Ultralow-temperature impact test device and test method thereof

A technology of impact testing and low-temperature equipment, which is applied in the field of ultra-low temperature testing, can solve problems such as changes in material properties of samples, inconsistencies in actual conditions, and troubles for experimental testers, and achieve the effect of reducing the possibility of phase transition and timely observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

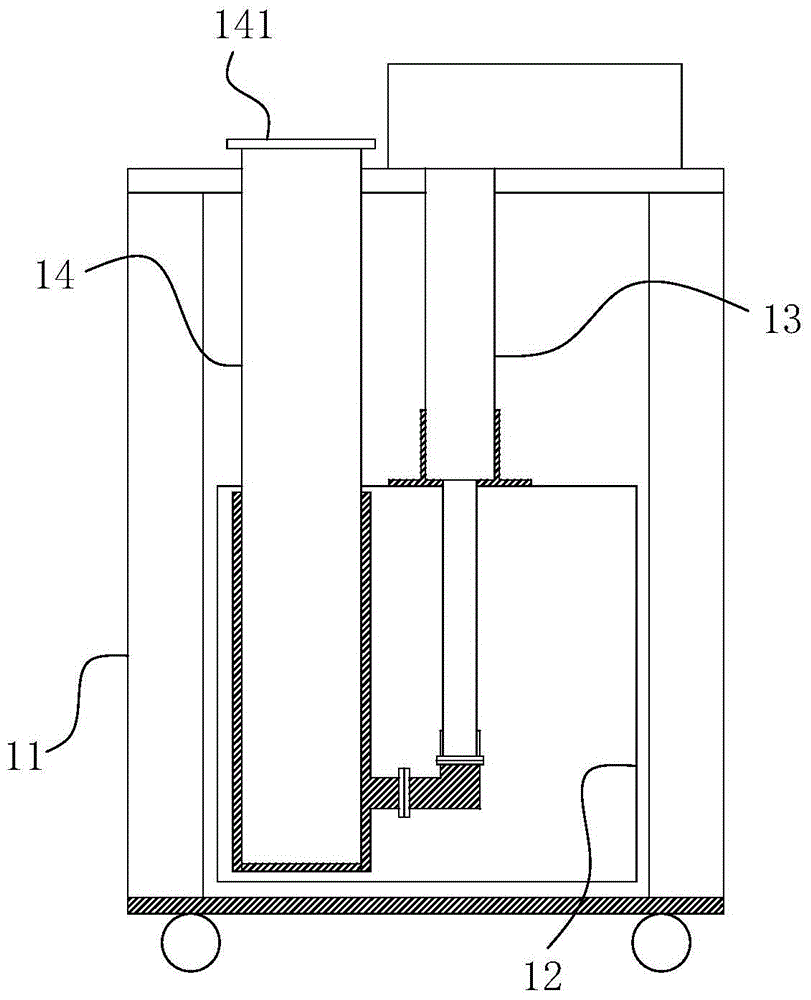

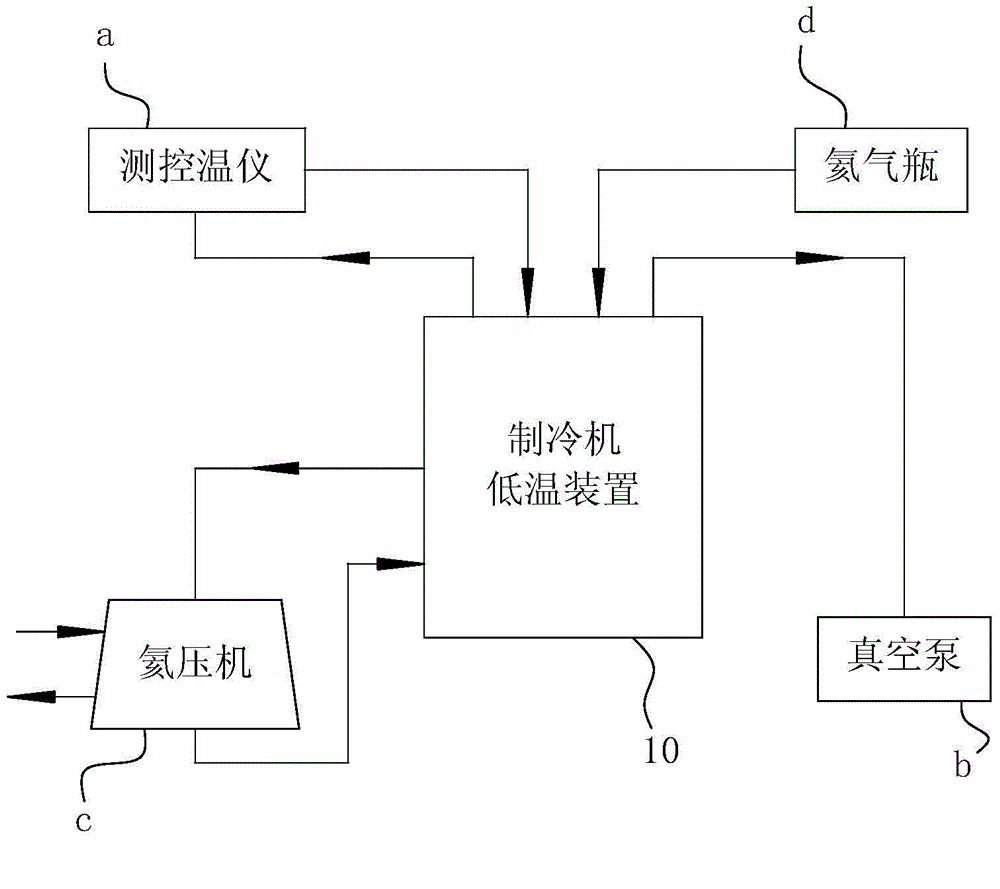

[0038] For ease of understanding, here in conjunction with accompanying drawing, specific testing device of the present invention and its operation process are further described as follows:

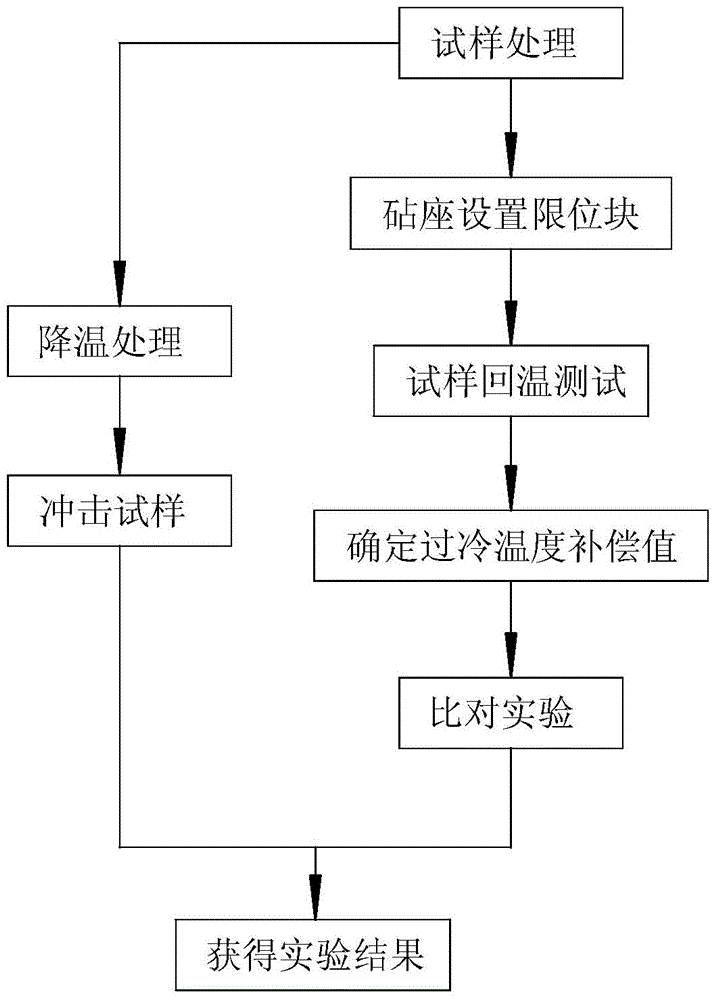

[0039] In fact, the purpose of the present invention is to realize the controllable temperature of the test down to -263°C, overcome the inaccurate test temperature and the difficulty of heat preservation, and provide an ultra-low temperature impact performance test system and corresponding test method. Considering the lowest value of the controllable temperature in the current test, it is obvious that the closer it is to the lowest value, the more difficult it is to obtain the temperature, especially for ultra-low temperature test samples close to the lowest temperature value, once the compensation value of the supercooling temperature is too large , resulting in the predetermined minimum temperature of the experiment being lower than the minimum value of the controllable temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com