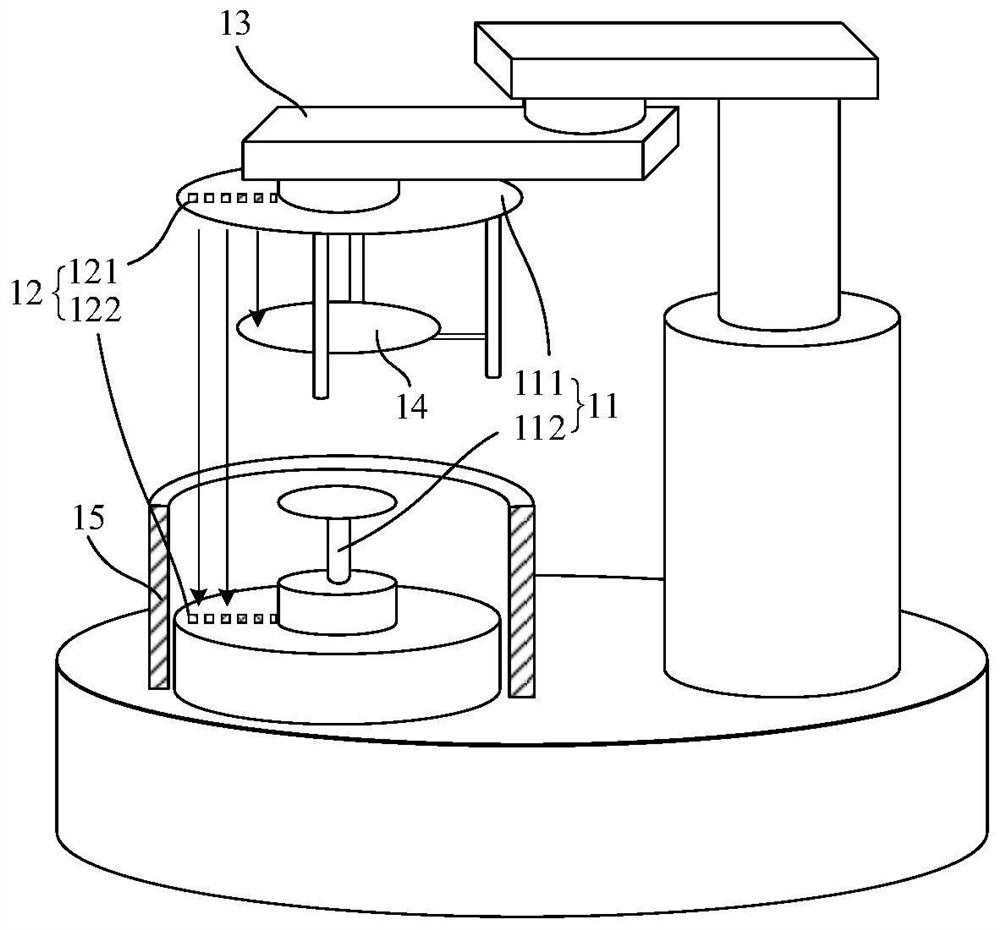

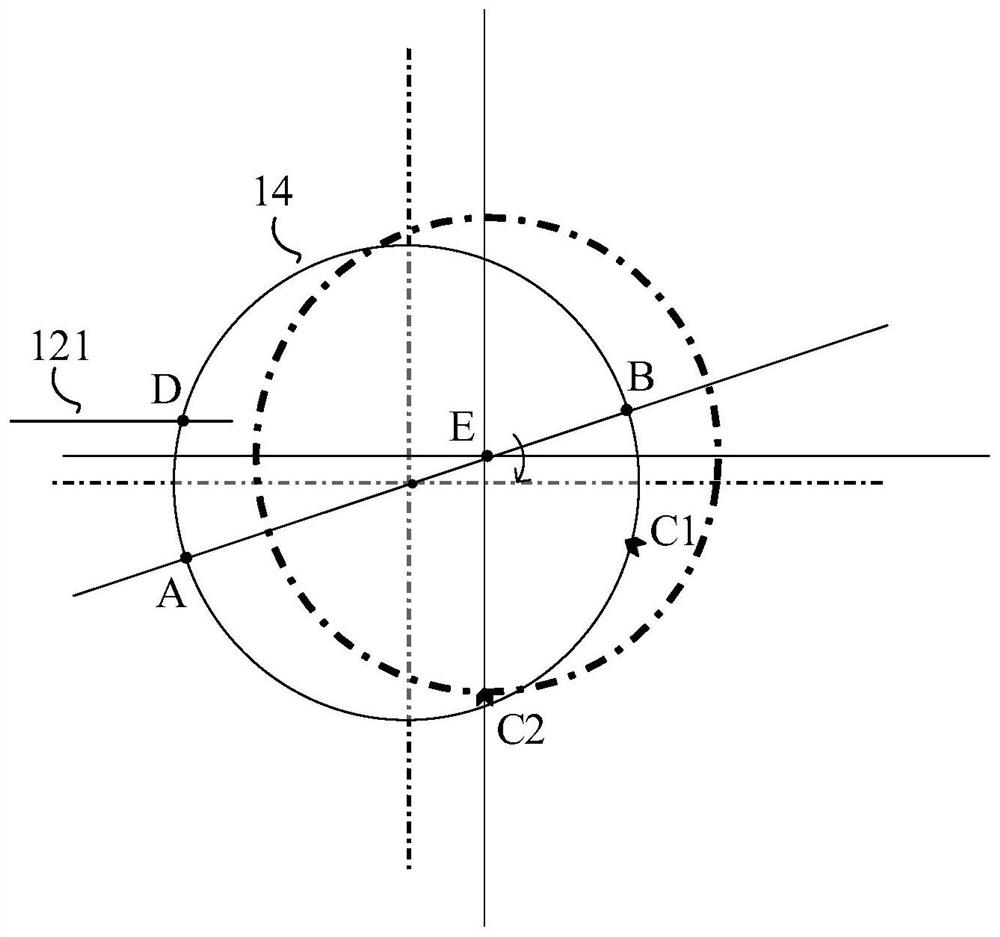

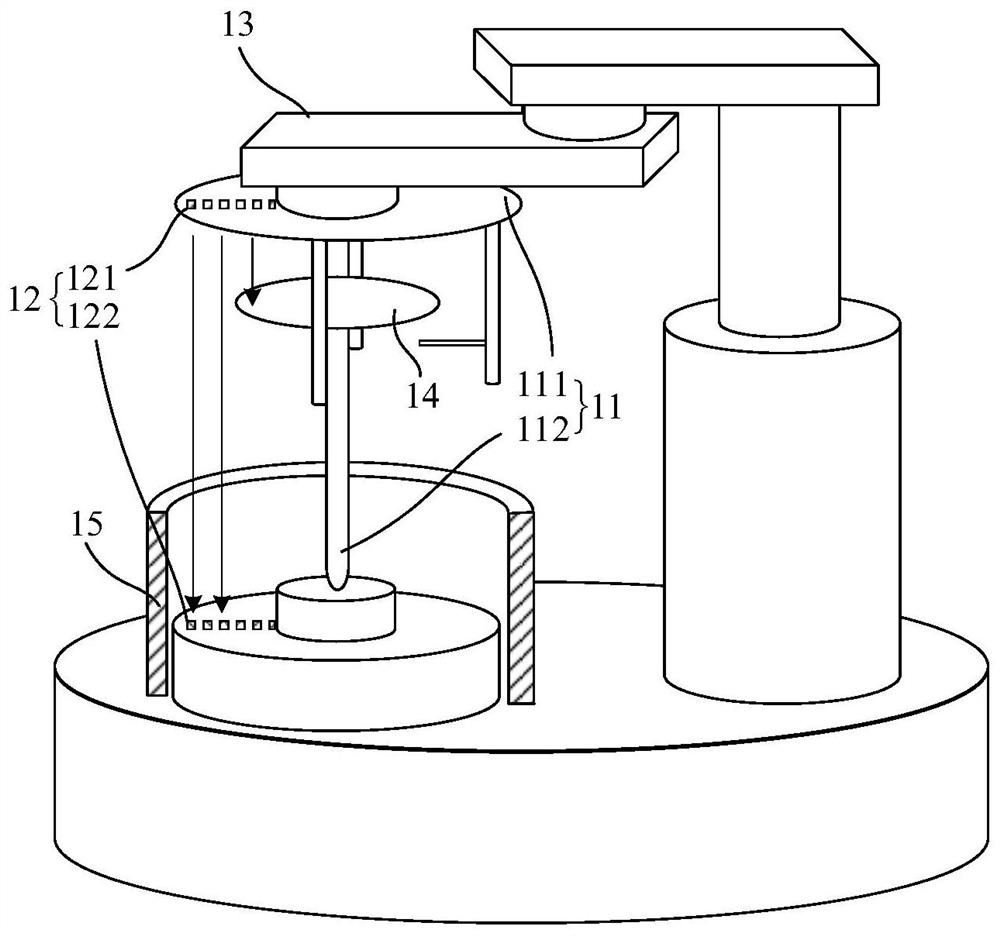

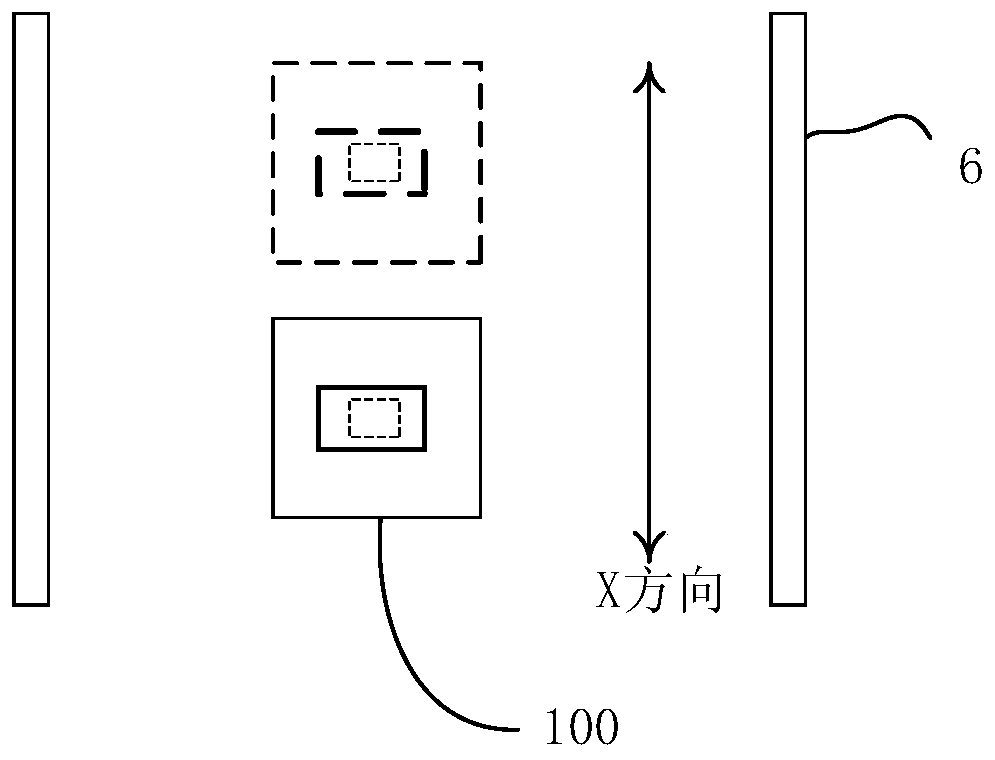

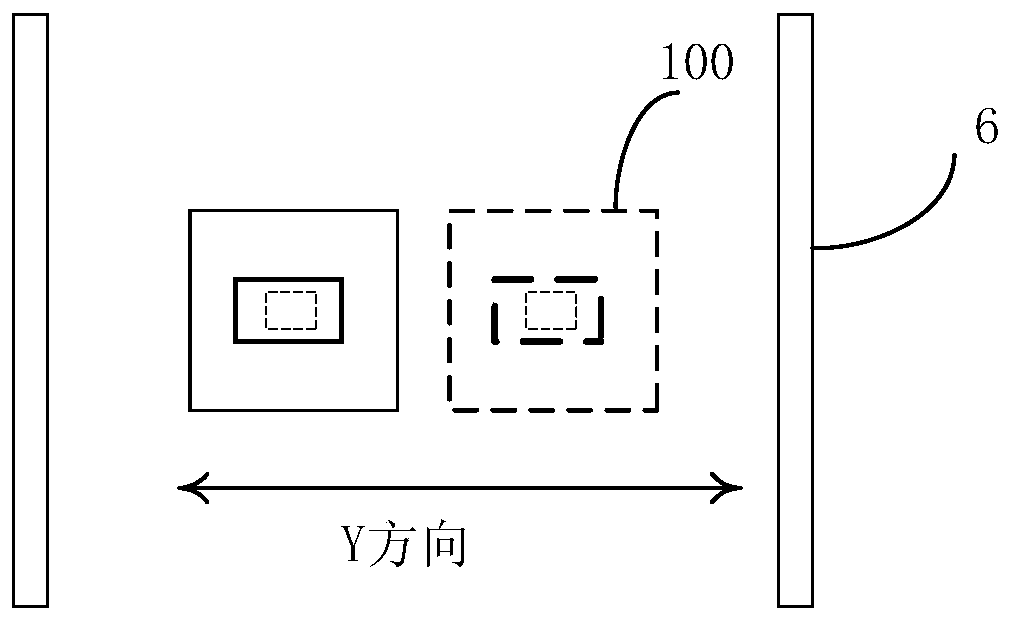

Wafer adjusting device and method and wafer conveying system

PendingCN112908887AAdjustment time is shortSemiconductor/solid-state device manufacturingConveyor partsWaferControl engineering

The embodiment of the invention relates to a wafer adjusting device and method and a wafer conveying system. The wafer adjusting device comprises a bearing part and a detection device, wherein the detection device is used for detecting a wafer to obtain detection information; an adjusting device which is connected with the first bearing assembly and the second bearing assembly in the bearing component, drives the first bearing assembly to move relative to the second bearing assembly and drives the second bearing assembly to move relative to the first bearing assembly; and an analysis controller which is connected with the detection device and the adjusting device, receives the detection information of the detection device, analyzes and processes the detection information, and sends a processing signal to the adjusting device according to a processing result, and the adjusting device drives the first bearing assembly to move relative to the second bearing assembly and drives the second bearing assembly to move relative to the first bearing assembly according to the processing signal. According to the invention, the deviation condition of the deviated wafer can be detected, and corresponding position adjustment can be carried out according to the deviation condition.

Owner:CHANGXIN MEMORY TECH INC

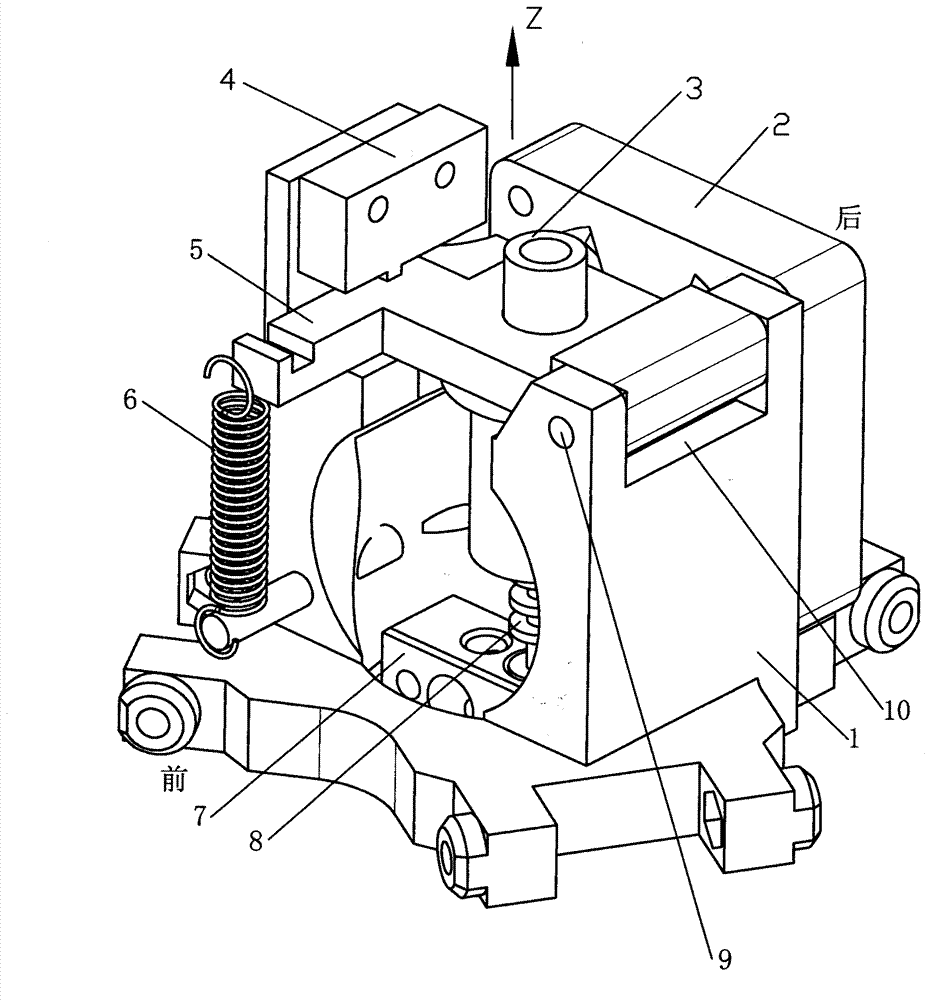

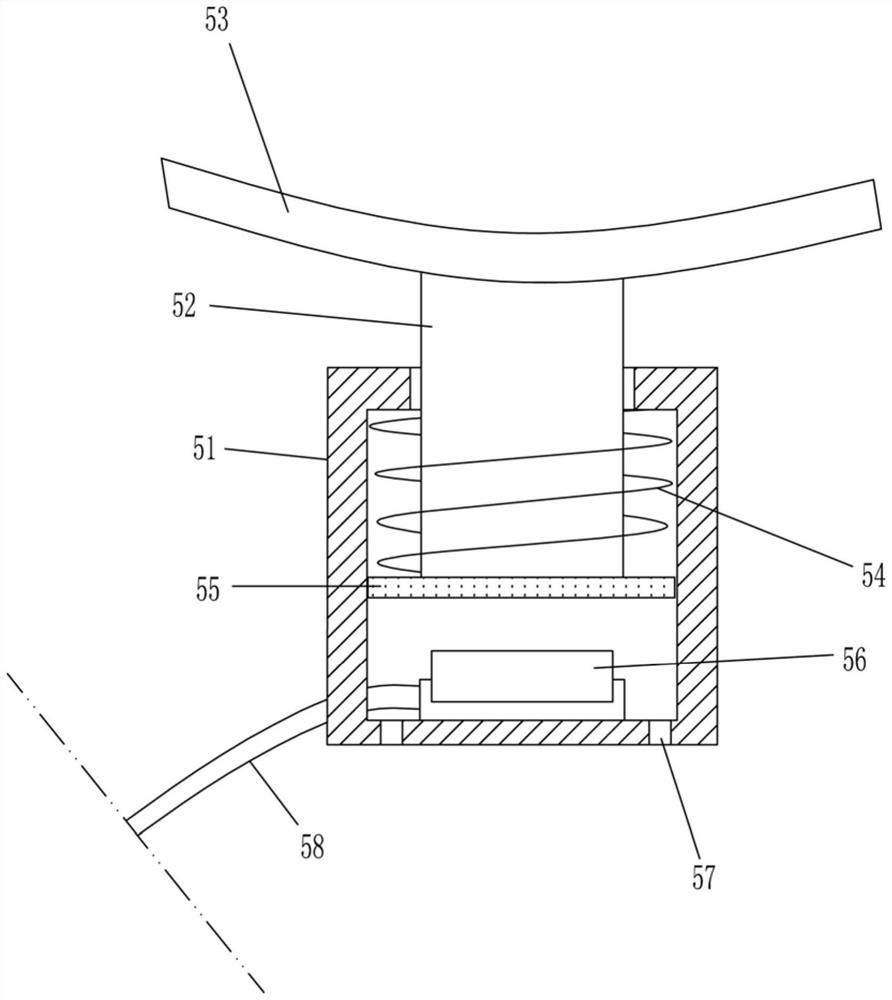

Automatic leveling mechanism for parallel transmission structure

ActiveCN104267740ARealize precise positioning functionSimple structurePosition/direction controlNumerical controlLeveling mechanism

The invention provides an automatic leveling mechanism for a parallel transmission structure and belongs to the technical field of automatic precision adjustment. The automatic leveling mechanism aims to solve the problems that when a numerically-controlled machine tool, a numerically-controlled carving machine, a 3D printer and other devices are positioned accurately in the Z-axis direction through manual adjustment, consumed time is long, the labor intensity is high and the error of a measuring result is large in the adjusting process. A heating block is arranged in a parallel connection support. The lower end of a spray head stretches out of a spray head mounting hole in the heating block. The upper end of the spray head is fixedly connected with a spray head fixing base. The upper end of the spray head fixing base fixedly penetrates out of a through hole of a hot end assembly fixing frame. One end of the hot end assembly fixing frame is hinged to the parallel connection support. A microswitch is fixedly connected with the parallel connection support. The microswitch is located over the other end of the hot end assembly fixing frame. A gap is formed between the microswitch and the hot end assembly fixing frame. The hot end assembly fixing frame is connected with the bottom of the parallel connection support through an elastic extension mechanism. The automatic leveling mechanism is mainly applied to the numerically-controlled machine tool, the numerically-controlled carving machine, the 3D printer, a sorting system and the like.

Owner:黑龙江科大科技开发有限公司

Piano key playing force adjusting device

The invention discloses a piano key playing force adjusting device and mainly relates to the field of piano key adjusting devices. A balance weight box is arranged on each piano key, a balance weightis arranged in each balance weight box, a ball screw is arranged on each balance weight and fixedly connected with a first bevel gear, a second bevel gear is meshed to each first bevel gear, a drive shaft is arranged at each box shaft hole, a first fixed block is arranged at one end of a key frame, a first telescopic rod is arranged on the first fixed block, a chute is formed in the other end of the key frame, a second fixed block is arranged at one end of the chute, a second telescopic rod is arranged on the second fixed block and provided with a slider, a motor is arranged on the slider, anda motor key is arranged on an output shaft of the motor. The piano key playing force adjusting device has the following beneficial effects: the problem that the key playing force of the conventionalpiano cannot be adjusted wholly is solved, adjustment is convenient, short time is consumed, and the device is quite applicable to the condition that key playing force needs to be adjusted frequently.

Owner:HUNAN CITY UNIV

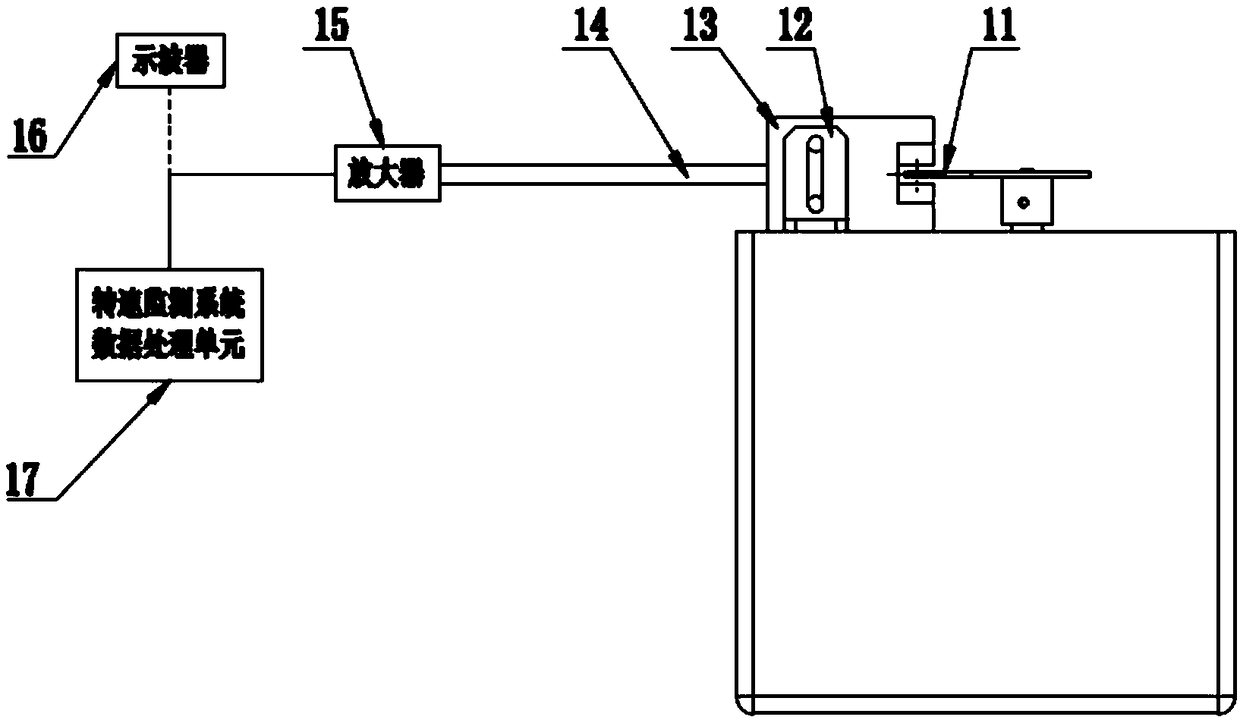

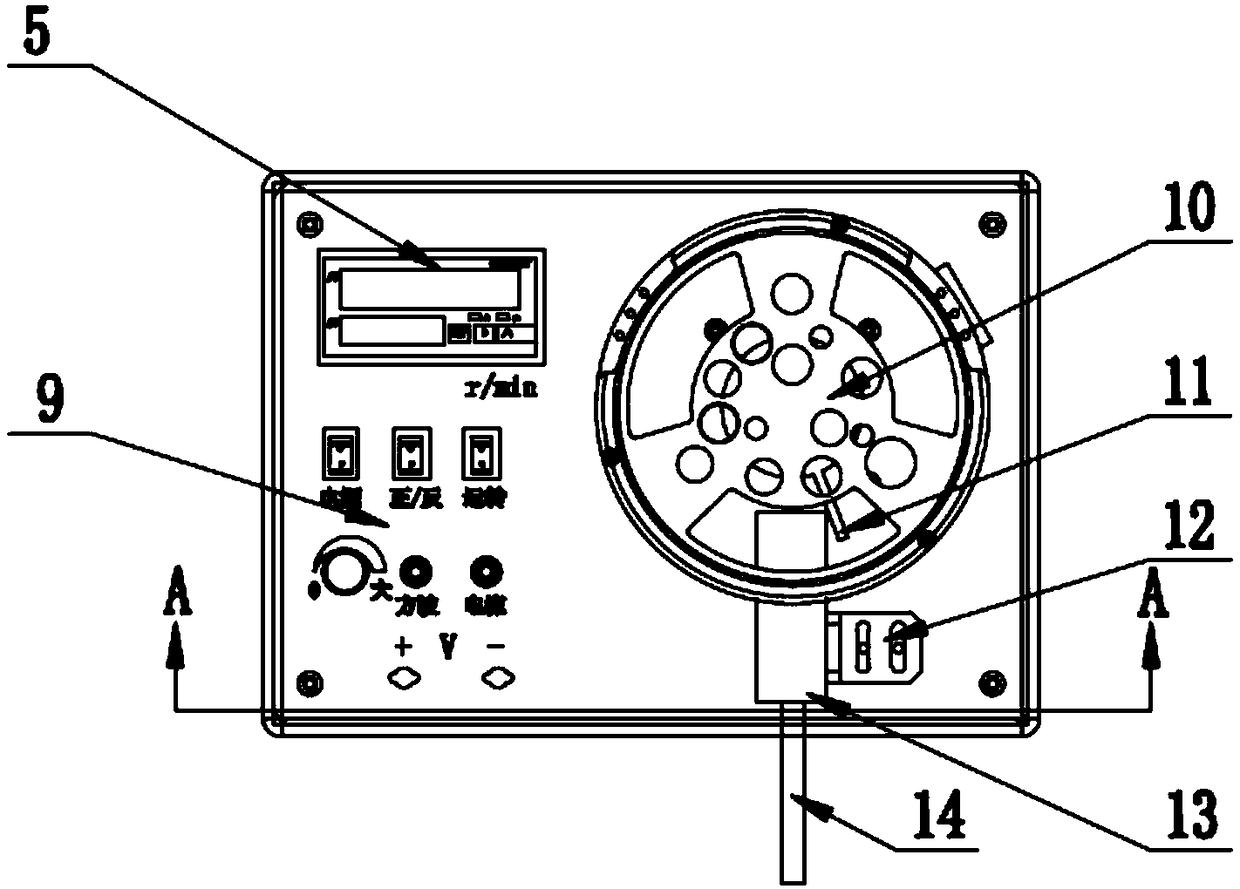

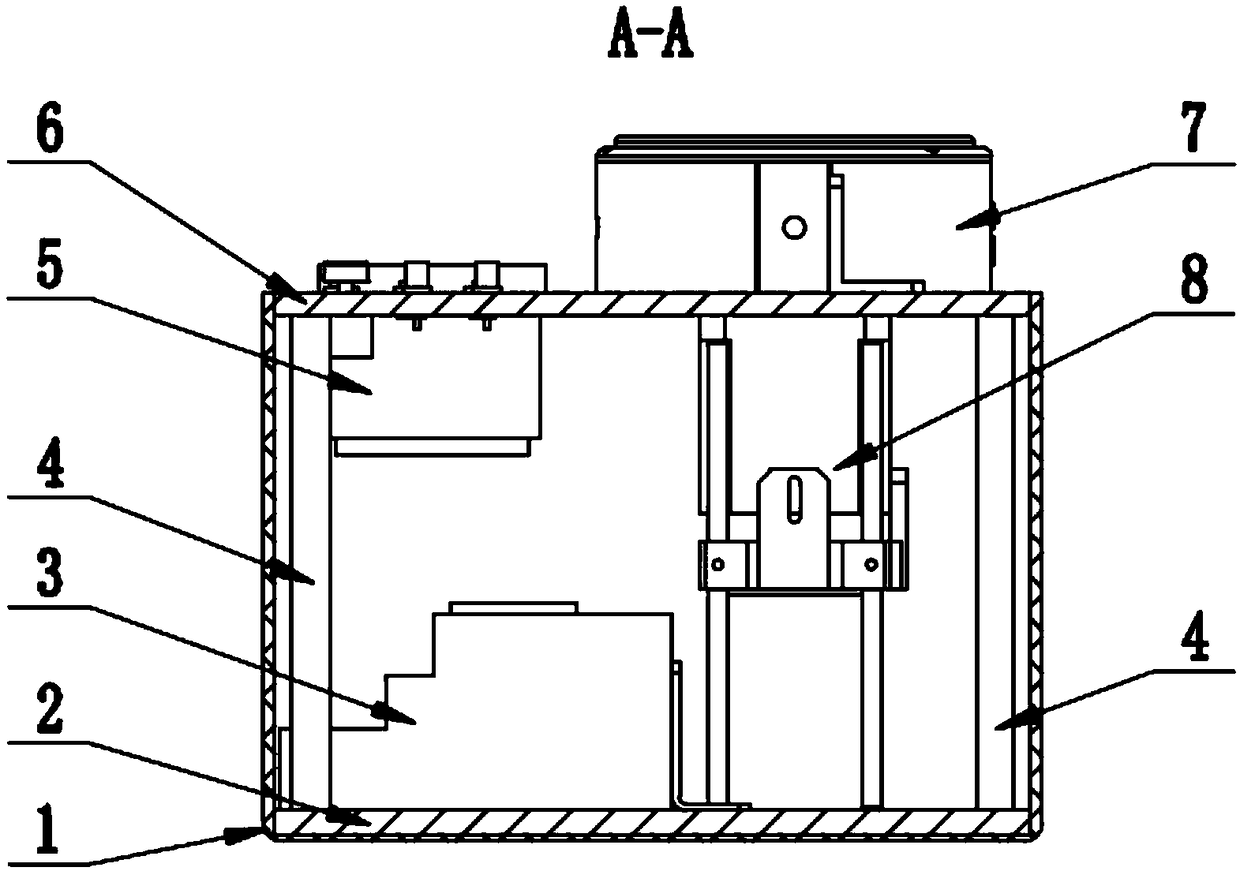

Detection calibration device of coolant pump rotating speed monitoring system and detection calibration method of detection calibration device

PendingCN108761136AResolve detectionSuppression of interfering signalsTesting/calibration of speed/acceleration/shock measurement devicesCoaxial cableAudio power amplifier

The invention discloses a detection calibration device of a coolant pump rotating speed monitoring system. The detection calibration device comprises a case, a rack arranged in the case, a motor driving module, a motor, a revolution meter, a control panel, a protection cover, a mounting bracket, a message sending tooth mounted on an output shaft of the motor, a sensor mounted on the mounting bracket, an amplifier connected with the sensor through a coaxial cable, and an oscilloscope and a coolant pump rotating speed monitoring system data processing unit that are in communication connection with a signal output end of the amplifier, wherein the motor driving module, the motor, the revolution meter, the control panel, the protection cover and the mounting bracket are mounted on the rack; the motor driving module is connected with the motor, the revolution meter and the control panel through wires; the control panel is connected with a power supply, the motor driving module and the revolution meter through wires; and during operation, the message sending tooth is driven by the output shaft of the motor to pass through the sensor. The device solves the problem that a special detectioncalibration device for the coolant pump monitoring system and a detection calibration method are unavailable at present.

Owner:仪凤机电(嘉兴)检测技术服务有限公司

Rolling mill for rectangular steel tubes

ActiveCN104384188AImprove rigiditySolve the vibrationMetal rolling stand detailsMetal rolling arrangementsStrip millEngineering

The invention discloses a rolling mill for rectangular steel tubes. The rolling mill comprises a base; the base is fixedly provided with a left rack and a right rack; a top roll, a bottom roll, a left roll and a right roll are respectively arranged on the left rack and the right rack; the rolling mill also comprises an arched adjusting bracket and a cross beam connected with the upper end of the left rack and the upper end of the right rack; U-shaped chutes are respectively formed in the left rack and the right rack; two ends of the arched adjusting bracket are respectively arranged in the U-shaped chutes, and are in vertical sliding fit with the U-shaped chutes; the middle part of the arched adjusting bracket is provided with a lifting rod in screw-thread fit with the cross beam. According to the rolling mill disclosed by the invention, by connecting the cross beam with the left rack and the right rack, the racks form a rectangular frame structure on the whole; the racks are high in rigidity, so that the problem that the existing racks vibrate during rolling can be avoided; moreover, the arched adjusting bracket is connected with the left end and the right end of the top roll, and the top roll is adjusted to rise or fall through the lifting screw rod, so that the roll is convenient to adjust, the adjustment time is short, and the work efficiency is high.

Owner:南通重矿金属新材料有限公司

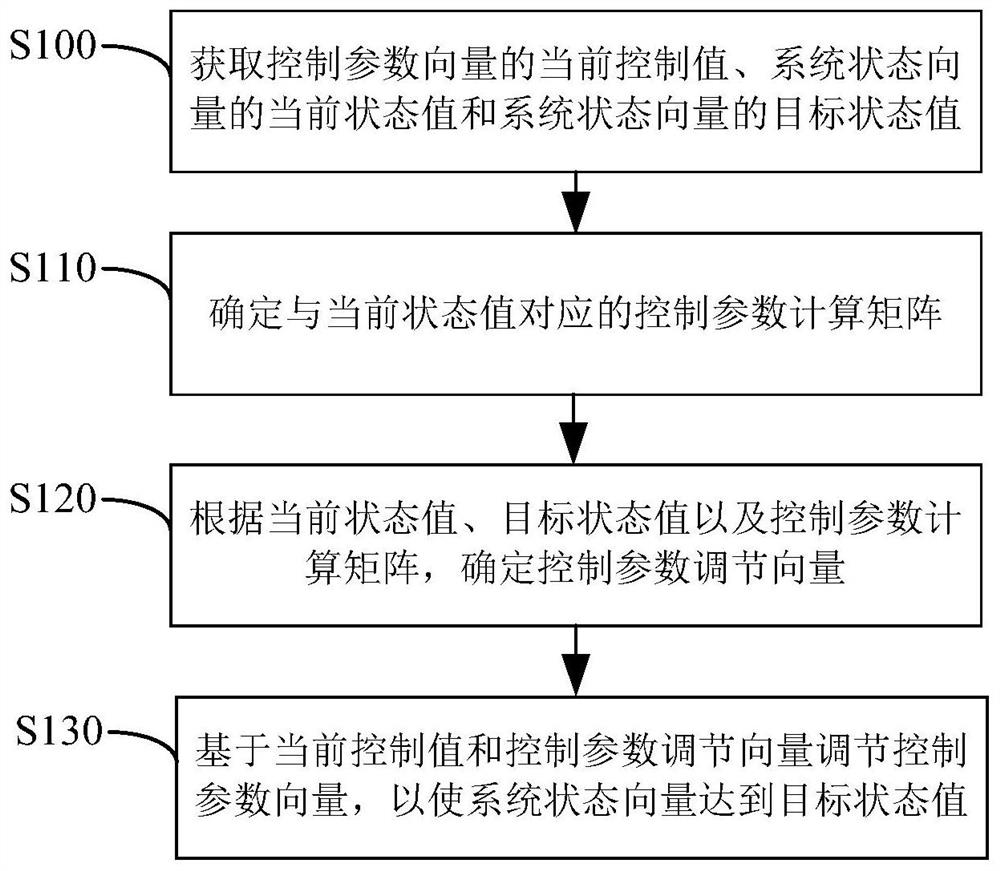

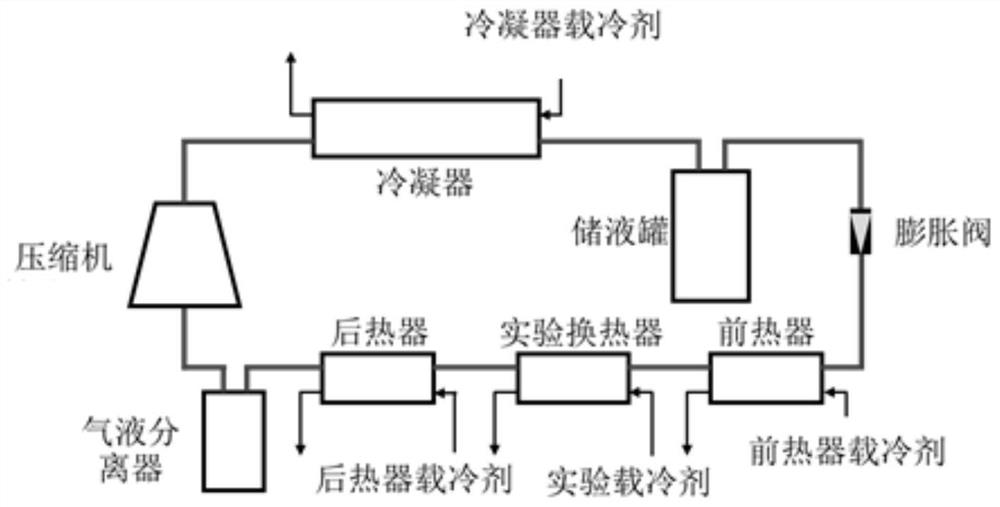

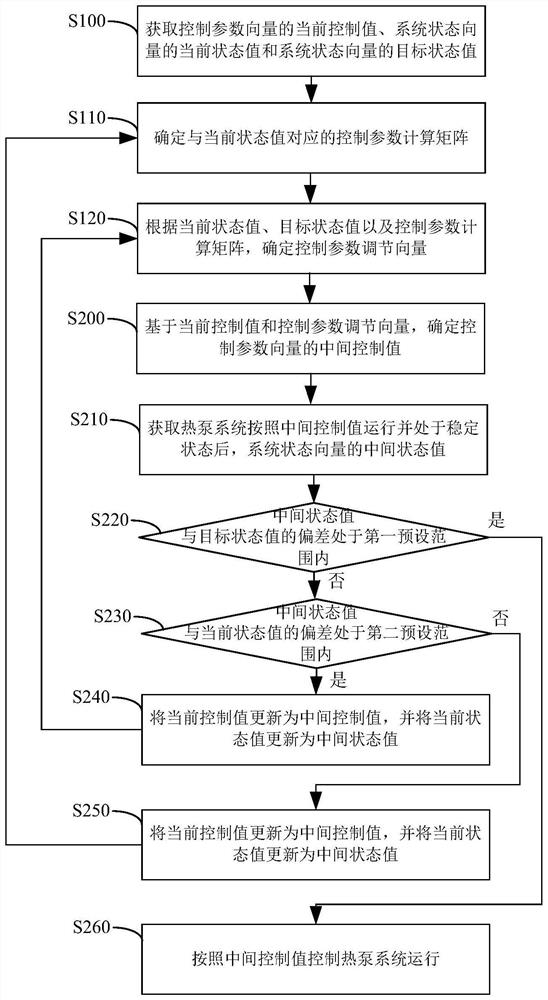

Heat pump system control method and device

ActiveCN113686066AImprove regulation efficiencyAdjustment time is shortEfficient regulation technologiesRefrigeration safety arrangementControl engineeringProcess engineering

The invention provides a heat pump system control method and device which are applied to the technical field of system control. The method comprises the steps of after obtaining a current control value of a control parameter vector, a current state value of a system state vector and a target state value, firstly determining a control parameter calculation matrix corresponding to the current state value; and determining a control parameter adjustment vector according to the current state value, the target state value and the control parameter calculation matrix, and finally adjusting the control parameter vector based on the current control value and the control parameter adjustment vector so as to enable the system state vector to reach the target state value. According to the heat pump system control method, a manual adjusting mode in the prior art can be replaced, the multiple control parameters in the heat pump system can be adjusted at the same time, and compared with the prior art, the adjusting time consumption can be effectively shortened, and the adjusting efficiency of the heat pump system can be remarkably improved.

Owner:JINGWEI HIRAIN (TIANJIN) RES&DEV CO LTD

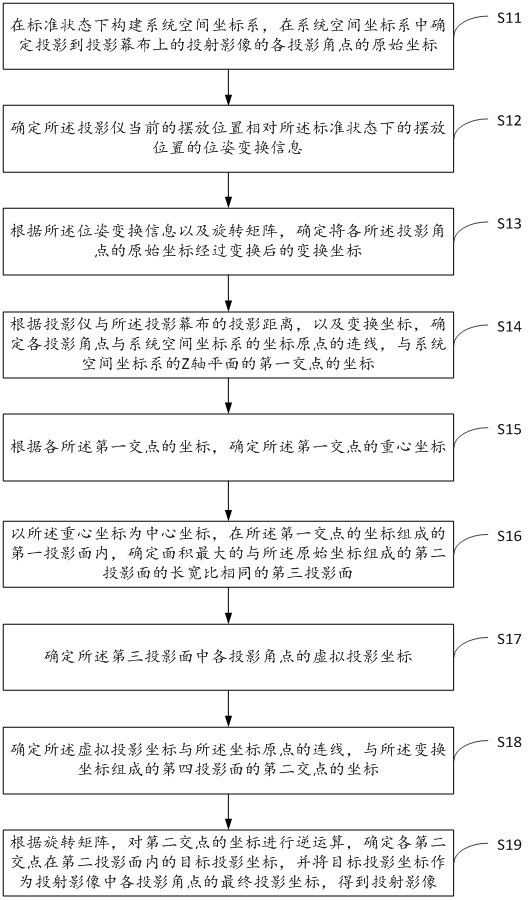

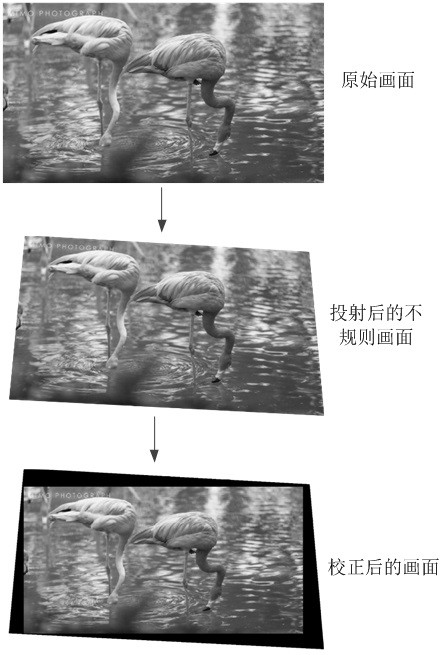

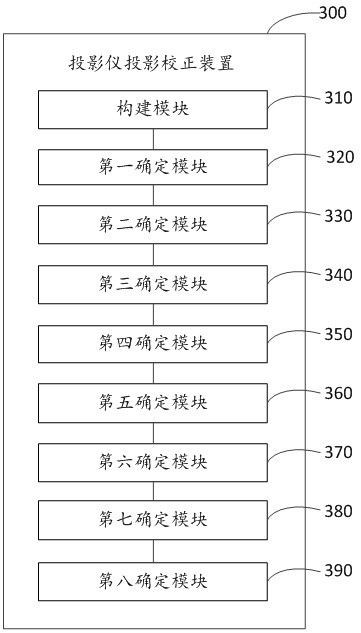

Projector projection correction method and device and projector

ActiveCN114727081AAccurate calculationReduce operational complexityPicture reproducers using projection devicesComputer graphics (images)Projection image

The invention relates to a projector projection correction method and device and a projector. Comprising the following steps: determining original coordinates of each projection angular point in a projection image in a system space coordinate system; according to the pose transformation information of the placement position of the projector relative to the standard state, determining transformation coordinates after the original coordinates of each projection angular point are transformed; according to the distance between the projector and the projection curtain and the transformation coordinate, determining the coordinate of a first intersection point of a connecting line of the projection angular point and the coordinate origin and the Z-axis plane; taking the barycentric coordinate of the first intersection point as a central coordinate, and determining a third projection plane with the largest area and the same length-width ratio as a second projection plane formed by the original coordinates in a first projection plane formed by the coordinates of the first intersection point; determining a virtual projection coordinate of each projection angular point in the third projection plane; determining coordinates of a second intersection point of a connecting line between the virtual projection coordinates and the origin of the coordinates and a fourth projection plane formed by the transformation coordinates; and carrying out image projection according to projection coordinates obtained by carrying out inverse operation on the coordinates of the second intersection point.

Owner:深圳新智联软件有限公司

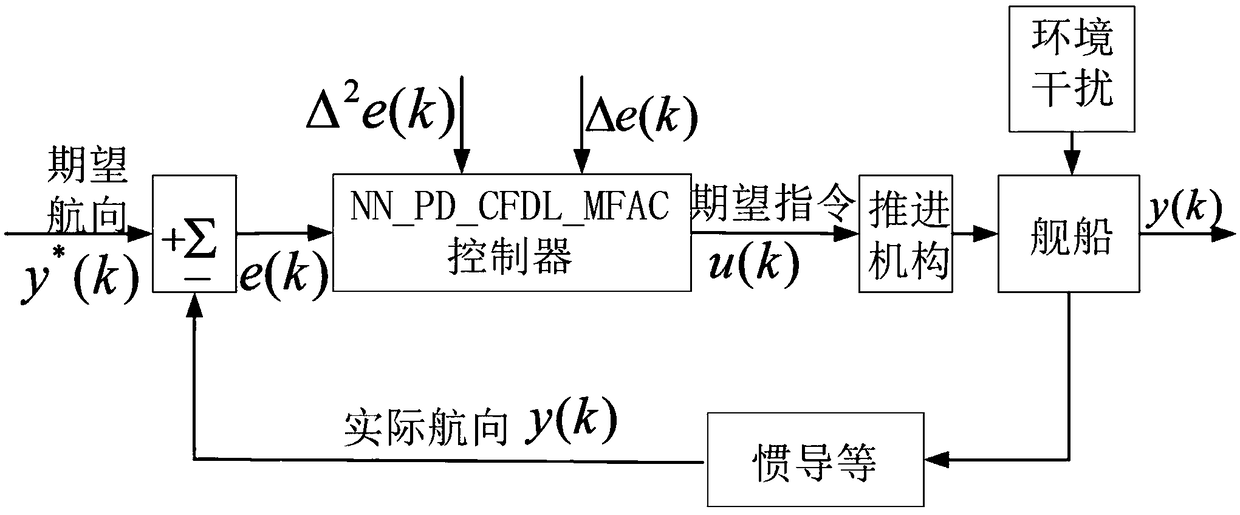

Compact format model-free adaptive course control algorithm of fusion neural network PD used for ship

ActiveCN109375637AImprove adaptabilityQuick responseAttitude controlAutomatic controlNetwork control

The invention belongs to the ship motion automatic control field and especially relates to the compact format model-free adaptive course control algorithm of a fusion neural network PD used for a ship. The algorithm comprises the following steps of based on the compact format model-free adaptive control algorithm, introducing a proportional item and a differential item to form a fusion PD type CFDL_MFAC algorithm; combining neural network control with a PD_CFDL_MFAC algorithm to provide the compact format model-free adaptive course control algorithm of fusion neural network PD; and calculatinga course deviation e(k), wherein the e(k)=y<*>(k)-y(k), and the like. Through introducing the proportional item and the differential item, the adaptability of the algorithm and the capability of resisting external uncertainty disturbance are increased.

Owner:HARBIN ENG UNIV

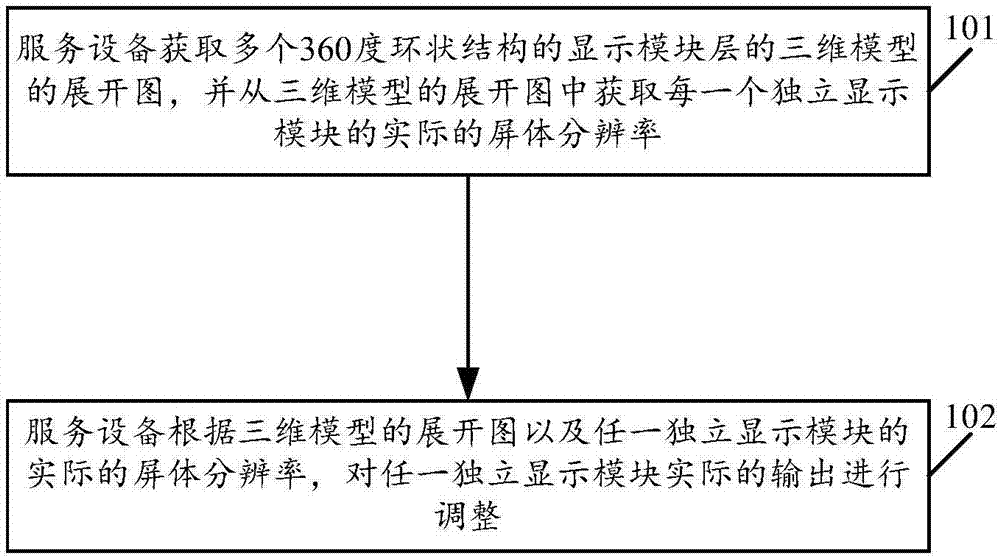

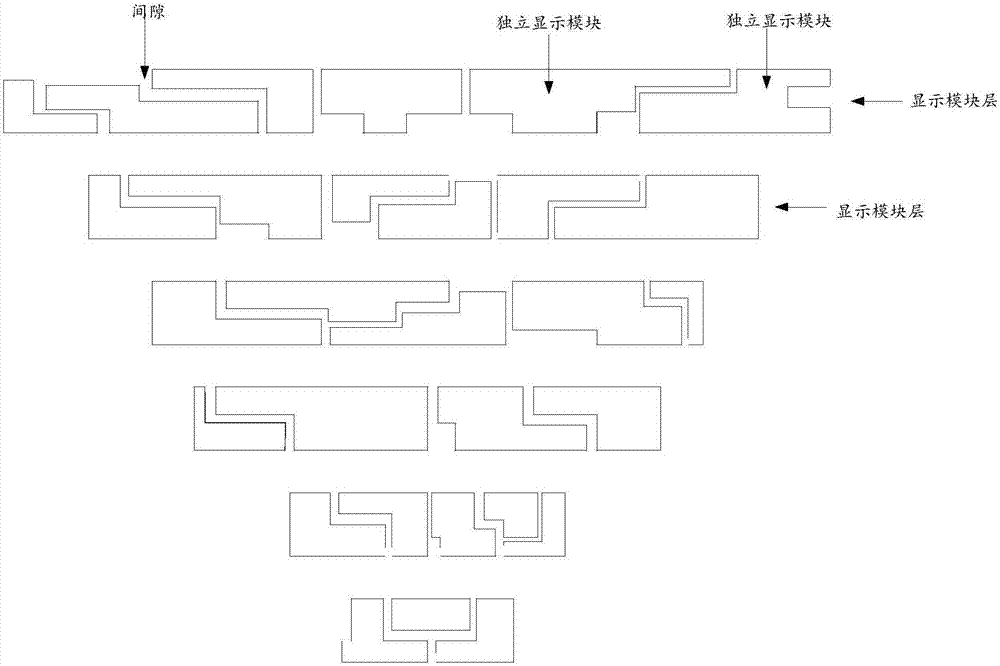

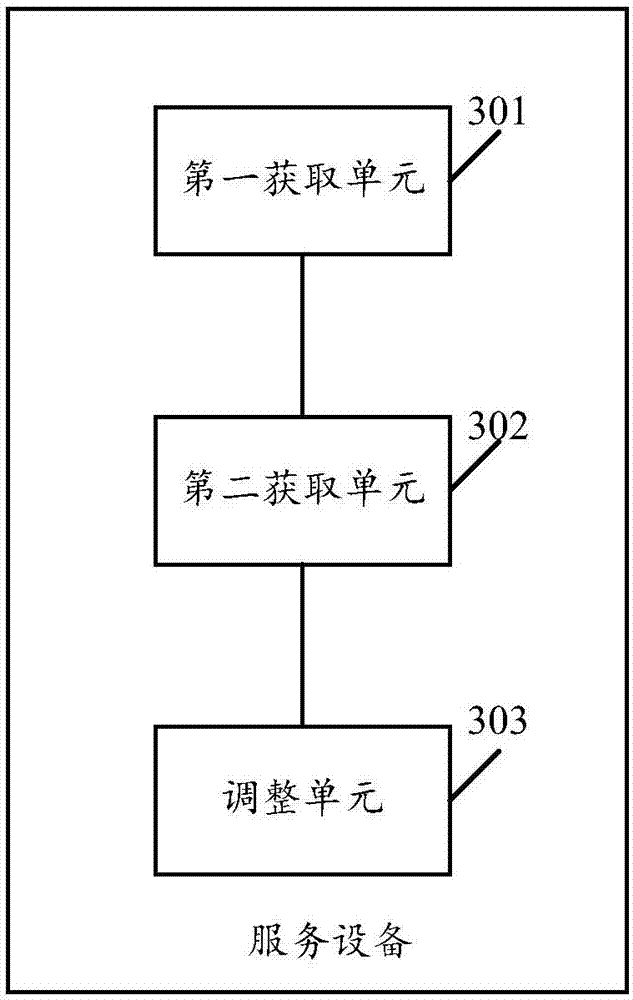

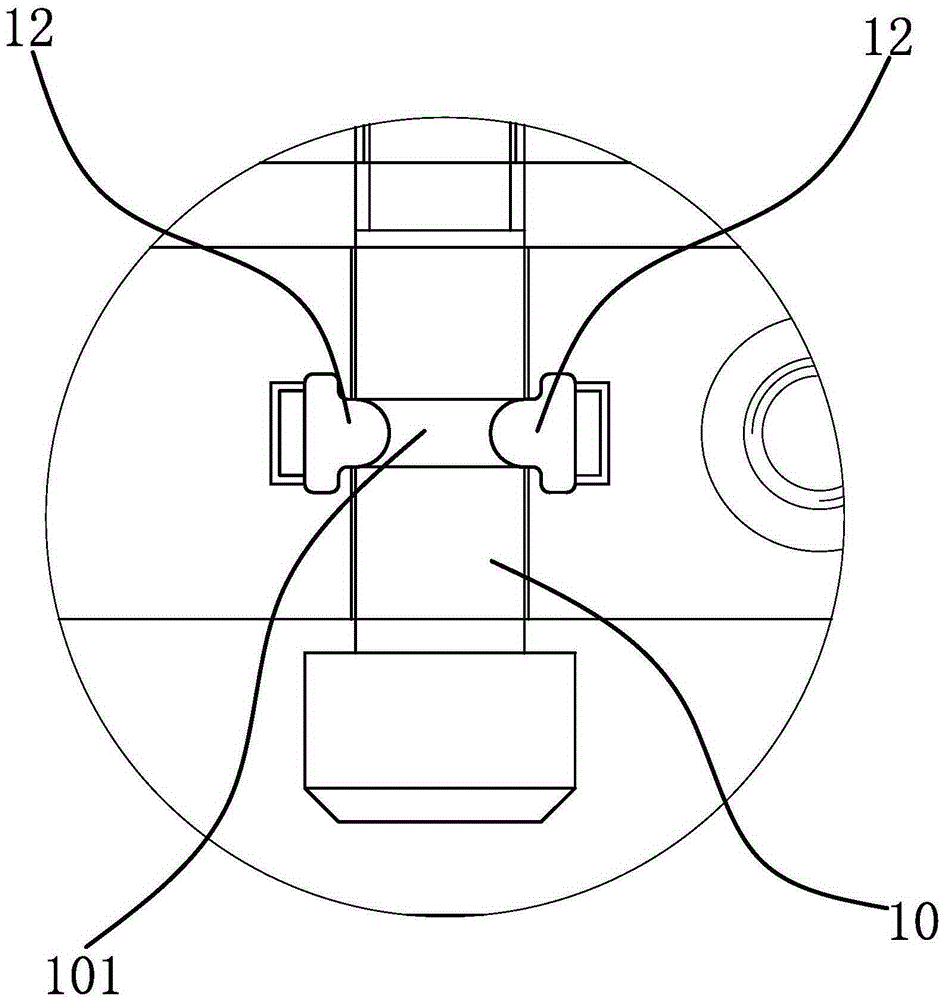

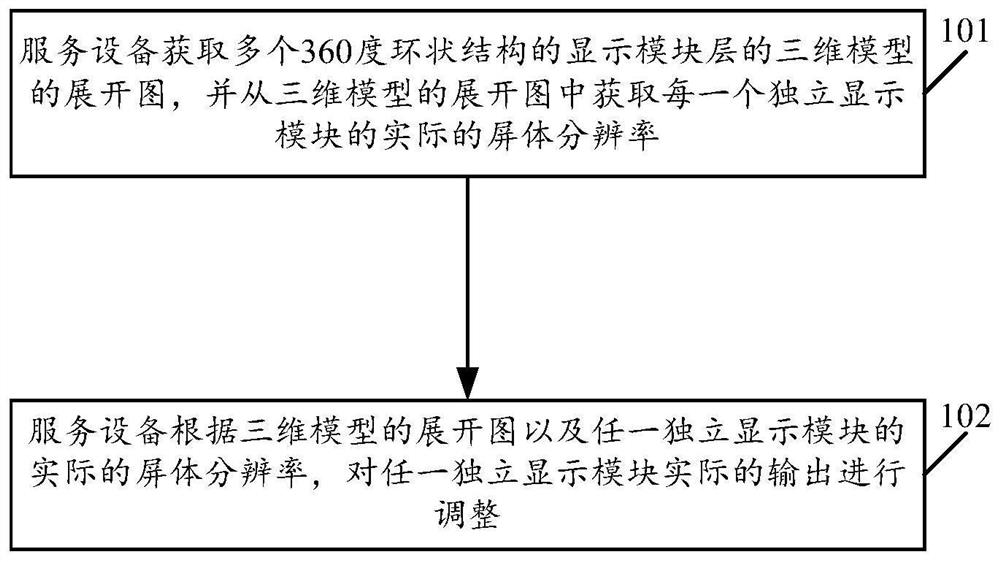

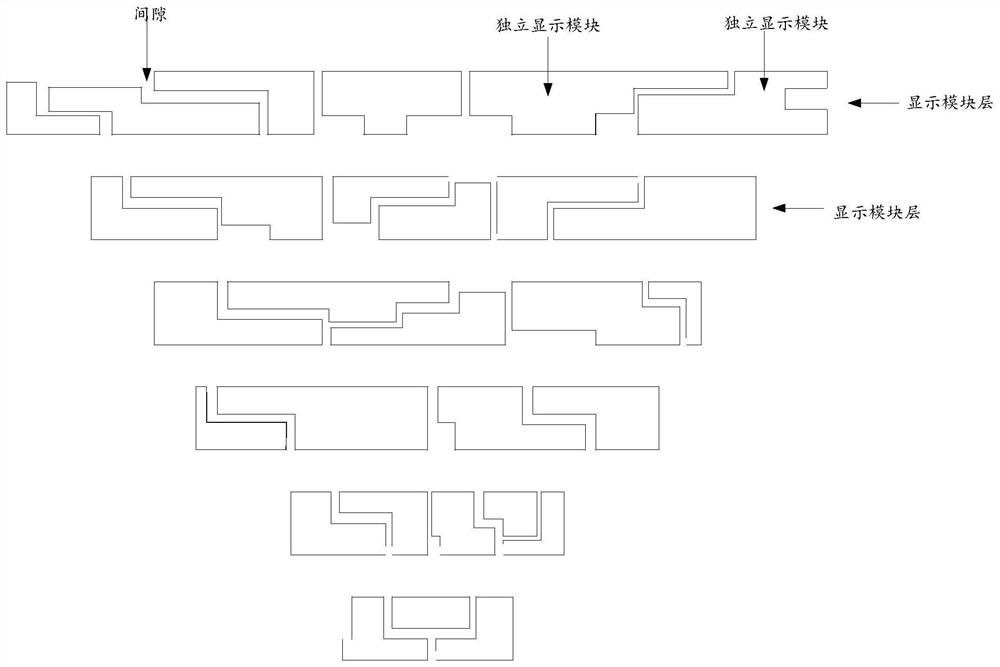

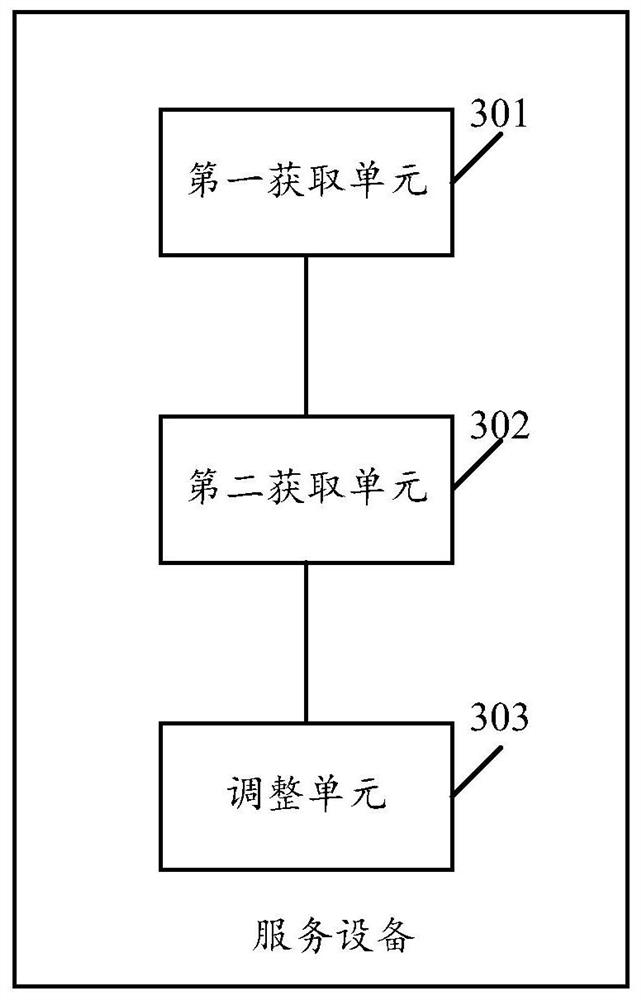

Output method for independent display modules of digital artistic landscape apparatus, and service device

ActiveCN107393012AAdjustment time is shortImprove output efficiencyTransmissionImage data processingComputer graphics (images)Computer module

The invention discloses an output method for independent display modules of a digital artistic landscape apparatus, and a service device. According to the method, the digital artistic landscape apparatus comprises a plurality of display module layers adopting 360-degree annular structures and distributed at intervals along a same vertical axis; each display module layer is divided into a plurality of independent display modules adopting deformed structures and spaced mutually; the service device establishes an independent communication connection with each independent display module; the service device obtains an expanded view of a three-dimensional model of the display module layers adopting the 360-degree annular structures, and obtains actual screen body resolution of each independent display module from the expanded view of the three-dimensional model; and according to the expanded view of the three-dimensional model and the actual screen body resolution of any independent display module, actual output of any independent display module is adjusted. By implementing the output method, the adjustment time of a relatively large quantity of the independent display modules can be shortened and the output efficiency of the independent display modules is improved.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

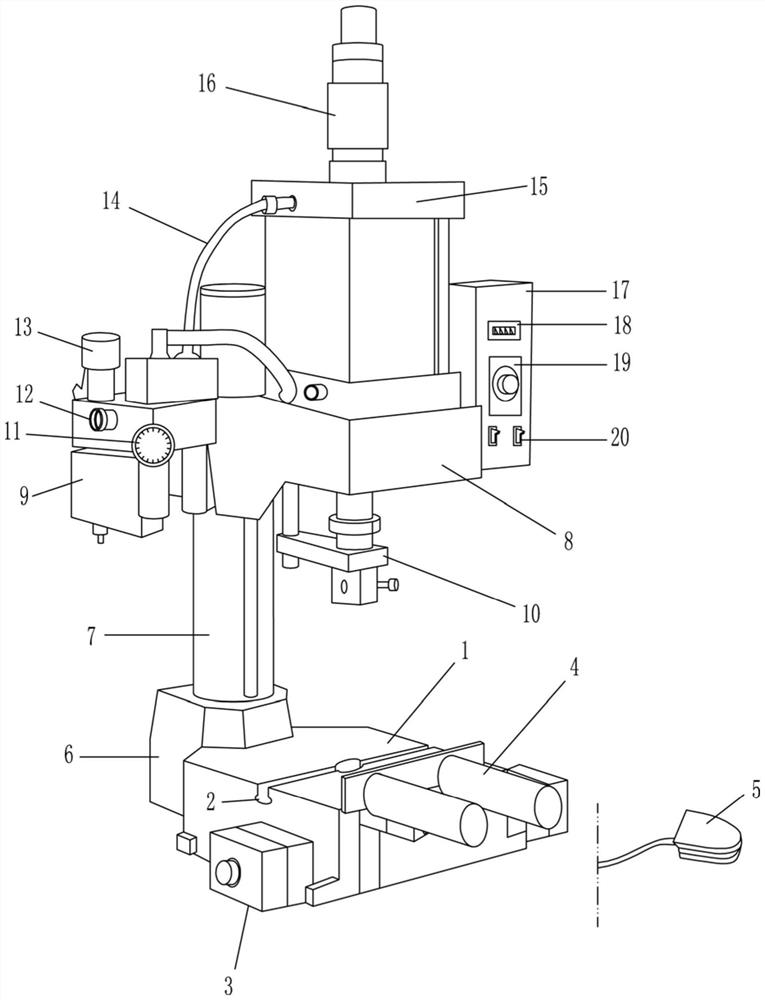

Fastening type pneumatic punching machine capable of automatically adjusting height

InactiveCN112170629AExtended service lifeQuick height adjustmentPerforating toolsShaping safety devicesAuto regulationPunching

The invention relates to the field of pneumatic punching machine equipment, in particular to a fastening type pneumatic punching machine capable of automatically adjusting height. The technical problem to be solved by the invention is to provide the fastening type pneumatic punching machine which can automatically adjusting the height to adapt to different products, meanwhile, can carry out punching stably, and is improved in service life of a foot pedal switch. The fastening type pneumatic punching machine capable of automatically adjusting the height comprises a workbench, a moving groove, control switches, fastening assemblies, a pedal control assembly, a height adjusting assembly, a mounting frame assembly, buffer equipment, a punching connecting frame, a timer, a switch set and the like, wherein a moving groove for guiding a punching part to move is formed in the top surface of the workbench; the supporting base is fixedly connected to the rear wall of the workbench; the two control switches are fixedly connected to two side walls of the workbench in sequence; and the fastening assemblies are fixedly connected to the front wall of the workbench. According to the fastening typepneumatic punching machine, the effects that the height of the punching machine can be conveniently and automatically adjusted to adapt to the different products, meanwhile, punching can be carried out stably, and the service life of the foot pedal switch can be prolonged are achieved.

Owner:邱煌庆

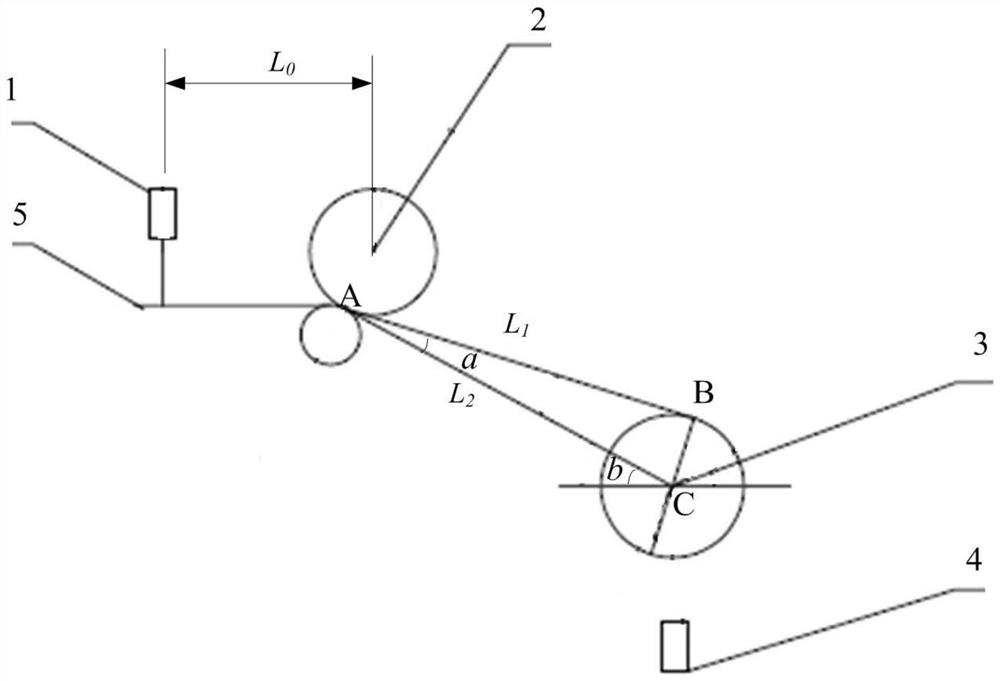

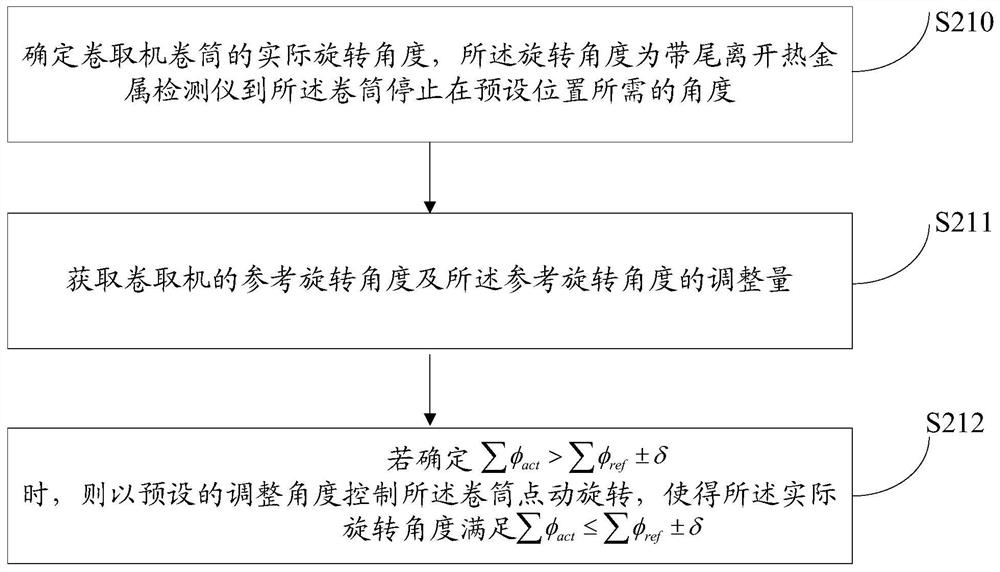

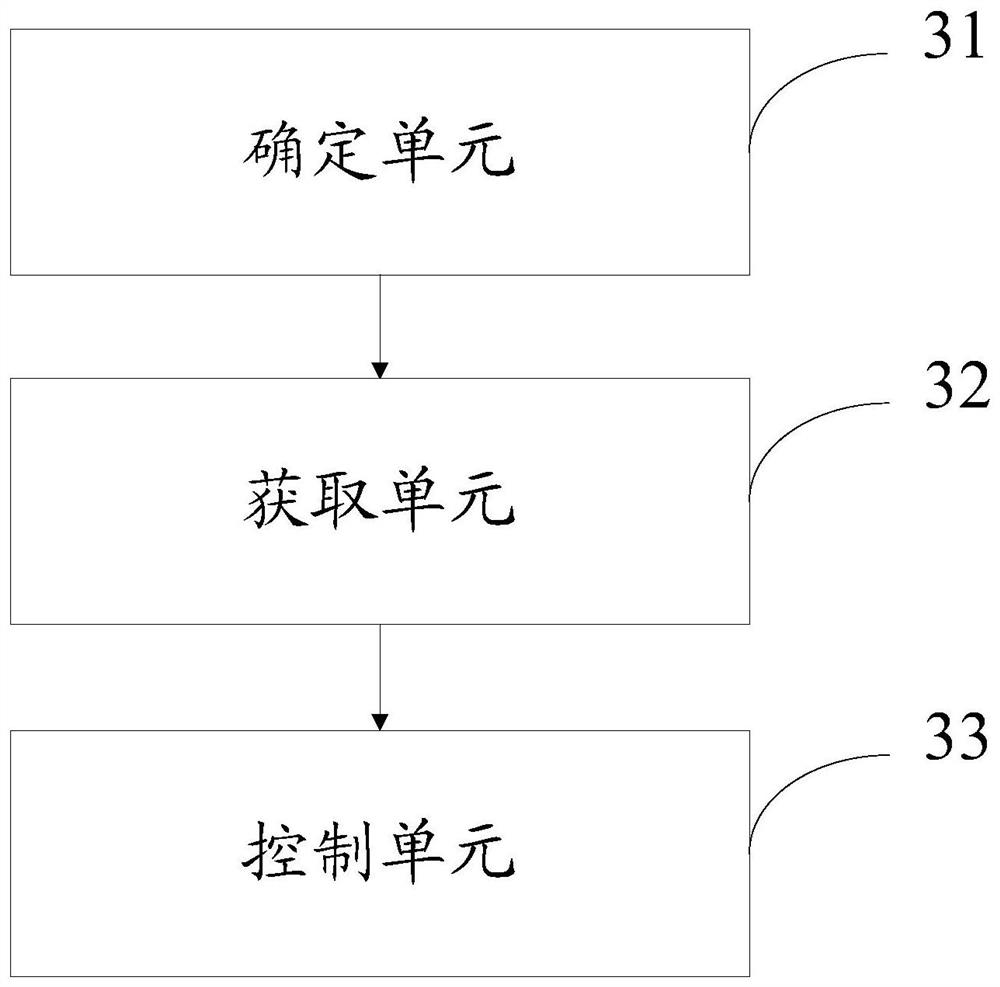

Coiling control method and device, medium and equipment

ActiveCN113617877AHigh positioning accuracyImprove coiling control precisionMetal working apparatusEngineeringMachine

The invention provides a coiling control method and device, a medium and equipment. The method comprises the steps of determining an actual rotation angle of a coiling block of a coiling machine, wherein the rotation angle is an angle required when a strip tail leaves a hot metal detector and the coiling block stops at a preset position; obtaining a reference rotation angle of the coiling block and an adjustment amount of the reference rotation angle; and controlling the coiling block to rotate in an inching mode at a preset adjusting angle if it is determined that sigma phi act is larger than sigma phi ref + / -delta, so that the actual rotating angle meets the condition that sigma phi act is smaller than or equal to sigma phi ref + / -delta, wherein sigma phi act is the actual rotation angle, sigma phi ref is the reference rotation angle, and delta is the calibration adjustment amount of the reference rotation angle. Thus, by determining the actual rotation angle and the reference rotation angle of the coiling block, when the actual rotation angle cannot enable a strip coil to stop in the optimal area, the coiling block is controlled to rotate in the inching mode according to the preset adjustment angle, so that the actual angle meets the condition that sigma phi act is smaller than or equal to sigma phi ref + / -delta, the coiling control precision is improved, the positioning precision of the tail of strip steel is improved, manual participation is not needed, adjustment time consumption is reduced, and the production efficiency is improved.

Owner:武汉钢铁有限公司

A Model-Free Adaptive Heading Control Algorithm of Integral-separated pi-type Compact Format for Ships

ActiveCN109144066BConvergent stabilityQuick responseControllers with particular characteristicsPosition/course control in two dimensionsAlgorithmClassical mechanics

Owner:HARBIN ENG UNIV

Automatic centering device of electro-spindle reliability test bench based on dragging

ActiveCN109489964BShort integrityIntegrity guaranteedMachine part testingAutomatic controlTest bench

The invention discloses an automatic centering device for an electric spindle reliability test bed based on dragging and loading. In order to overcome the problem of being unable to monitor the generation of singular data in time, eliminating and adjusting the centering of the test bed is time-consuming and laborious, the device includes a main shaft position adjustment part, The detection part and the monitoring and automatic control part; the detection part includes the support device, the feeding device and the detection device; the main shaft position adjustment part is installed in the middle of the horizontal iron through No. 1 to No. 4 static pressure slides: No. 1 and No. 2 static pressure The pressure sliding table is installed on the left side of the horizontal iron, and the No. 3 and No. 4 static pressure sliding tables are installed on the right side of the horizontal iron; the detection part is installed in the middle of the horizontal iron through the No. 1 and No. 2 support bases, and the supporting device is located on the main shaft On the front and rear sides of the position adjustment part, the feed device is installed on the support device; the No. 1 and No. 2 laser alignment instruments in the detection device are fixed on the fixed plate in the feed device; the monitoring and automatic control part and the spindle position adjustment part , Detection part of the wire connection.

Owner:JILIN UNIV

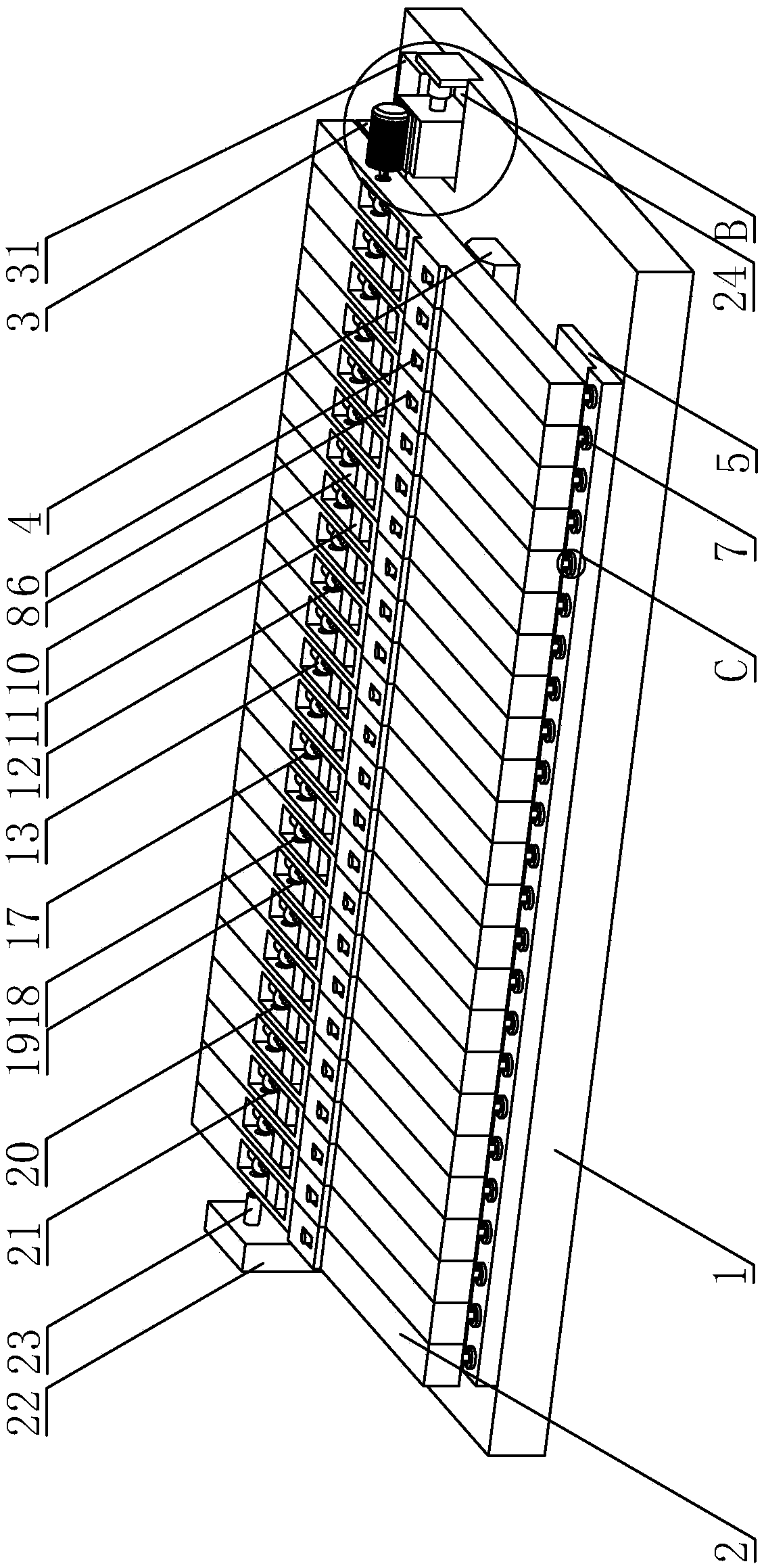

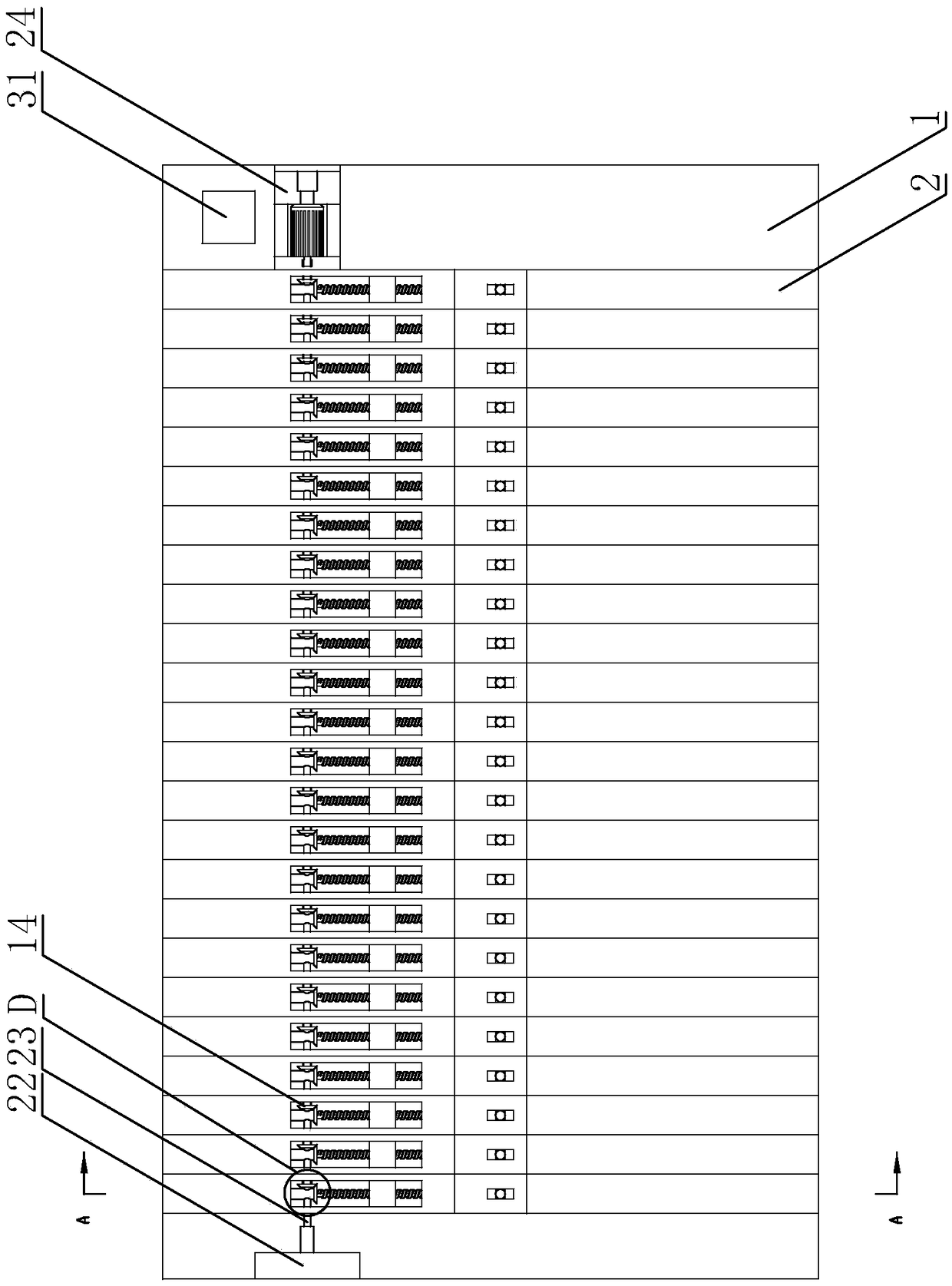

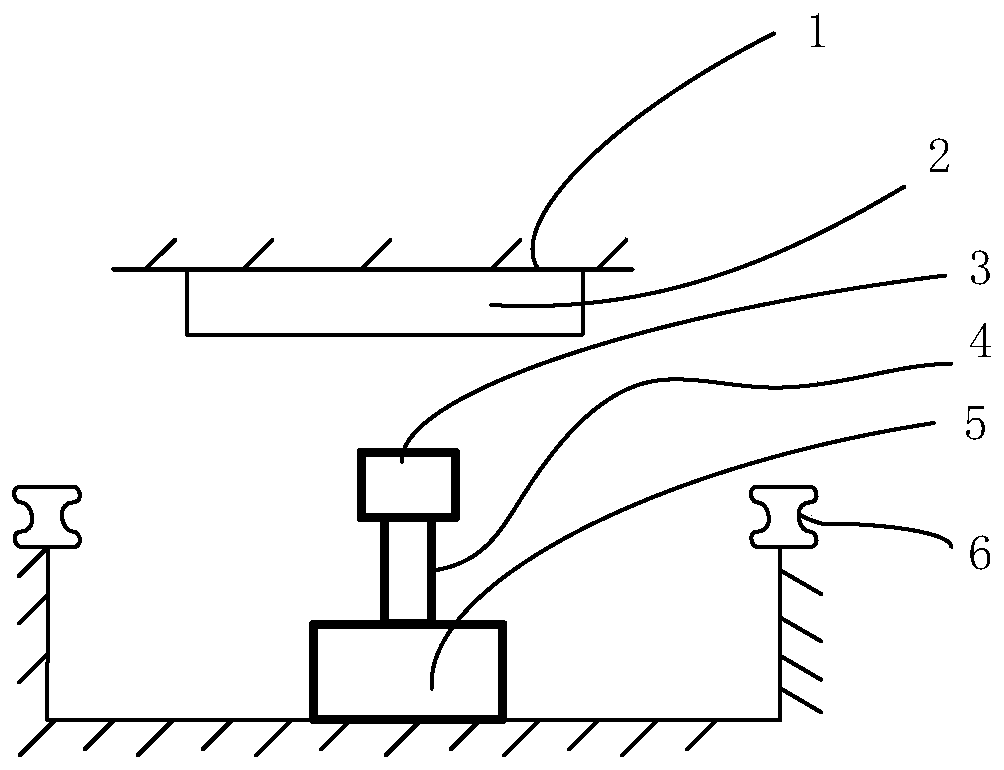

Train positioning system static testing device and static testing method

PendingCN110040156AHigh adjustment accuracyShort adjustment timeRailway signalling and safetyStatic testingTest fixture

The invention discloses a train positioning system static testing device. The train positioning system static testing device comprises an antenna mounting plane, a track, an antenna, a beacon positionmeasuring control unit, a beacon vertical position adjusting unit and a beacon plane position adjusting unit, wherein a track horizon is arranged on the track; the beacon position measuring control unit carries a beacon, is used for detecting position data of the beacon relative to the antenna, identifying a current position of the beacon according to the position data, planning a beacon moving track according to the current position and a target position and outputting a vertical moving instruction or a plane moving instruction according to the beacon moving track; the beacon vertical position adjusting unit is used for controlling the beacon position measuring control unit to move in the vertical direction according to the vertical moving instruction; and the beacon plane position adjusting unit moves on the track horizon in the horizontal direction according to the plane moving instruction. The invention further discloses a static testing method based on the train positioning system static testing device. Problems of poor manual adjusting accuracy, long adjusting time consumption and low efficiency are solved.

Owner:SHANGHAI ELECTRIC THALES TRANSPORTATION AUTOMATION SYST CO LTD

Parallel transmission structure automatic leveling mechanism

ActiveCN104267740BRealize precise positioning functionSimple structurePosition/direction controlNumerical controlLeveling mechanism

The invention provides an automatic leveling mechanism for a parallel transmission structure and belongs to the technical field of automatic precision adjustment. The automatic leveling mechanism aims to solve the problems that when a numerically-controlled machine tool, a numerically-controlled carving machine, a 3D printer and other devices are positioned accurately in the Z-axis direction through manual adjustment, consumed time is long, the labor intensity is high and the error of a measuring result is large in the adjusting process. A heating block is arranged in a parallel connection support. The lower end of a spray head stretches out of a spray head mounting hole in the heating block. The upper end of the spray head is fixedly connected with a spray head fixing base. The upper end of the spray head fixing base fixedly penetrates out of a through hole of a hot end assembly fixing frame. One end of the hot end assembly fixing frame is hinged to the parallel connection support. A microswitch is fixedly connected with the parallel connection support. The microswitch is located over the other end of the hot end assembly fixing frame. A gap is formed between the microswitch and the hot end assembly fixing frame. The hot end assembly fixing frame is connected with the bottom of the parallel connection support through an elastic extension mechanism. The automatic leveling mechanism is mainly applied to the numerically-controlled machine tool, the numerically-controlled carving machine, the 3D printer, a sorting system and the like.

Owner:黑龙江科大科技开发有限公司

Seal paper receiving box of soft box packing machine

PendingCN111591540ALow costAdjustment time is shortLabelling machinesIndustrial engineeringWall plate

The invention relates to a seal paper receiving box of a soft box packaging machine. The seal paper receiving box comprises a supporting wallboard, a seal accelerating wheel, a seal paper receiving box support, a seal conveying wheel, a seal paper receiving box, a side positioning block and a bottom positioning block; the seal accelerating wheel, the seal paper receiving box support and the seal conveying wheel are all installed on the supporting wall plate; the seal paper receiving box is mounted on the seal paper receiving box support; and the side positioning block is installed on the sideof the seal paper receiving box, and the bottom positioning block is installed at the bottom of the seal paper receiving box. According to the technical scheme, the seal paper receiving box positioning blocks are decomposed, when the seal positioning blocks are adjusted, the positioning blocks do not interfere with one another, the adjusting time consumption is short, the equipment operation efficiency is improved, the adjusting difficulty and the manual labor intensity are reduced, besides, when any positioning block is damaged, the positioning block can be independently replaced, the whole seal paper receiving box does not need to be replaced, and the cost of spare and accessory parts is reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

A compact model-free adaptive heading control algorithm based on fused neural network pd for ships

Owner:HARBIN ENG UNIV

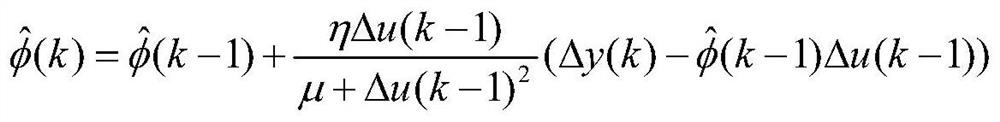

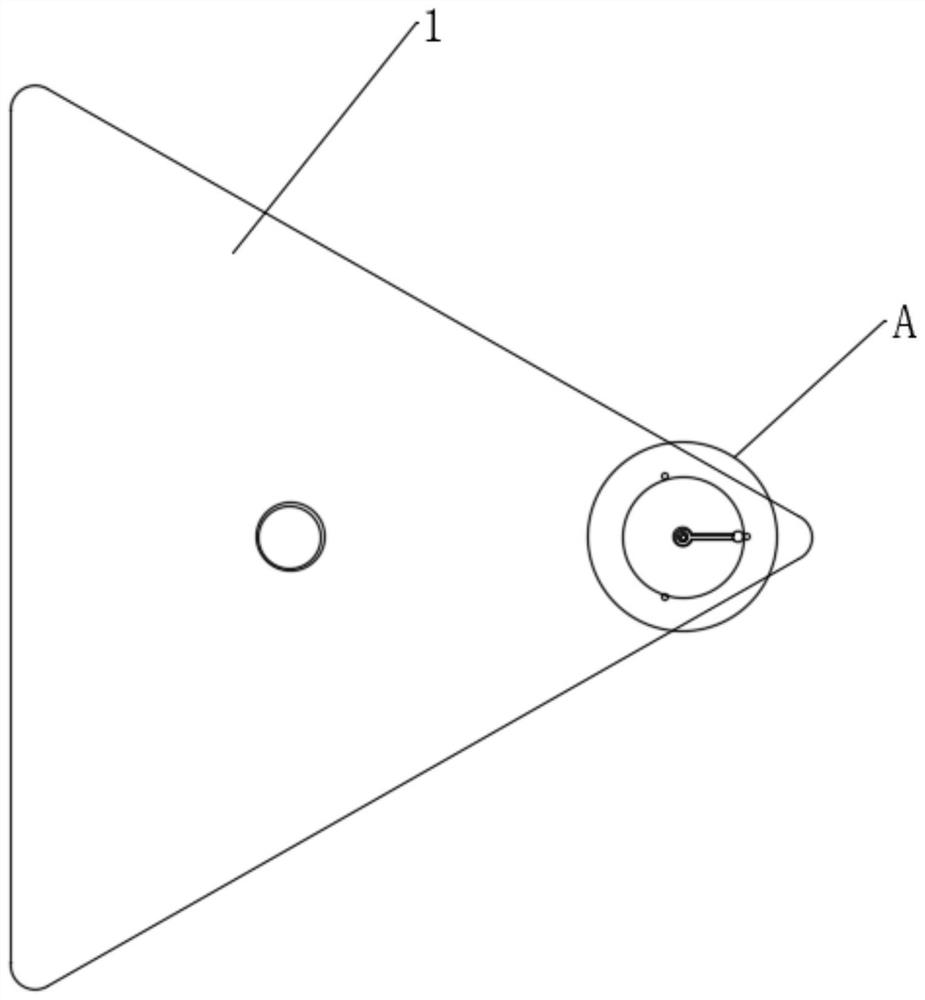

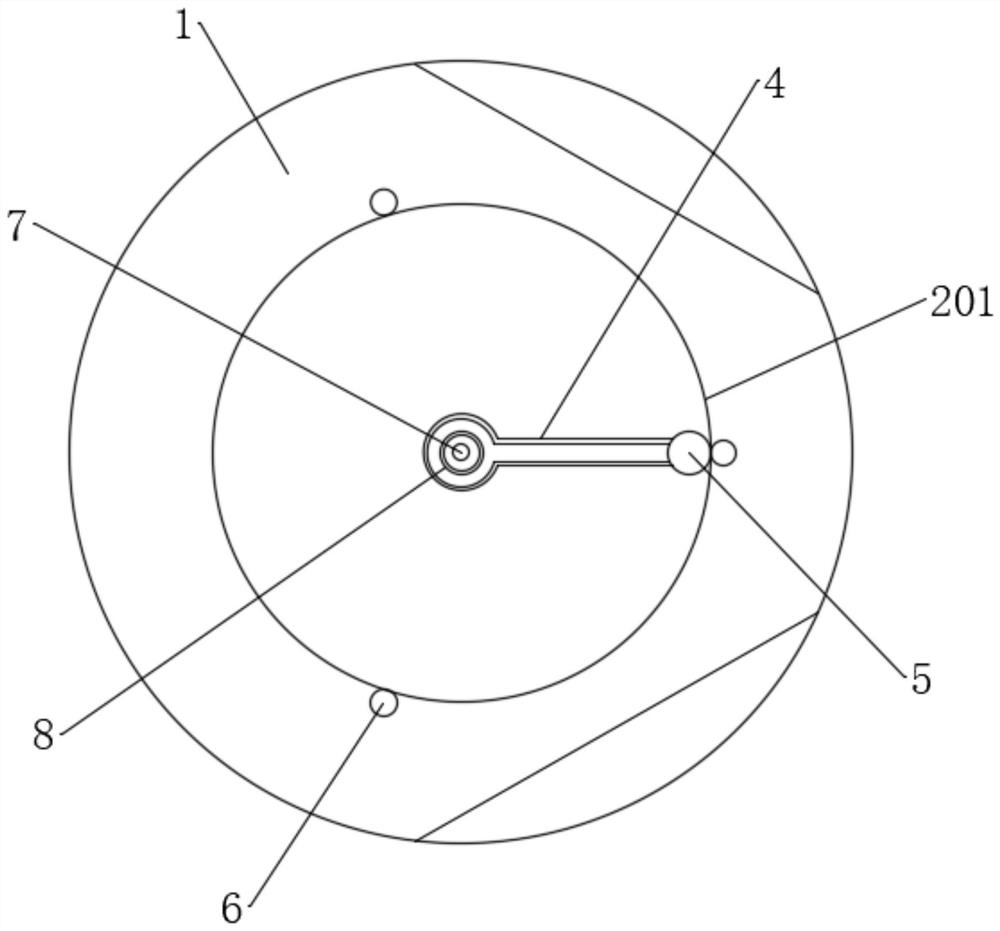

A pointer homing type automatic adjustment and measurement tripod

ActiveCN111595370BAchieve rough levelingAdjustment time is shortMeasurement apparatus componentsStands/trestlesSimulationCentral pressure

The invention discloses a pointer homing type automatic adjustment and measurement tripod, belonging to the technical field of measurement, which can realize rapid automatic adjustment of the levelness of the tripod, and jointly guide the lifting adjustment of self-elevating outriggers through a triangular pressure contact and a central pressure contact Specifically, the technician first controls one of the self-lifting outriggers to rise to a suitable height in advance, and then automatically adjusts the other self-elevating outrigger to the same height, and the self-moving indicator ball driven by the self-rotation limit shift pointer stays to press the last self-lifting The triangle pressure contact corresponding to the outrigger shall prevail, and then the last self-lifting outrigger is automatically adjusted until the self-moving indicator ball moves precisely along the self-rotation limit movement pointer to the center pressure contact, so as to realize the roughness of the horizontal plane and greatly shorten the adjustment time. Improve the measurement efficiency, and at the same time, within the allowable range of measurement error, by setting a weak angle control loop to meet the offset of the self-moving indicator ball within a certain range, the measurement accuracy can be effectively improved within the tolerance range.

Owner:林红英

A Punch Position Adjustment Mechanism in Continuous Drawing Die

Owner:松渤电器(上海)有限公司

Independent display module output method and service equipment of digital art landscape device

ActiveCN107393012BAdjustment time is shortImprove output efficiencyTransmissionImage data processingComputer graphics (images)Image resolution

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

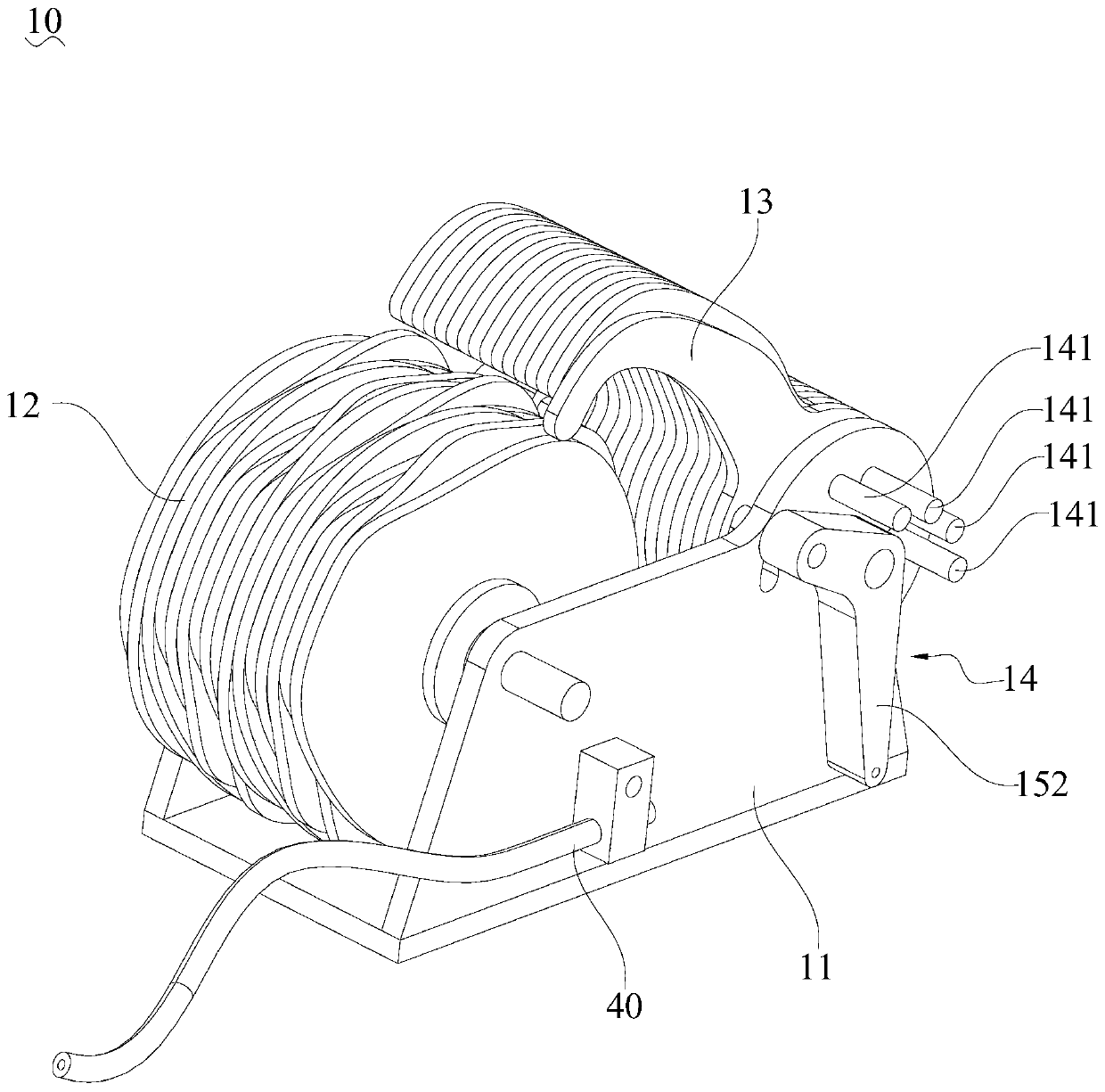

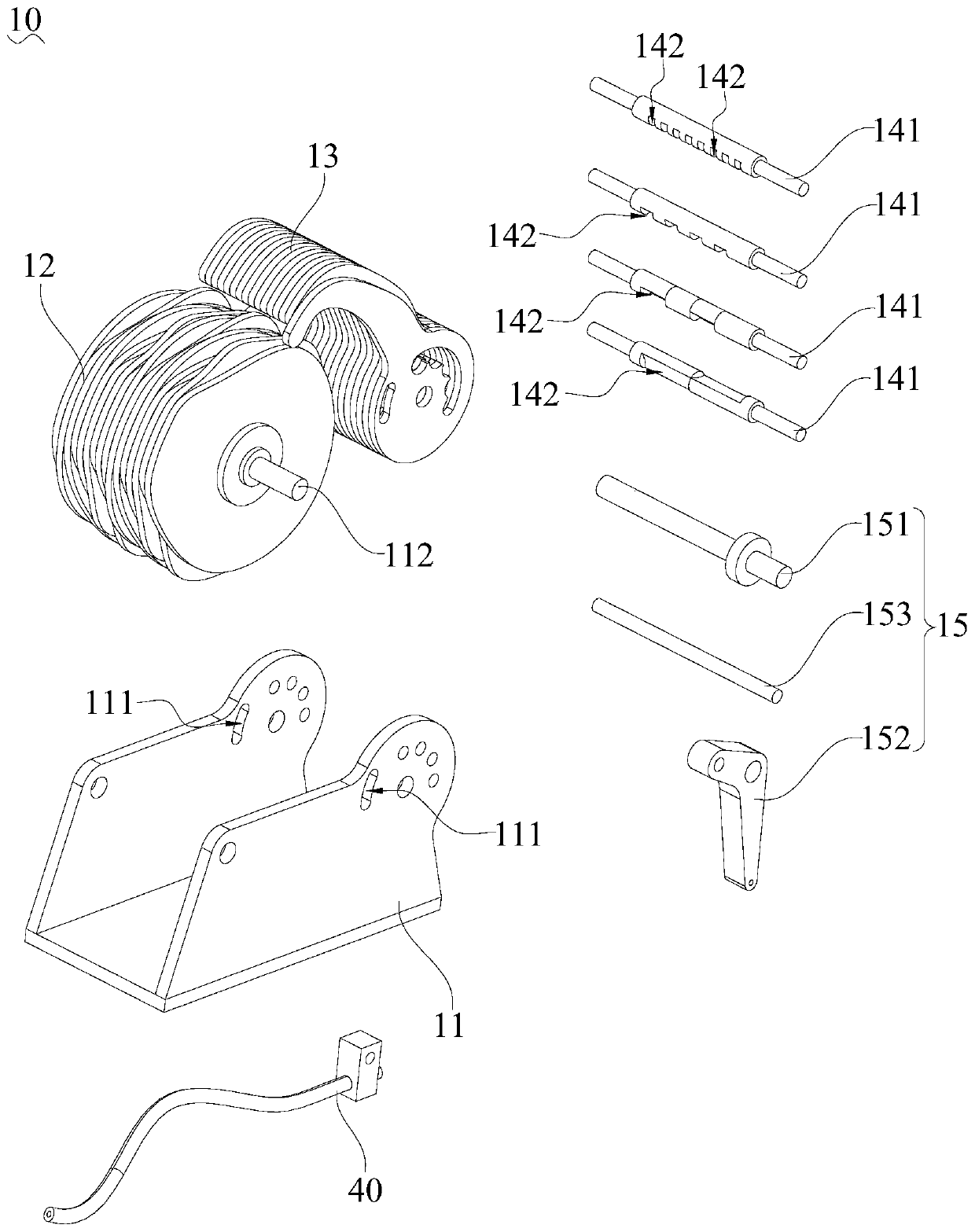

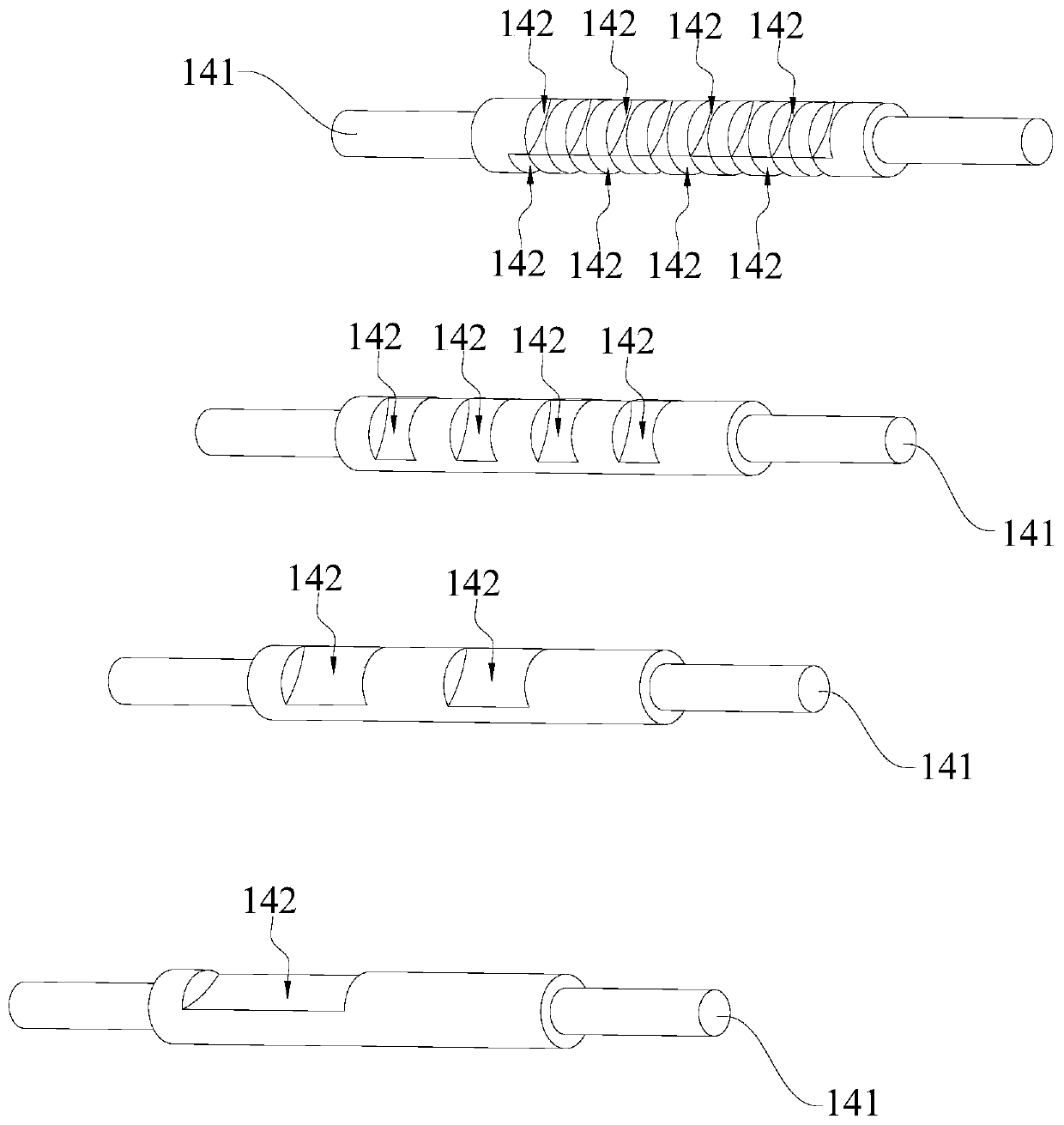

Cam driving device and automatic equipment

The invention belongs to the technical field of driving equipment, and in particular to a cam driving device and automatic equipment. The cam driving device comprises a support frame body, a pluralityof cams with different appearances and contours, a plurality of swinging pieces and a switching transmission mechanism, the cams are arranged on the first installation side of the supporting frame body and driven by a driving mechanism to rotate, the swinging pieces are arranged on the second installation side of the supporting frame body, and the switching transmission mechanism is in transmission connection with the swinging pieces and used for driving the designated swinging piece to abut against the corresponding cam so that the cam drives the designated swinging piece to rotate. Therefore, the transmission mechanism is switched to drive the different swinging pieces to swing along with rotation of the corresponding cams, so that different swinging rules of the swinging pieces of thecam driving device are output, the cams are cooperated with the swinging pieces to realize movement, the cam does not need to be replaced and debugged, then the implementation and operation cost is remarkably reduced, the debugging time is remarkably shortened, and the operation efficiency is improved.

Owner:SHENZHEN UNIV

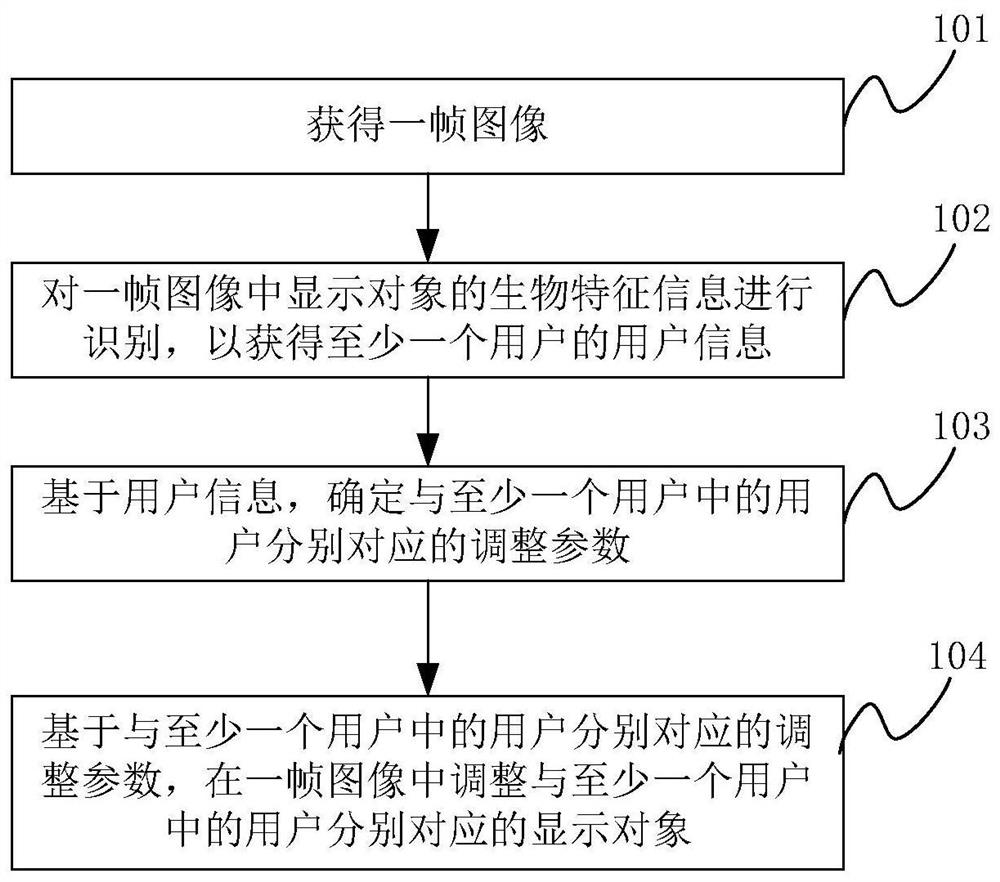

Image processing method, device and electronic equipment

ActiveCN110248104BImproving Imaging EfficiencyAdjustment time is shortTelevision system detailsColor television detailsImaging processingComputer graphics (images)

Owner:LENOVO (BEIJING) LTD

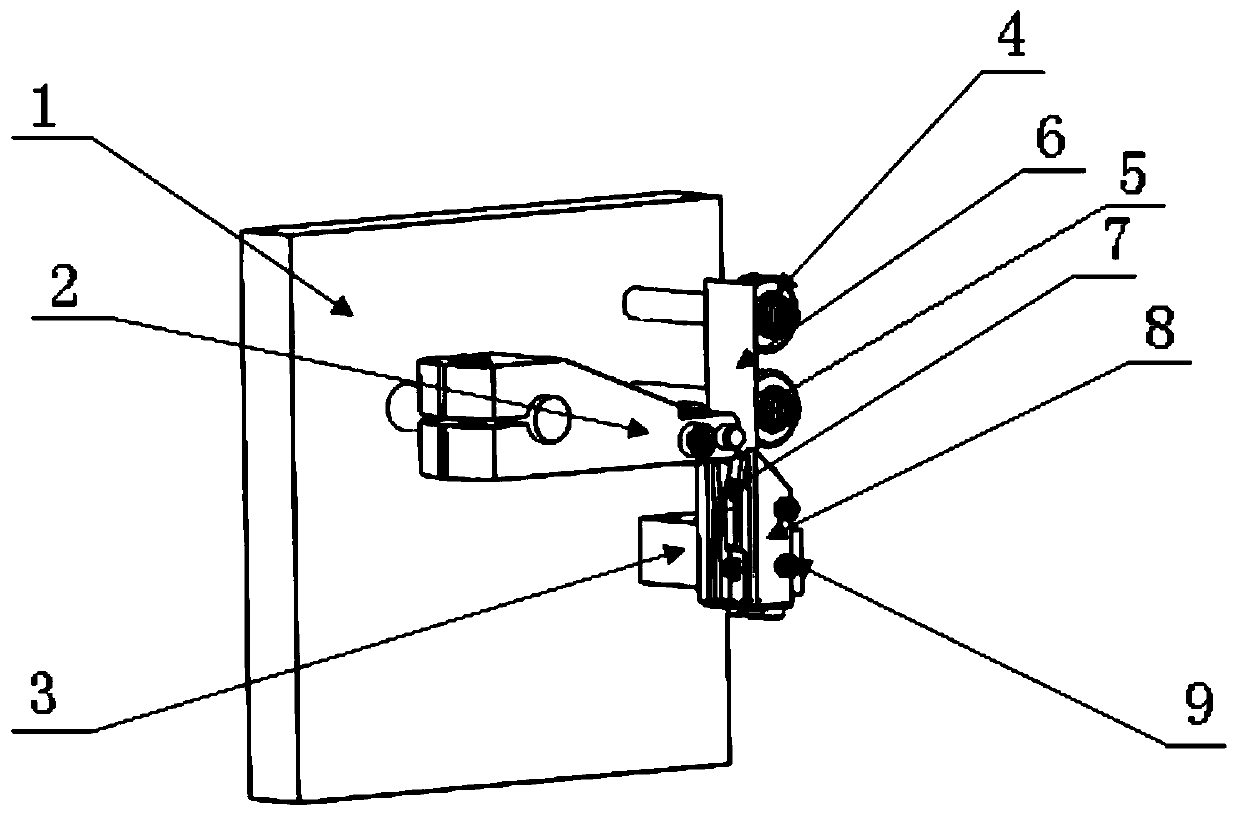

Portable positioning device for underground excavation tunnel grating steel frame

PendingCN114234797AEasy to adjust in place at one timeReduce weightUnderground chambersOptical detectionEngineeringSteel frame

The invention discloses a portable positioning device for underground excavation tunnel grating steel frames, which comprises a transmitting device, a receiving device, a positioning device and a positioning device, and is characterized in that the transmitting device is mounted on one grating steel frame and is used for transmitting a laser beam to the other grating steel frame; and the receiving device is arranged on the other grating steel frame and is used for receiving the laser beam emitted by the emitting device and calculating the incident angle of the laser beam. According to the technical scheme, a telescopic rod is replaced with the laser beam, the weight is greatly reduced, carrying is convenient, whether the grating steel frame is installed in place and the deviation amount of the grating steel frame and the accurate installation position are judged by measuring the incident angle of the laser beam, the grating steel frame can be conveniently adjusted in place at a time, adjustment time is remarkably shortened, time and labor are saved, and the working efficiency is improved. The use is convenient.

Owner:中水电四局华中(武汉)工程有限公司

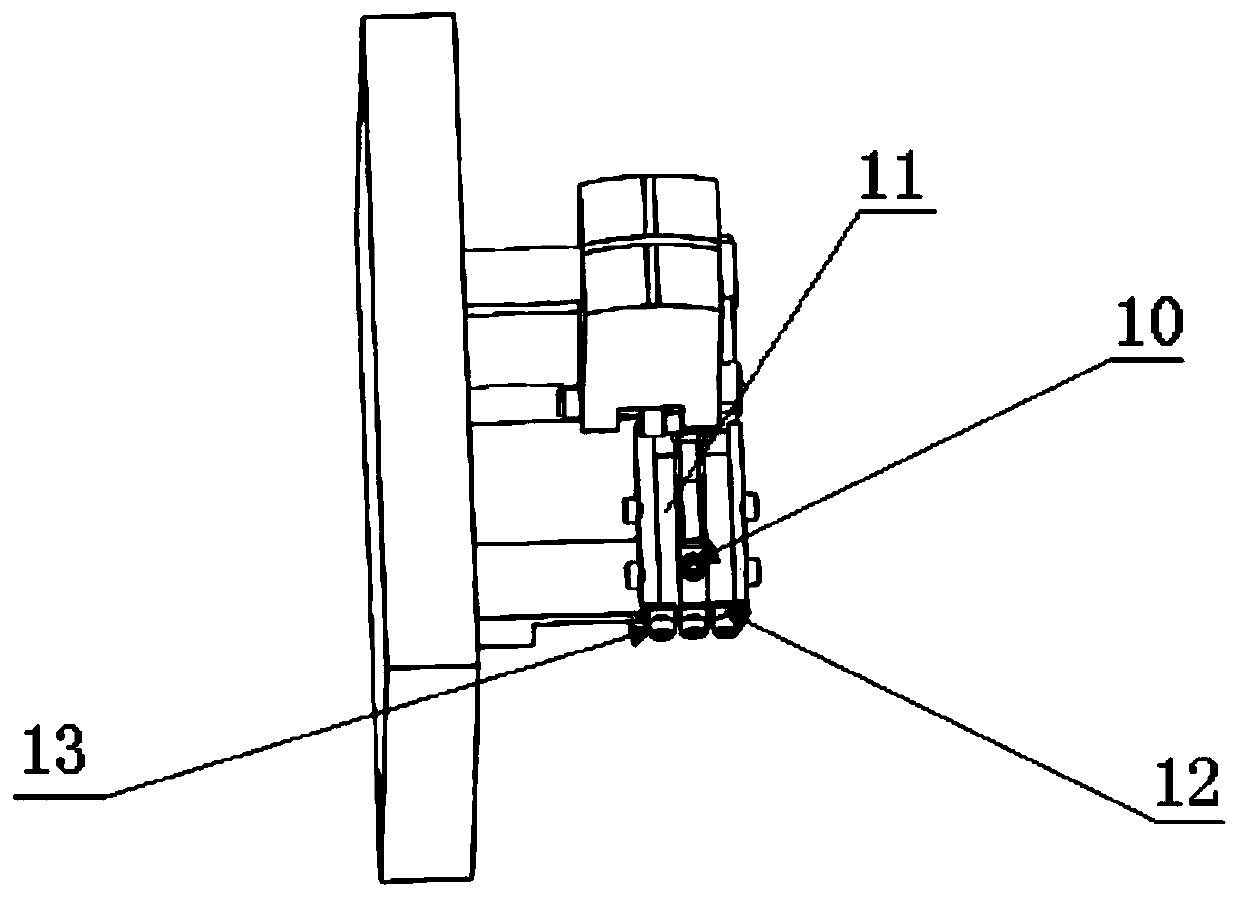

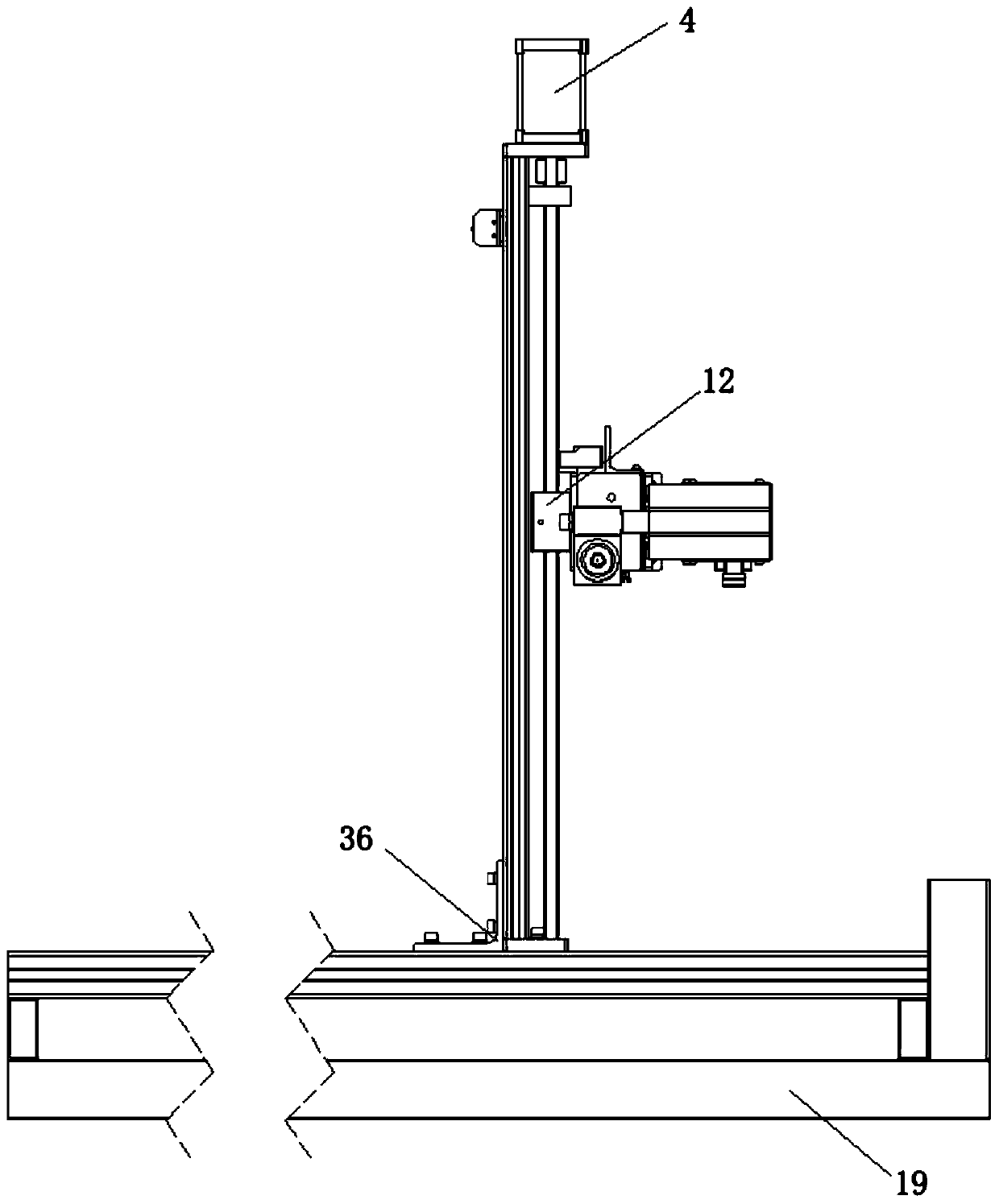

A spray gun automatic adjustment device

ActiveCN106391371BImprove regulation efficiencyReduce dependenceSpraying apparatusControl engineeringControl theory

The invention relates to the field of spraying equipment, in particular to an automatic spray gun regulating device which comprises a rotary regulating mechanism, an X-axis linear slide mechanism, a Y-axis linear slide mechanism and a spray gun, wherein the spray gun is mounted on the rotary regulating mechanism which is used for regulating a spraying angle of the spray gun; the rotary regulating mechanism is mounted on the X-axis linear slide mechanism which is used for driving the rotary regulating mechanism to move left and right; and the X-axis linear slide mechanism is mounted on the Y-axis linear slide mechanism which is used for driving the X-axis linear slide mechanism to move up and down. The automatic spray gun regulating device realizes free movement, in three dimensions of the X axis, the Y axis and the Z axis, of the spray gun, and the spraying angle of the spray gun is flexibly regulated through the rotary regulating mechanism, so that free regulation on the position of the spray gun and the spray angle of the spray gun is realized, various spray requirements can be met, and spray quality is improved.

Owner:SUZHOU BOHAN PLASTIC IRONWARE

Shoebox paperboard slotting equipment

PendingCN113733655AAdjustment time is shortEasy to operatePaper-makingBox making operationsStructural engineeringKnife holder

The invention discloses shoebox paperboard slotting equipment. The equipment comprises a rack and a conveying belt arranged on the rack and further comprises a fixing plate, a positioning plate and a tool rest arranged on the rack in a sliding mode, the fixing plate and the positioning plate are both located above the conveying belt, the positioning plate is arranged on the rack in a sliding mode in the direction close to or away from the fixing plate, the sliding direction of the tool rest and the sliding direction of the positioning plate are consistent, two slotting tools are arranged on the tool rest in a face-to-face or back-to-back sliding mode, the distances between the two slitting tools and the center line of the tool rest are consistent, a linkage mechanism used for driving the positioning plate and the tool rest to move in the same direction is arranged on the rack, and when the positioning plate and the tool rest are driven by the linkage mechanism to move, the displacement distance of the positioning plate is twice that of the tool rest. The shoebox paperboard slotting equipment has the effect of reducing the time consumption of equipment adjustment after the to-be-processed paperboard is changed.

Owner:温州捷华电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com