A Punch Position Adjustment Mechanism in Continuous Drawing Die

A technology for deep drawing dies and adjustment mechanisms, applied in the field of stamping dies, can solve the problems of increasing the cost of grinding punches and processing gaskets, time-consuming and laborious installation and debugging, and inability to directly adjust the height, so as to achieve simple structure and fast adjustment speed. , Adjust the effect of less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

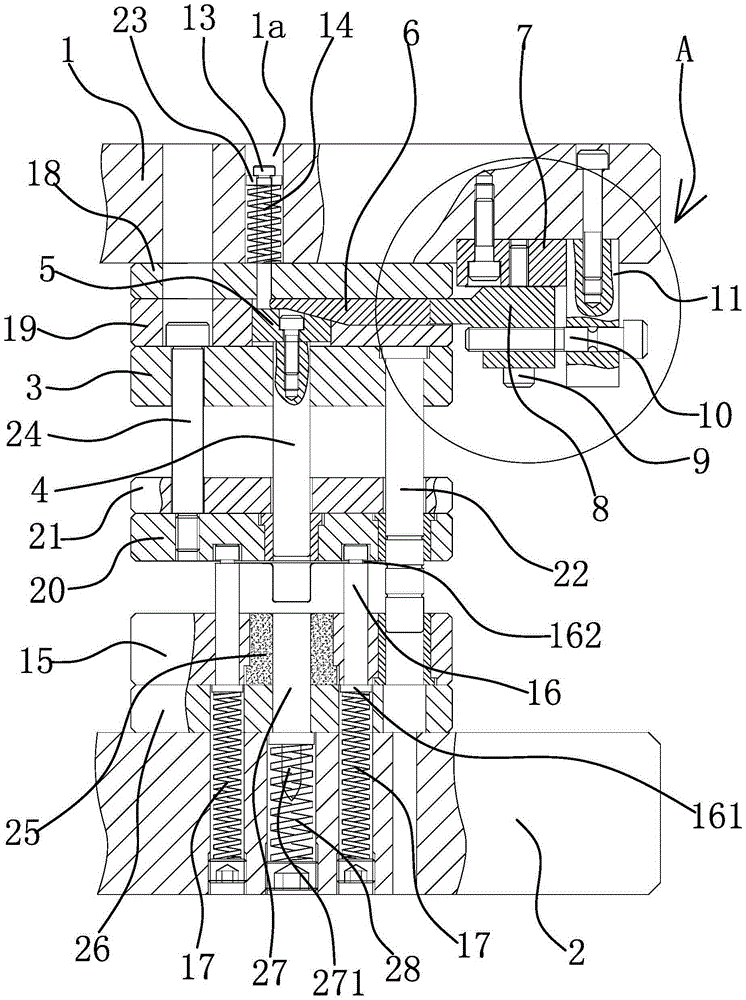

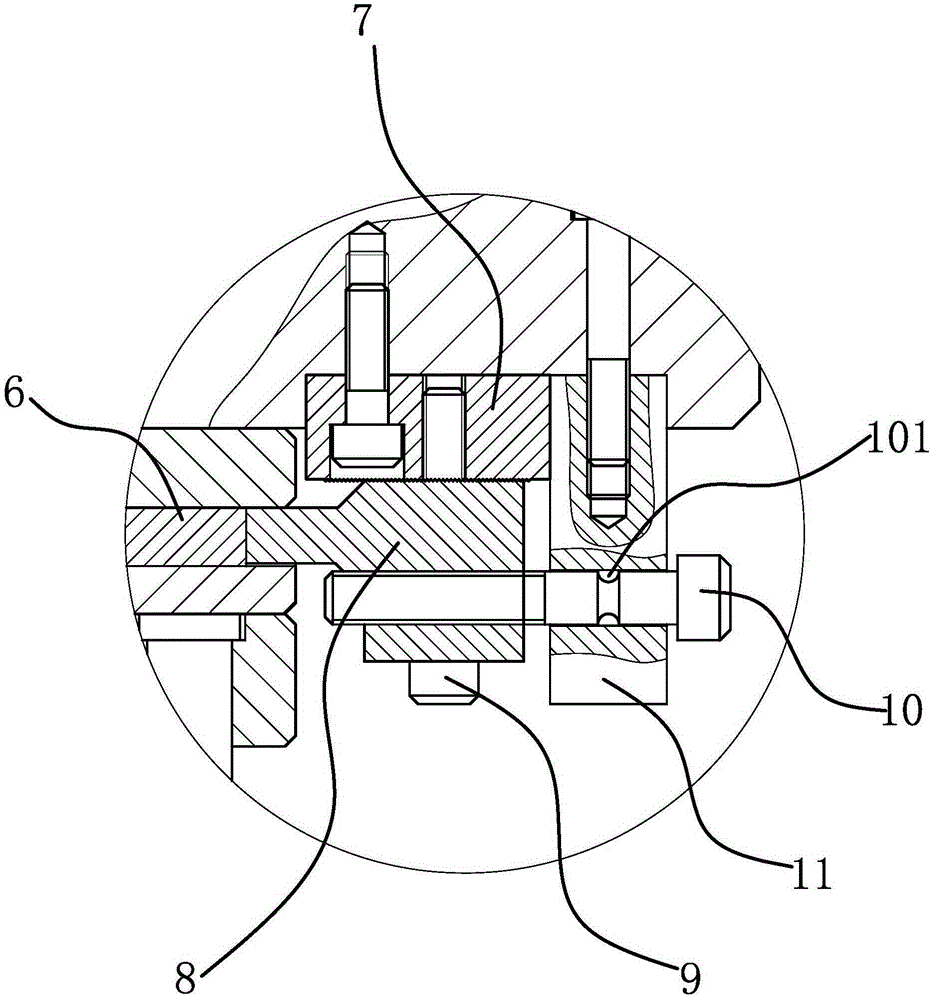

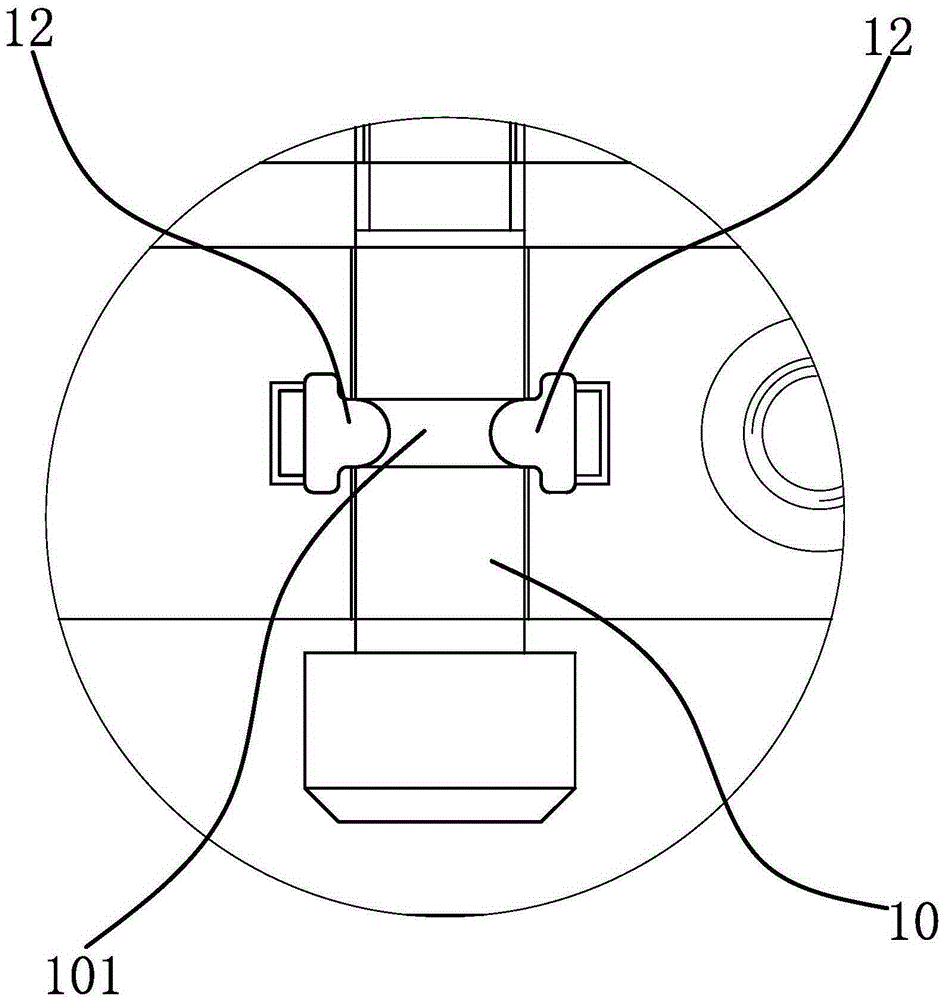

[0036] The continuous drawing die comprises an upper die base 1 and a lower die base 2, and a punch fixing plate 3 is fixed on the upper die base 1. Punch 4 is housed on the punch fixed plate 3, and punch 4 here can be drawing punch and shaping punch etc. The punch position adjustment mechanism in the continuous drawing die is arranged on the upper die base 1, including punch slide block 5, adjustment slide block 6, adjustment assembly and locking assembly.

[0037] Specifically, as figure 1 As shown, the punch fixing plate 3 is installed on the upper die base 1, and an upper backing plate 18 and a lining plate 19 are also installed between the punch fixing plate 3 and the upper die base 1, and the punch fixing plate 3 and the upper backing plate 18 And lining plate 19 is positioned on the upper mold base 1 by positioning pin, and is fastened by screw, and small guide post 22 is also installed on the punch fixed plate 3. There is a chute 1 on the liner 19, the punch slider 5...

Embodiment 2

[0043] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the adjustment assembly includes a sliding block, the sliding block is slidably connected on the punch fixing plate 3, and the sliding block is connected with the adjustment The slide block 6 is fixedly connected, the slide block has several positioning holes, and the punch fixing plate 3 has positioning pins which can cooperate with the positioning holes respectively. When it is necessary to adjust the position of the punch 4, first pull out the positioning pin from the positioning hole, push the sliding block to slide relative to the punch fixing plate 3, and drive the adjustment slider 6 to approach or move away from the punch slider 5, so that the punch The mold 4 rises or falls; after the adjustment is completed, insert the positioning pin into another corresponding positioning hole, so that the sliding block is fixedl...

Embodiment 3

[0045] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the locking assembly includes at least one disc spring sleeved on the punch 4, the disc spring One end leans against the punch fixing plate 3 , and the other end leans against the punch slide 5 . The belleville springs are easy to install and the cost is low; and the number and elastic force of the belleville springs can be selected according to the required elastic force, which has little influence on the structure of the continuous drawing die itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com