Automatic centering device of electro-spindle reliability test bench based on dragging

An automatic centering and drag-and-loading technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of unable to monitor the generation and elimination of singular data in time, and consuming a lot of manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

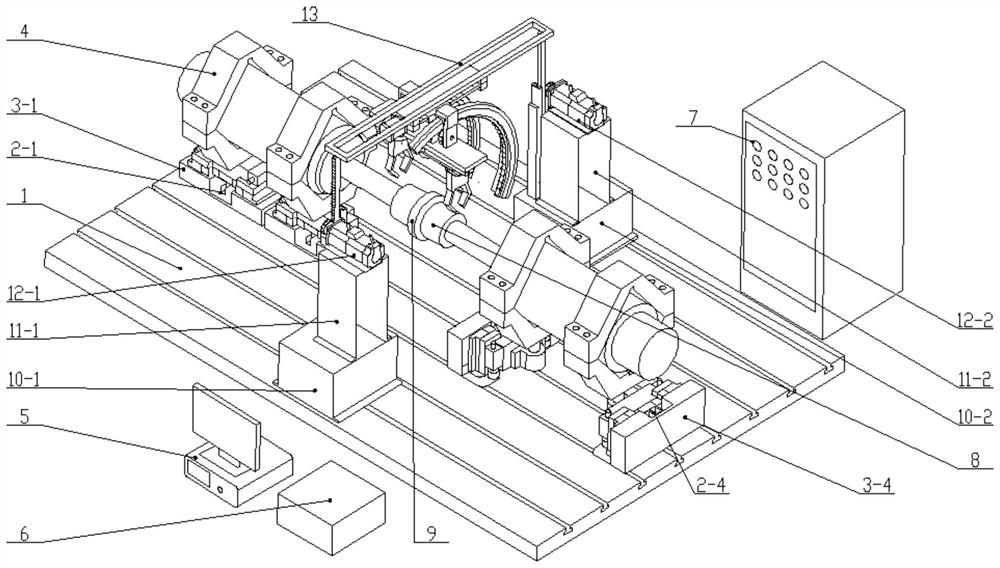

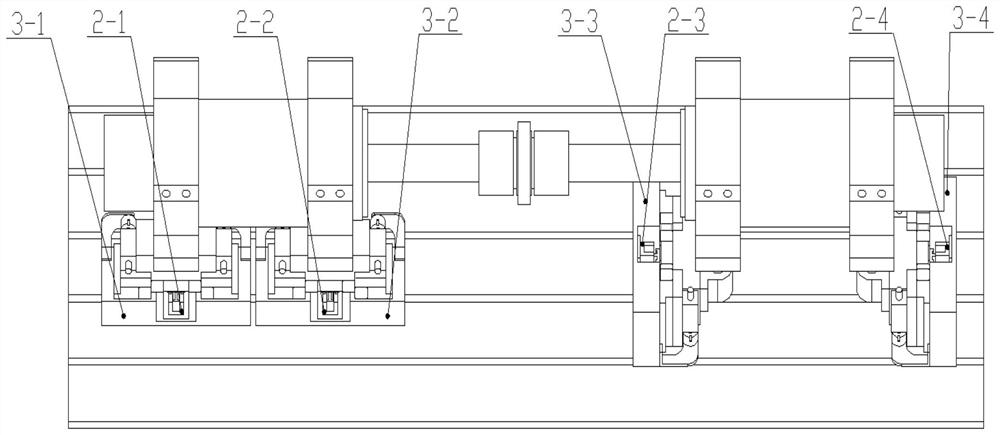

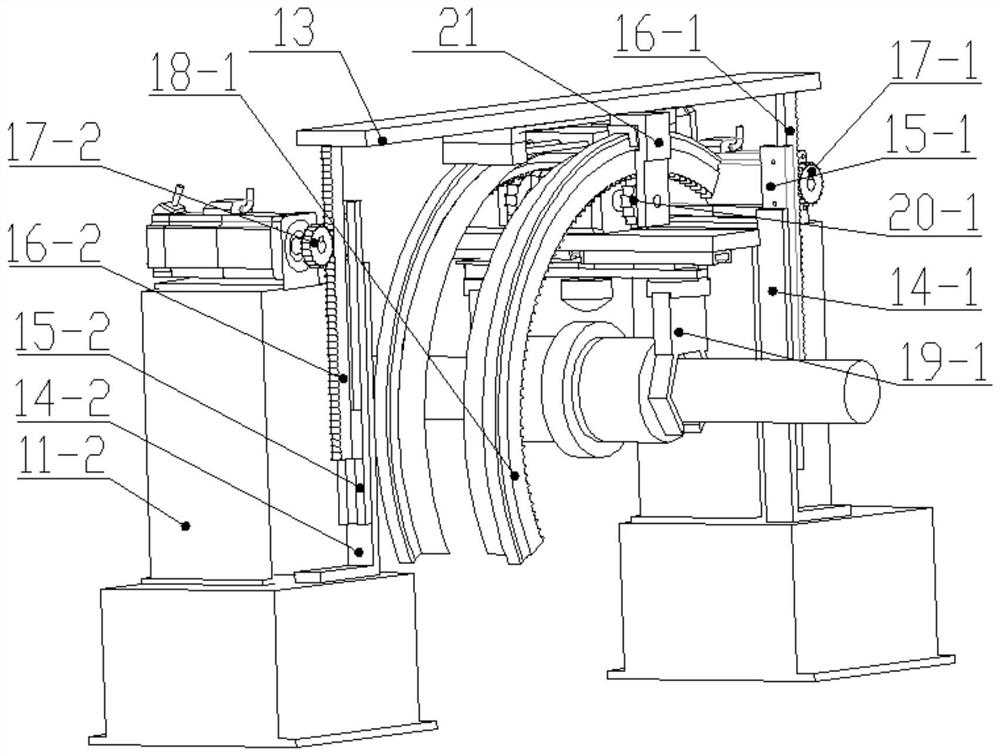

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] Since the alignment of the two tested spindles cannot be detected during the test, the alignment of the two tested spindles is usually detected at the beginning and end of the test, but the detection results at the end of the test are usually misalignment The difference has exceeded the maximum value required by the test bench stress, which leads to the generation of data singularities and it is impossible to determine when the test bench starts to generate singular data. In other words, it is impossible to determine which data is exceeding the test bench. It is generated under the condition of misalignment, and all test data will be invalidated. However, artificially detecting and adjusting the alignment of the test bench will interrupt the reliability test for a long time and affect the test efficiency. When the test is stopped, it is likely that the misalignment has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com