Seal paper receiving box of soft box packing machine

A packaging machine and carton technology, applied in the directions of packaging, transportation, packaging, labeling, etc., can solve the problems of incorrect positioning of seals, reduce equipment operation efficiency, increase labor intensity, etc., and achieve short adjustment time and reduce adjustment. Difficulty and labor intensity, and the effect of improving equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

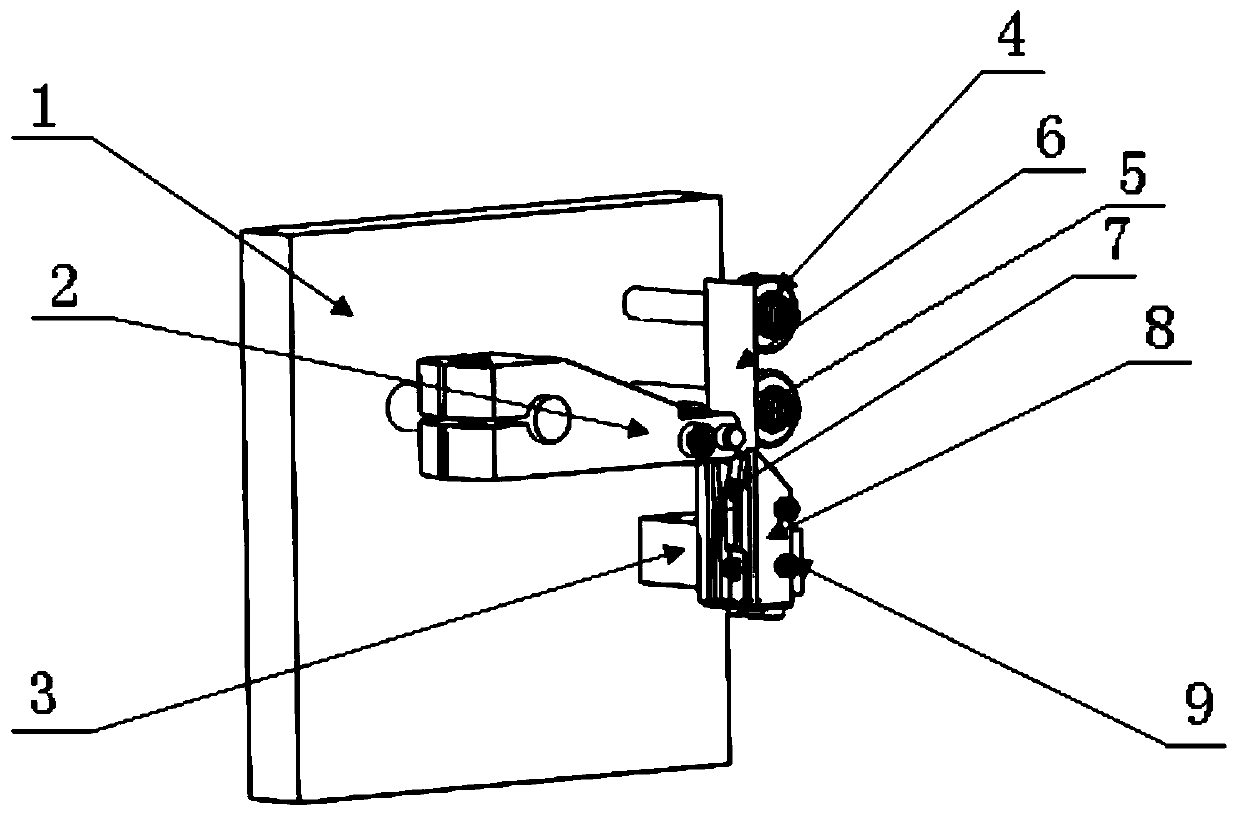

[0024] Such as figure 1 As shown, this application relates to a technical solution for a new type of seal splicing carton for ZB25 soft box packaging machine, including a supporting wallboard. In this embodiment, the supporting wallboard is a square plate-shaped structure. In other implementations of this application For example, the supporting wallboard can be set in other shapes according to needs and spatial positions, such as rectangle, trapezoid, etc., and the supporting wallboard is used to be fixed on other devices, so as to cooperate with the conveying device to seal the soft-packed cigarettes.

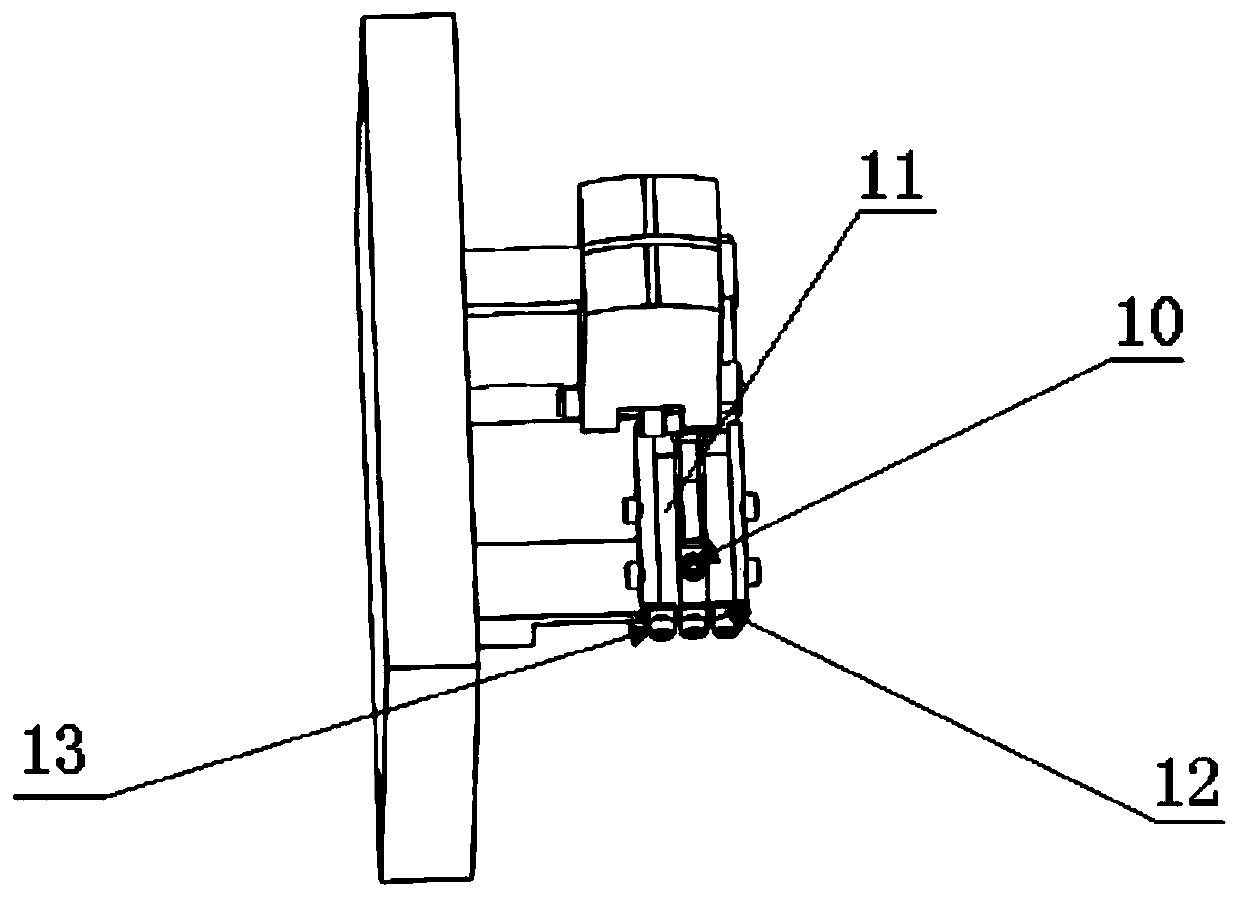

[0025] The seal splicing box of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com