A pointer homing type automatic adjustment and measurement tripod

A tripod and pointer technology, applied in the field of measurement, can solve the problems of laborious manual adjustment, time-consuming, and time-consuming adjustment delaying the measurement process, etc., so as to improve the measurement accuracy, improve the measurement efficiency, and shorten the time-consuming adjustment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

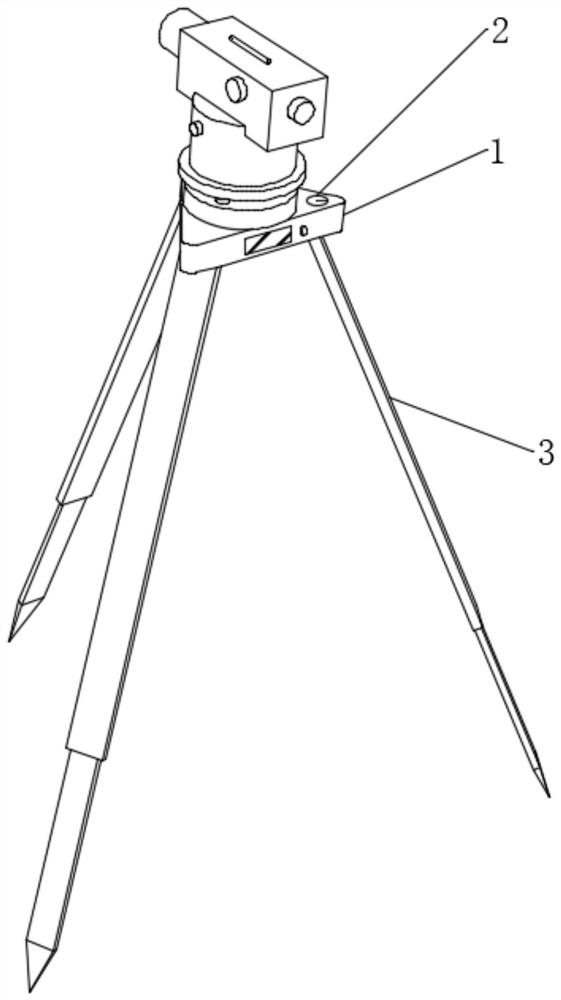

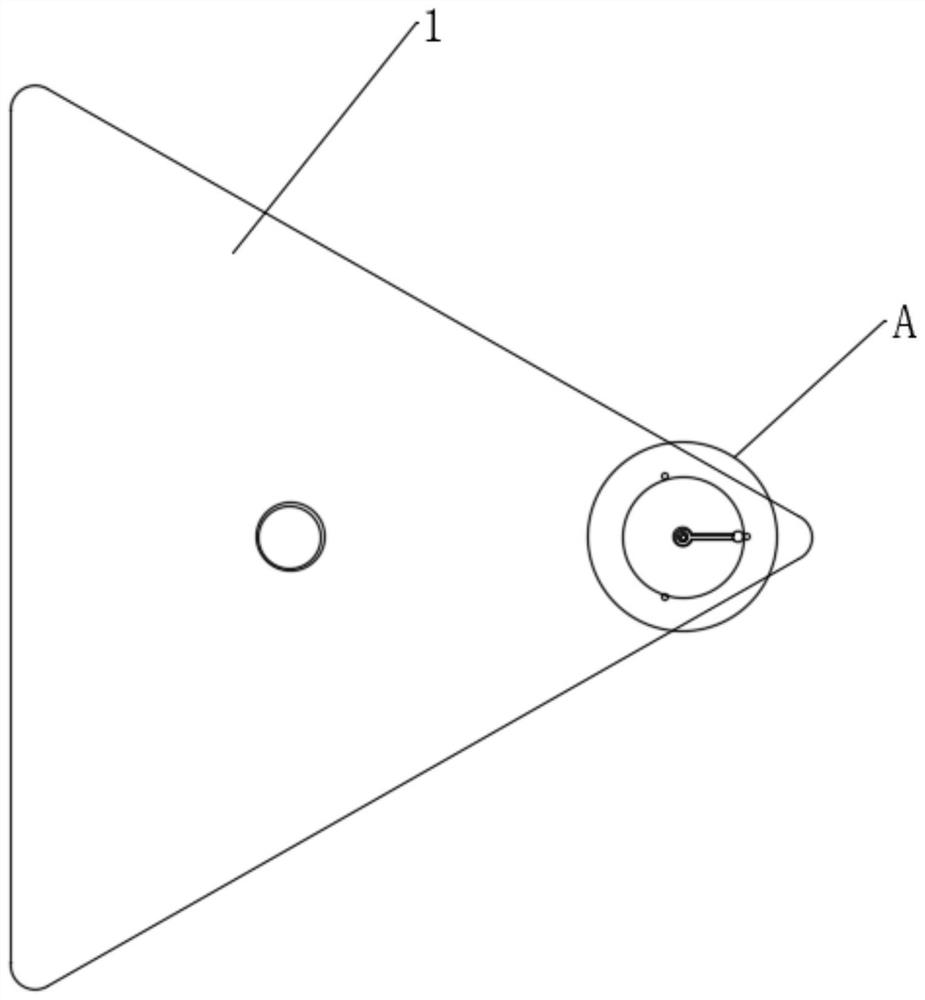

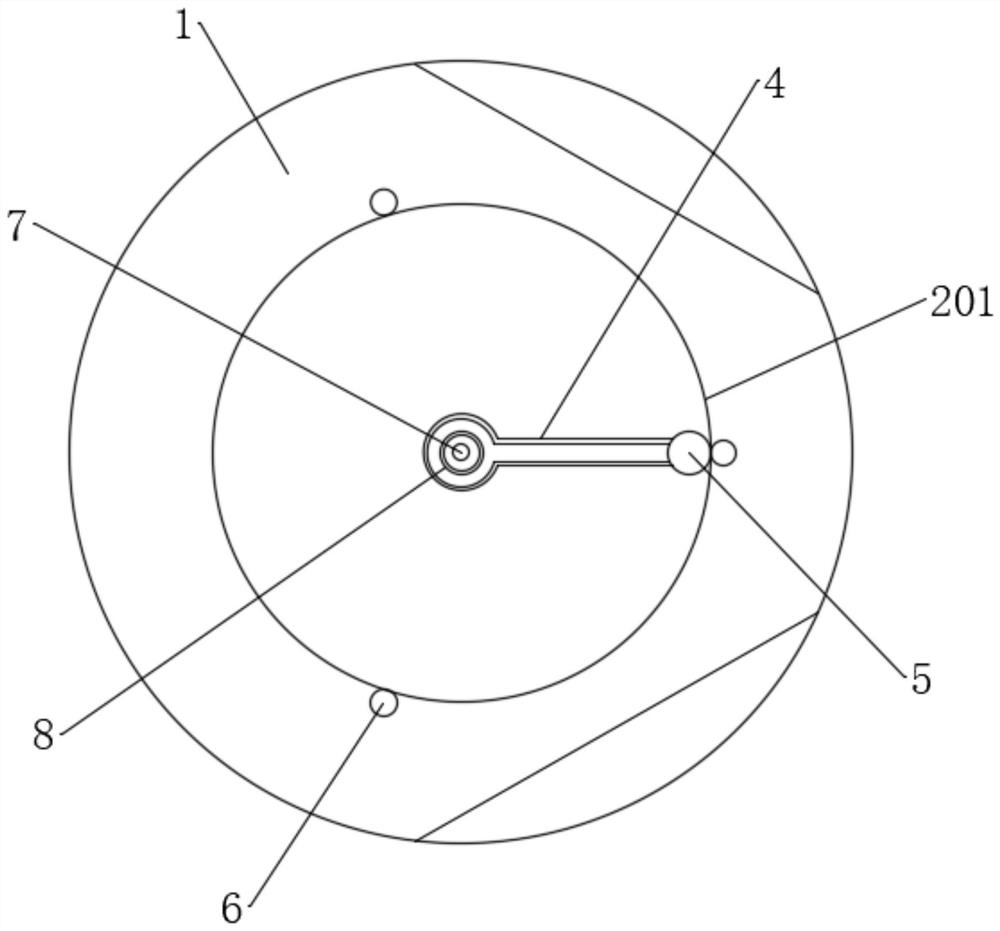

[0044] see figure 1 , a pointer homing type automatic adjustment and measurement tripod, including an instrument placement table 1, the lower end of the instrument placement table 1 is connected with three triangularly distributed self-elevating outriggers 3 through pin shaft rotation, please refer to Figure 7 , the self-lifting outrigger 3 includes a fixed part 301 installed on the lower end of the instrument placing table 1, the lower end of the fixed part 301 is drilled with an adjustment groove, a sliding part 302 is slidably connected in the adjustment groove, and an end lock is fixedly installed on the bottom end wall of the adjustment groove Cylinder 303, and the output end of the end lock cylinder 303 is fixedly connected with the fixing part 301, the end lock cylinder 303 has extremely high working stability, even if there is a power failure, it will not drop suddenly, and it can still maintain the stability after adjustment status, so that the tripod has the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com