Cleaning kettle for cleaning precision parts

A technology in parts and operations, which is applied in the field of precision parts cleaning, can solve problems such as poor cleaning effect of micropores and slits, cleaning damage of precision parts, waste of water resources, etc., to avoid a large amount of loss and reduce treatment waste Liquid and cost, the effect of small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

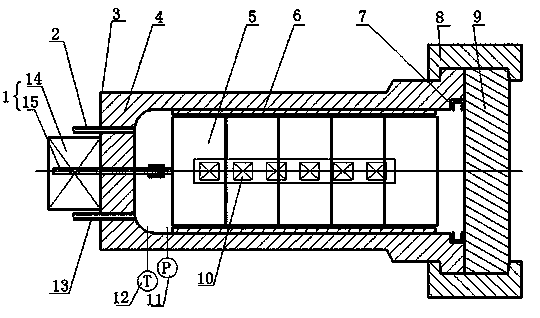

[0026] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

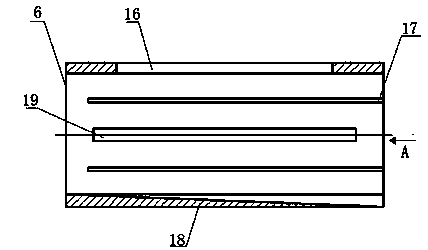

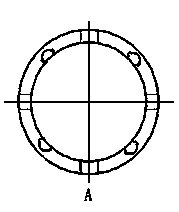

[0027] With reference to the accompanying drawings, a cleaning kettle used in precision parts cleaning operations includes an inlet pipe 2, an outlet pipe 13, a head 9, a clamp 8, a pressure gauge 11, and a temperature gauge 12. The inner jacket 6 is A thin-walled cylinder with four rectangular through grooves, the top groove 16 is installed with the nozzle pipe 23, the lower groove 18 is the outlet for waste debris, the grooves are inclined at 10° to 20°, and the two horizontal grooves 19 are installed with ultrasonic transducers 10 , Four chain grooves 17 are symmetrically distributed in the inner jacket 6, so as to facilitate the installation of chain beads 20. The cleaning kettle 3 is tightly connected with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com