A button valve core and a faucet

A key and valve core technology, applied in the valve core field, can solve the problems of difficulty in finding the right direction of rotation, insufficient rotation force, waste of water resources, etc., and achieve a new experience and feeling, novel operation mode, and the effect of saving water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

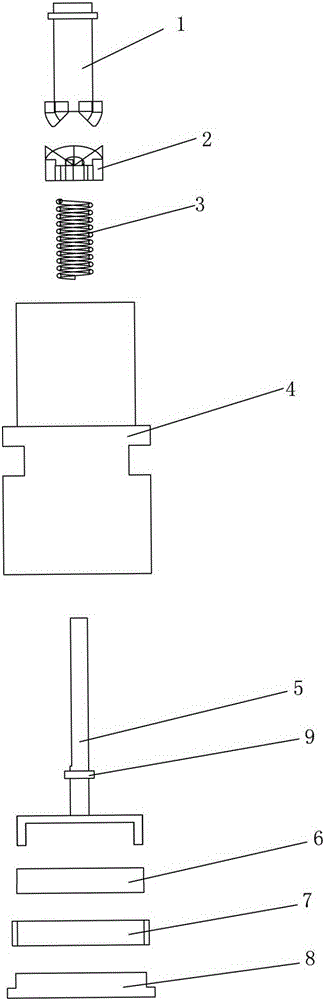

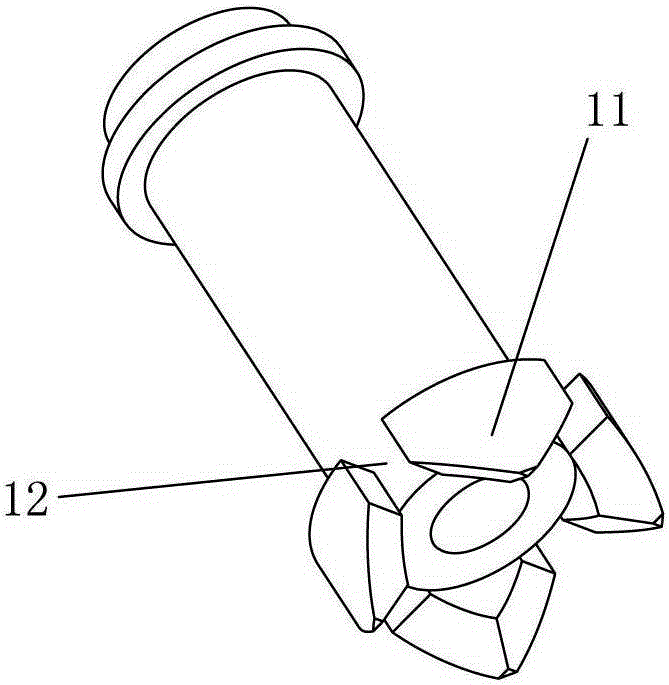

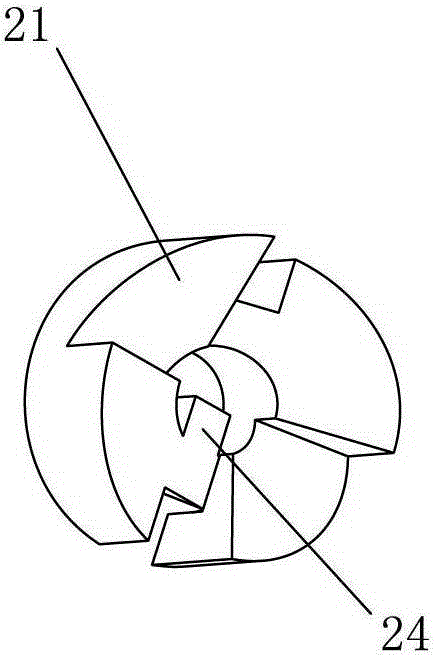

[0027] Embodiment, please refer to the accompanying drawings, a button valve core of the present invention includes a valve housing 4, a static valve plate 7, a moving valve plate 6 and a valve stem 5, and the bottom of the valve housing 4 forms a cavity with an open bottom end body 44, the side of the cavity 44 is provided with an opening 41, and the top of the valve housing 4 forms a channel 42 which communicates with the cavity 44 along its axial direction and has an open top; the static valve plate 7 and the moving valve plate 6 are coaxially set on In the cavity 44 of the valve casing 4, and fit each other, a rubber pad 8 is placed at the bottom of the cavity 44 of the valve casing 4 during specific installation, and the static valve plate 7 is positioned and sealed by using the rubber pad 8; The valve stem 5 is sealed and sleeved in the valve casing 4, and the bottom end of the valve stem 5 is fixedly connected with the movable valve plate 6, and the top of the valve stem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com