Detection calibration device of coolant pump rotating speed monitoring system and detection calibration method of detection calibration device

A technology for detecting and calibrating devices and monitoring systems, which is applied in the direction of testing/calibrating of speed/acceleration/shock measuring equipment, measuring devices, speed/acceleration/shock measurement, etc., to achieve the effect of filtering out interference signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0050] During the overhaul of the power plant, a coolant pump speed monitoring system testing and calibration device is used to perform testing and calibration of the entire coolant pump speed monitoring system on site.

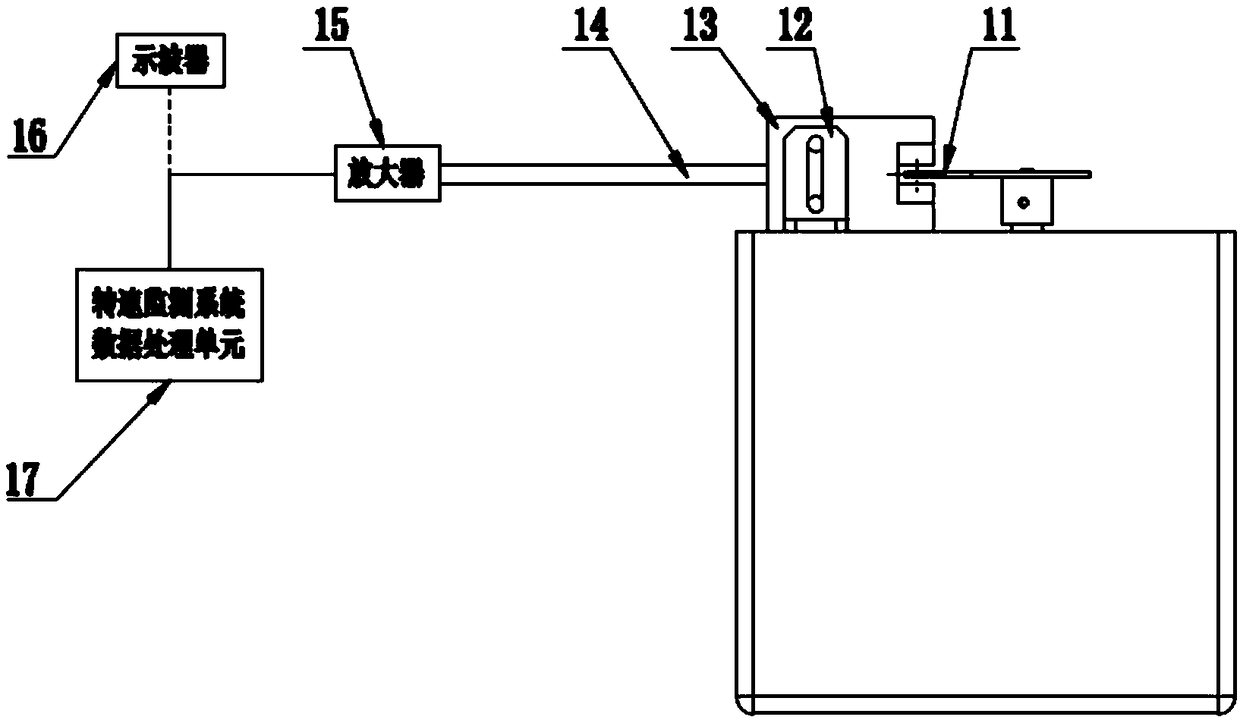

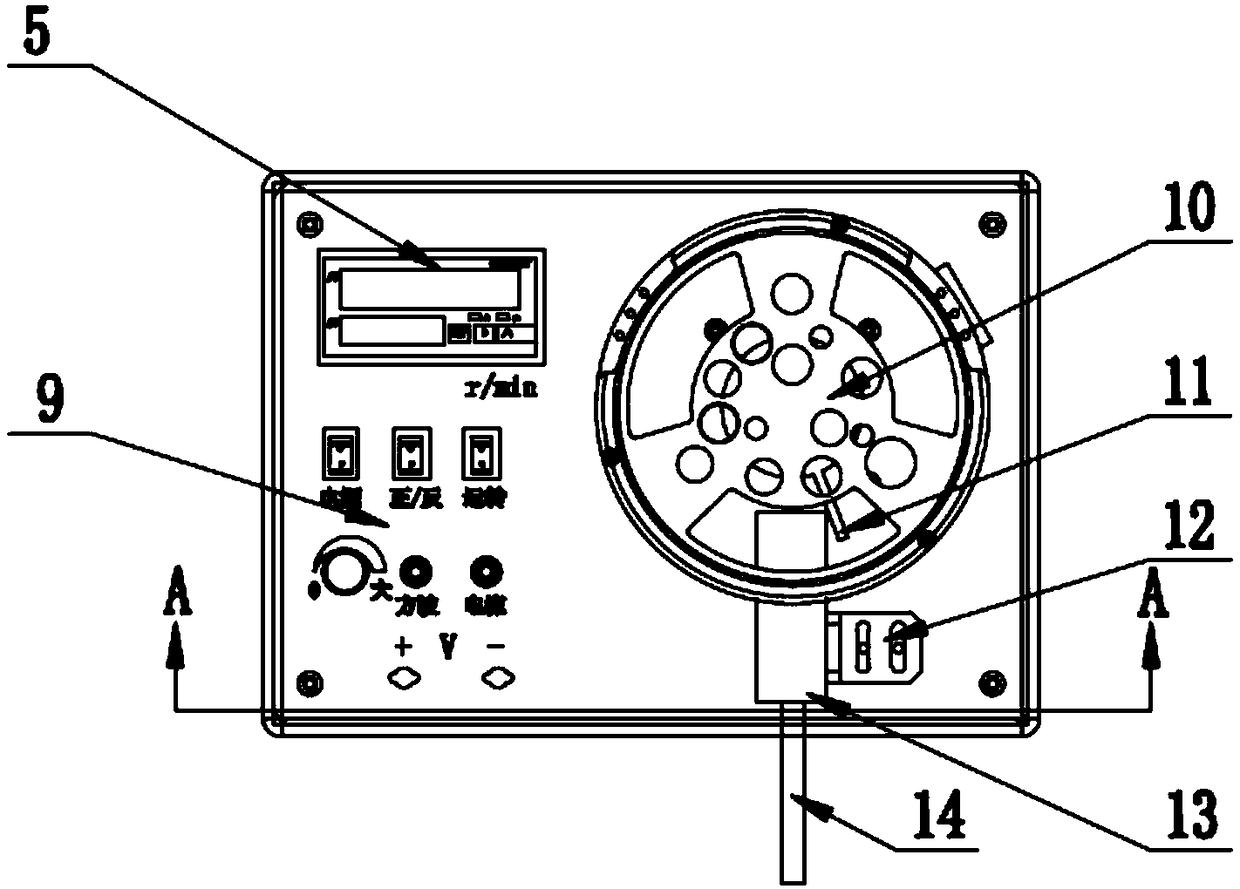

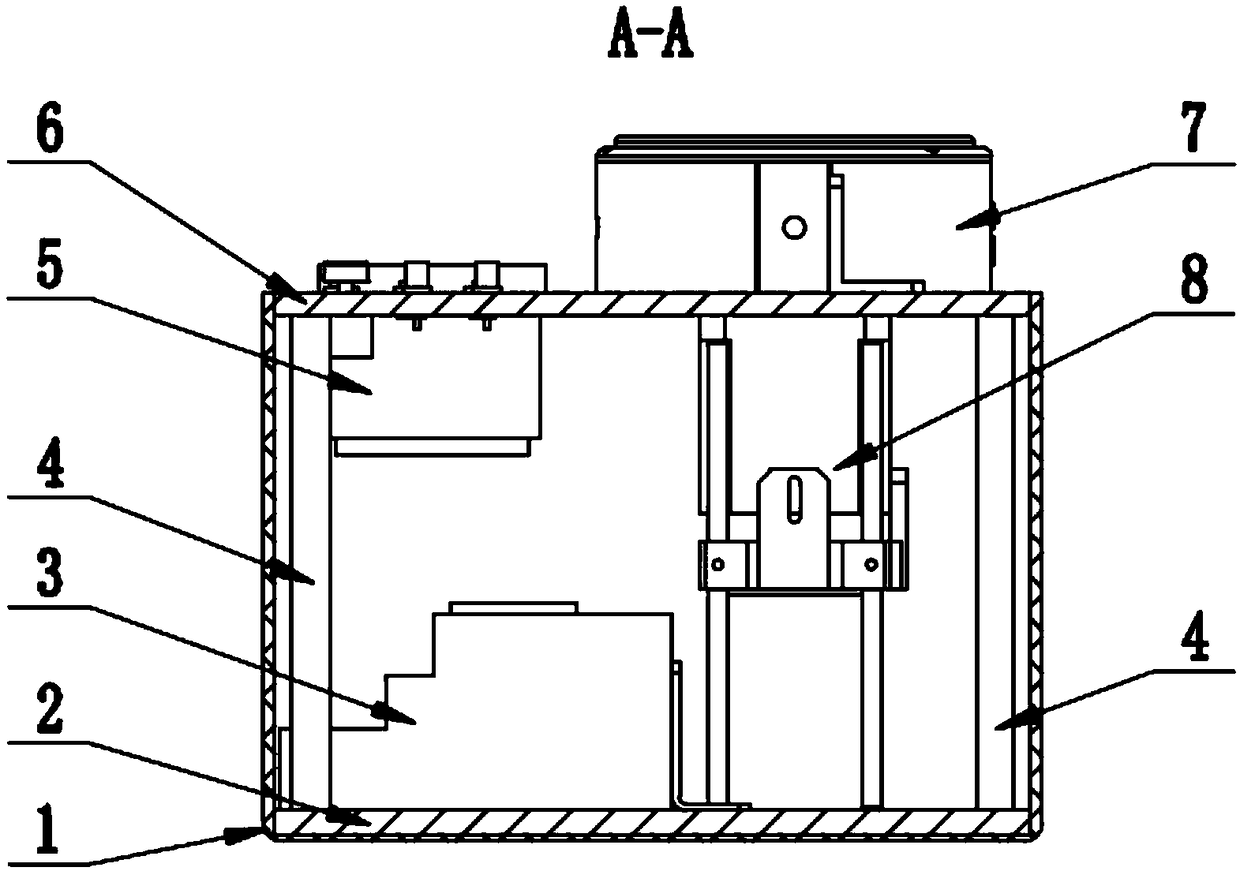

[0051] First install the disassembled sensor 13 on the detection and calibration device of the coolant pump speed monitoring system, then connect the output signal of the sensor 13 to the input end of the amplifier 15 through the coaxial cable 14, and then pass the amplifier 15 to the tested speed signal Perform amplification and filtering. Within the scope of the tested coolant pump speed monitoring system, select the six points of speed as 300rpm, 600rpm, 900rpm, 1200rpm, 1500rpm, and 1800rpm as the detection reference points, and then adjust the stepless speed regulation knob 901 to make the speed of the device reach the selected Then record the output waveform, high and low level, and peak-to-peak output voltage of the sensor 13 at these 6 points; finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com