Shoebox paperboard slotting equipment

A technology for slotting equipment and cardboard, which is applied in paper/cardboard containers, papermaking, box making operations, etc., can solve the problems of cumbersome adjustment process, long equipment adjustment time, and need to be improved, etc., to achieve easy operation and reduce equipment adjustment time. , reduce the time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

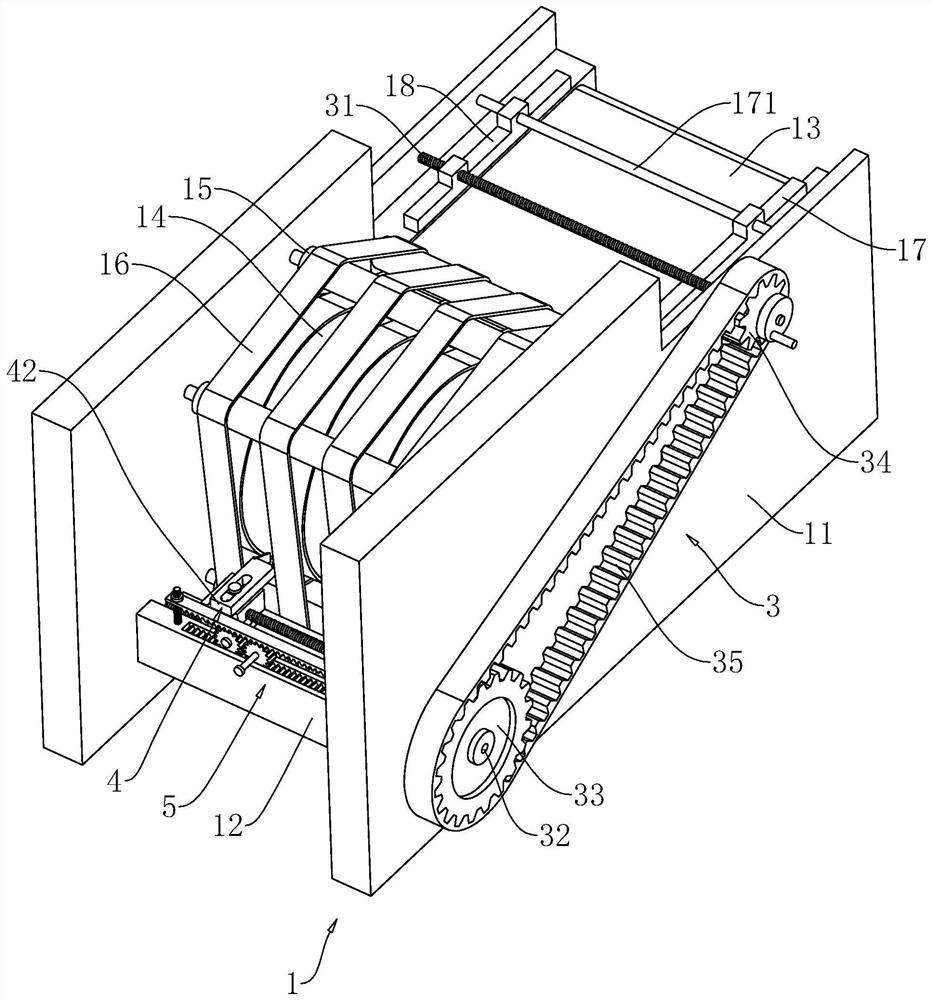

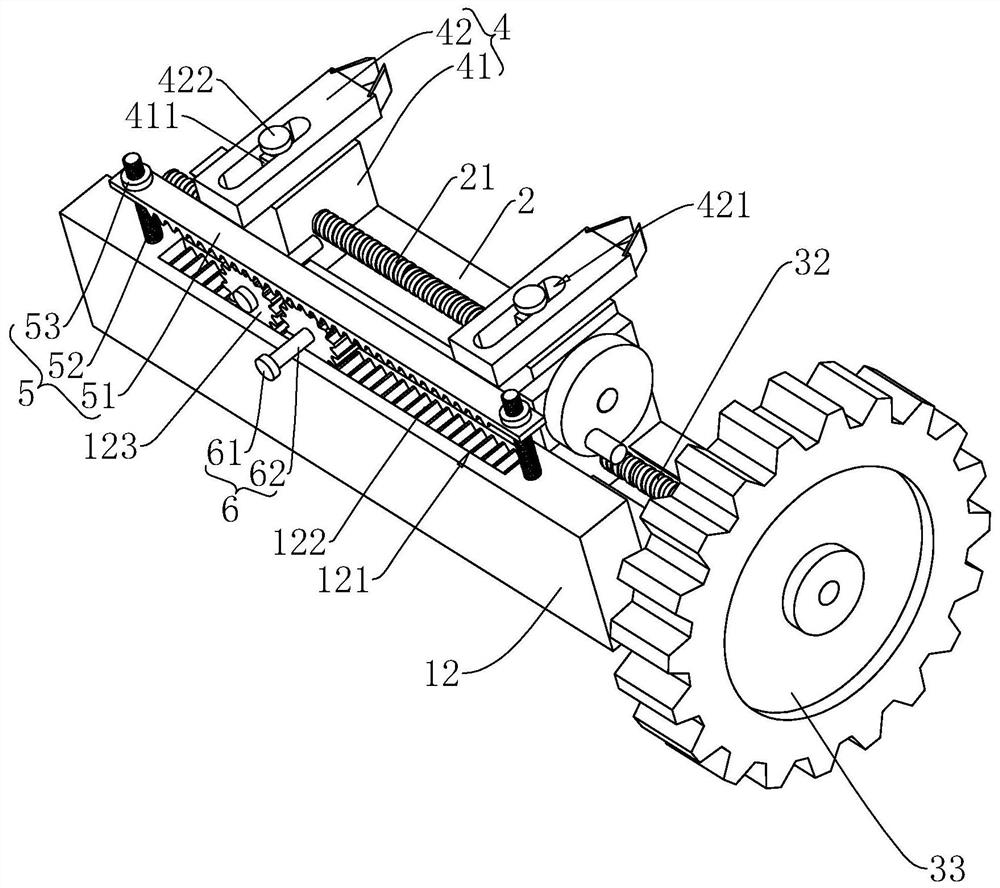

[0037] The following is attached Figure 2-4 The application is described in further detail.

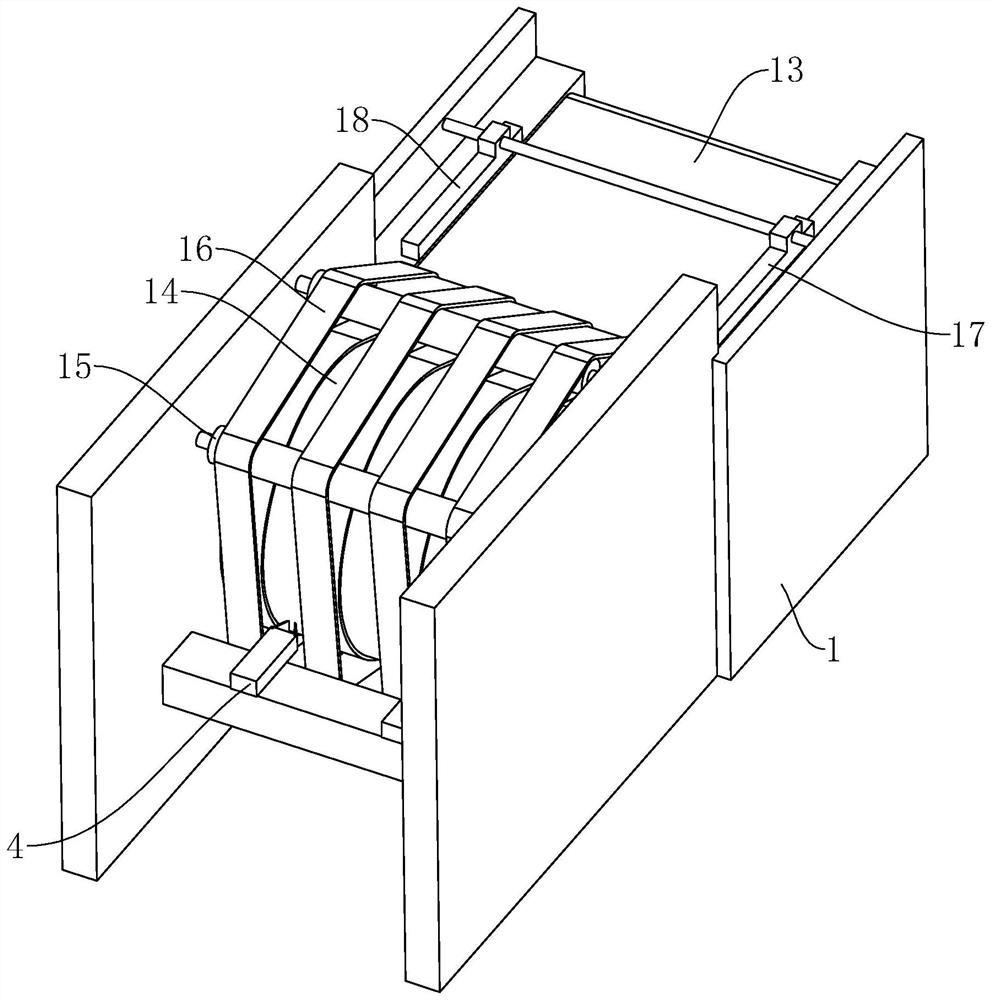

[0038] The embodiment of the present application discloses a shoe box cardboard slotting equipment. refer to figure 2 , image 3 , Shoebox cardboard slotting equipment includes frame 1, conveyor belt 13, turning roller 14, multiple conveyor rollers 15, multiple conveyor belts 16, fixed plate 17, positioning plate 18, knife rest 2, linkage mechanism 3, and two Slotting knife4.

[0039] refer to figure 2, the frame 1 includes a frame body 11 and a slide table 12 fixed on the frame body 11 , and a conveyor belt 13 is fixed on the frame body 11 and is used to transfer the cardboard to the turning roller 14 . The overturning roller 14 and the transmission roller 15 are all rotatably connected on the frame body 11, the transmission roller 15 is arranged circumferentially along the circumferential side wall of the overturning roller 14, and each transmission belt 16 is sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com