Starter ball assembly device

An assembly device and starter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient disassembly of ball barrels, many standard parts and processed parts, complex lifting mechanism, etc., and achieve simple structure, The effect of preventing material accumulation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

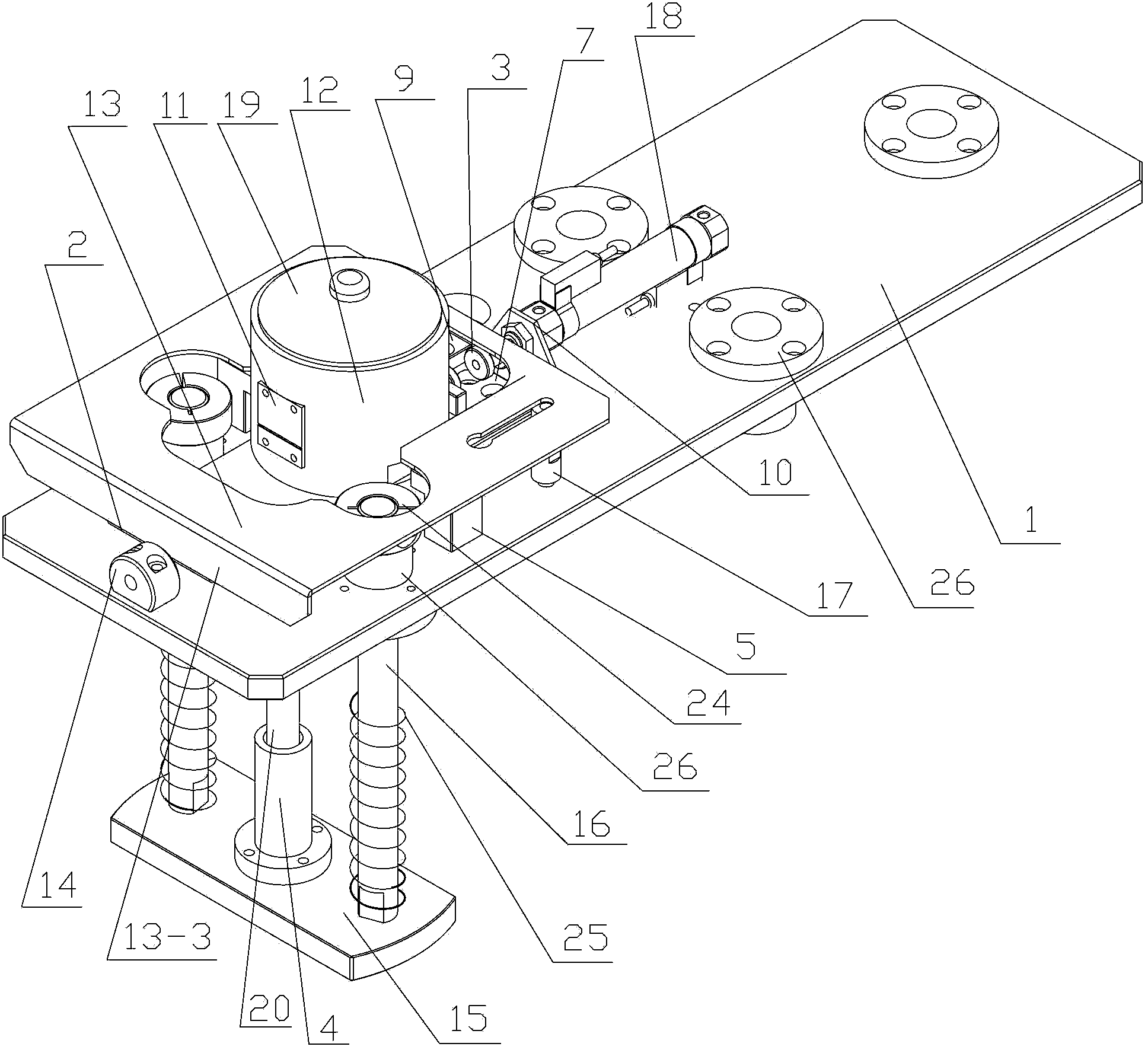

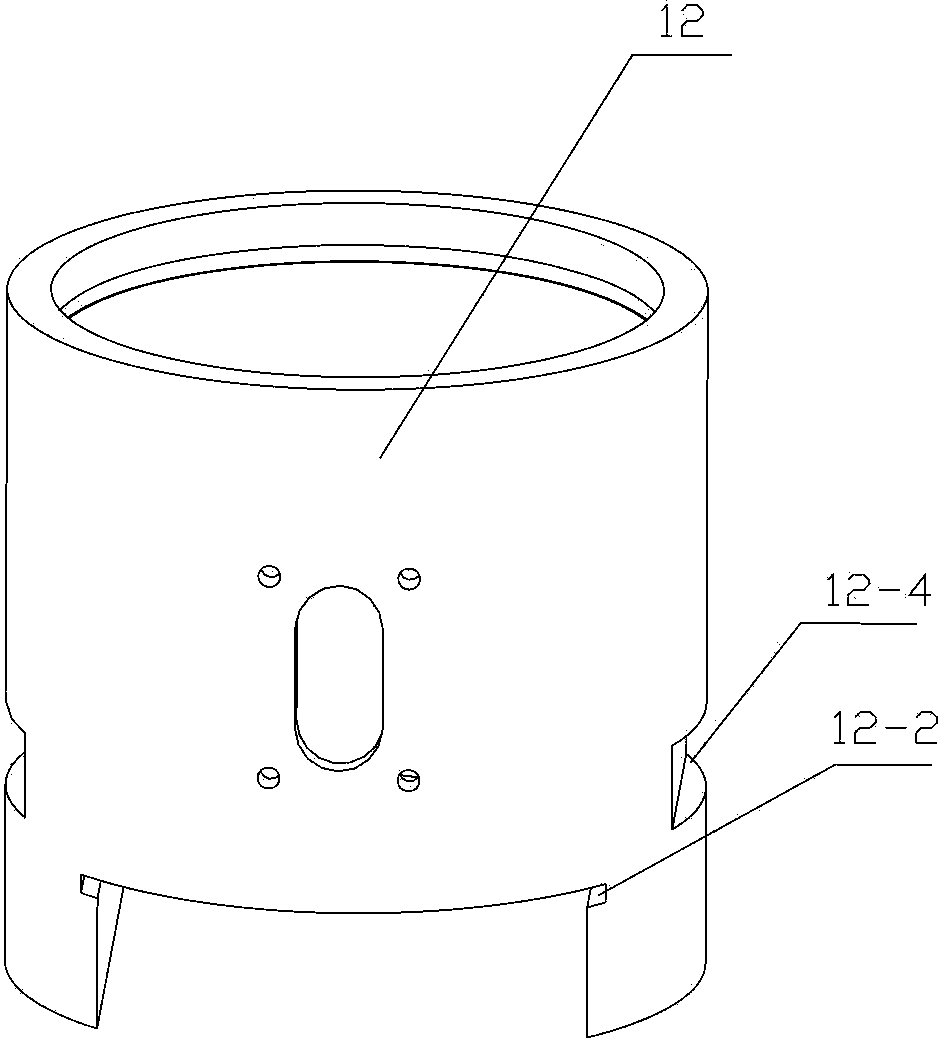

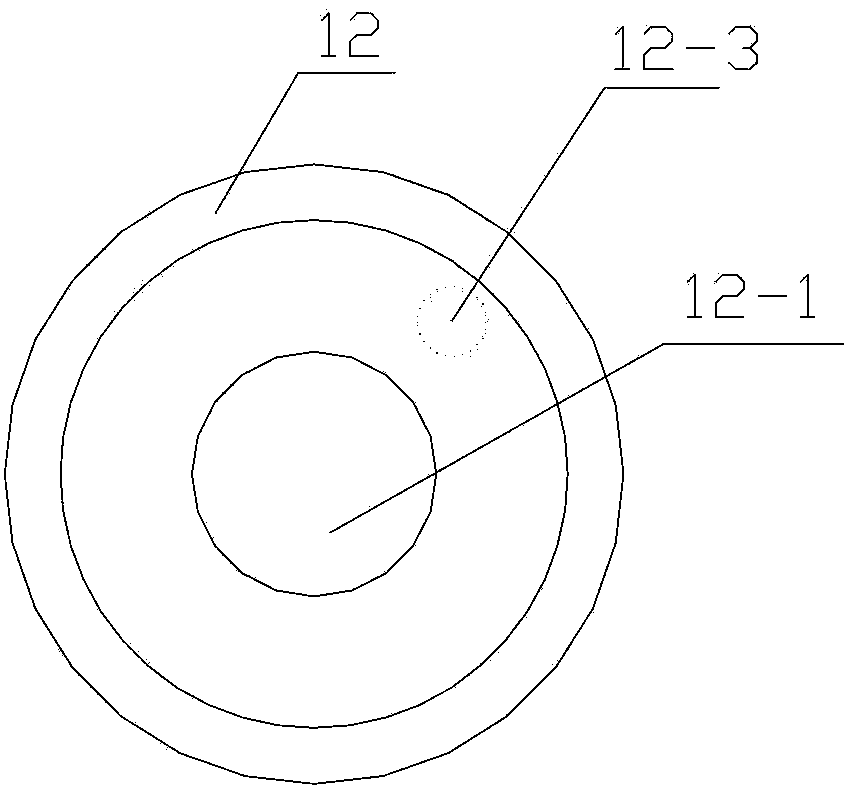

[0024] A starter ball assembly device, such as figure 1 , Figure 5 with Image 6 As shown, it includes a ball feeding mechanism, a ball barrel mechanism, a ball material passage mechanism, and a ball lifting mechanism. The ball feeding mechanism is installed at the rear of the ball barrel mechanism, and the ball barrel mechanism is installed at the front of the ball barrel mechanism. The ball lifting mechanism is installed at the rear of the ball feeding mechanism. Such as figure 1 As shown, the ball feeding mechanism includes a ball tooling plate 1, a guide rail bottom plate 7, a cylinder 18, a guide plate 9 and a ball sliding plate 2. The cylinder 18 is installed on the tooling plate 1, and the cylinder 18 is installed through the cylinder mounting plate 28 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com