Oil cooler connector fastener

A technology for fasteners and oil coolers, applied in the direction of pipes/pipe joints/fittings, through components, sleeves/sockets, etc., can solve problems such as inconvenient maintenance, to ensure sealing, avoid transitional sliding, and facilitate The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

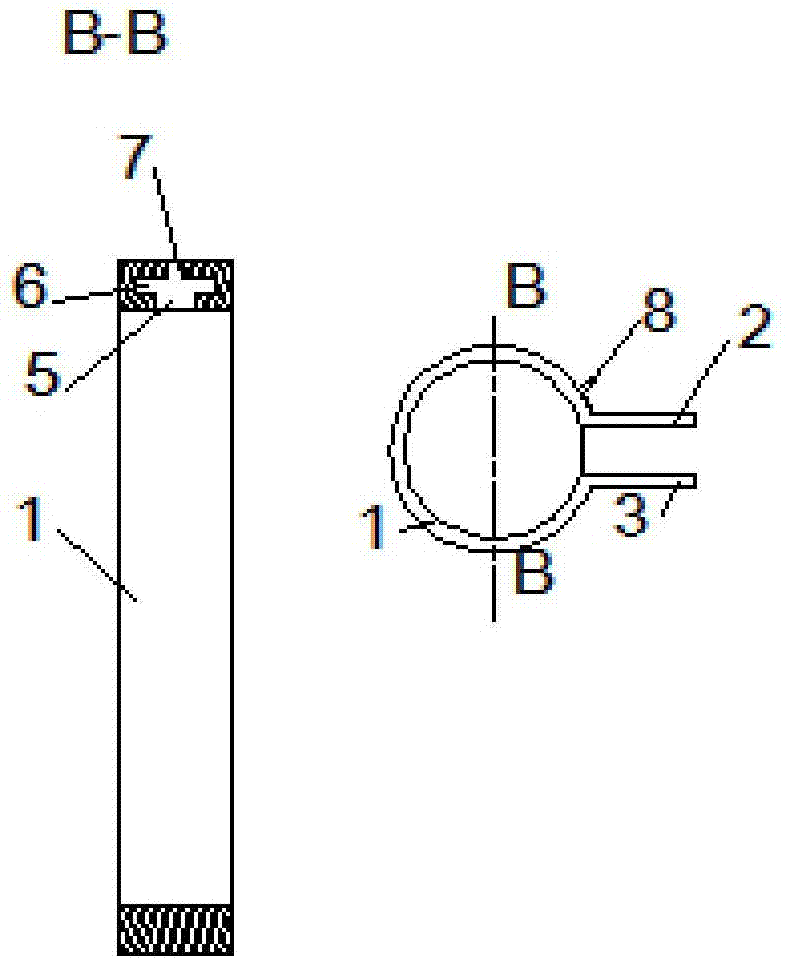

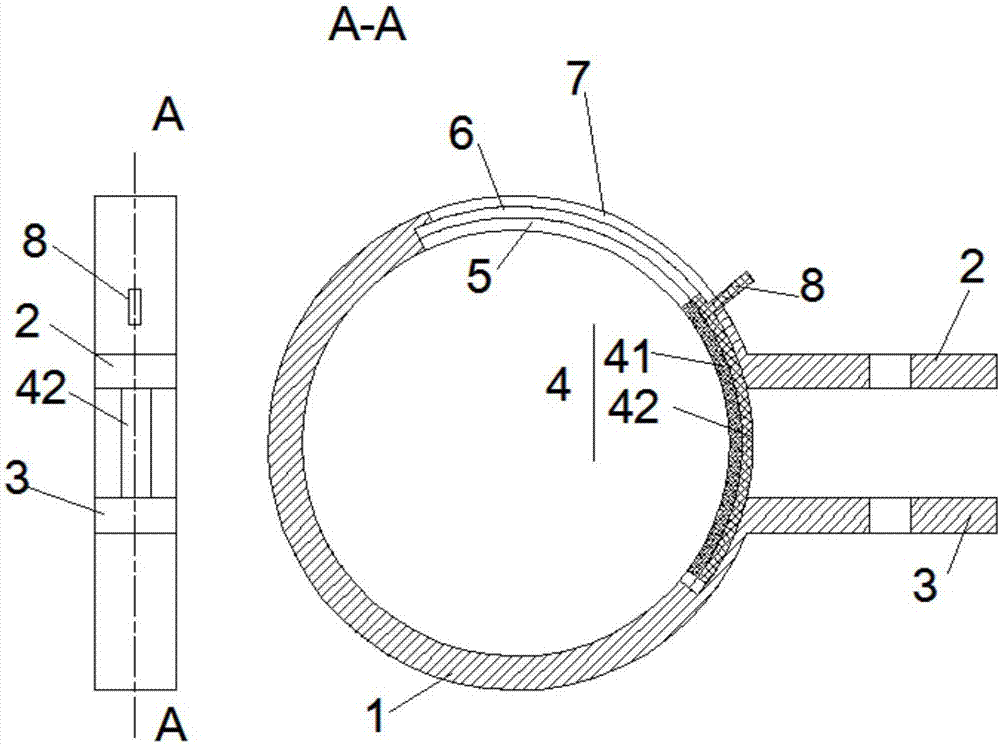

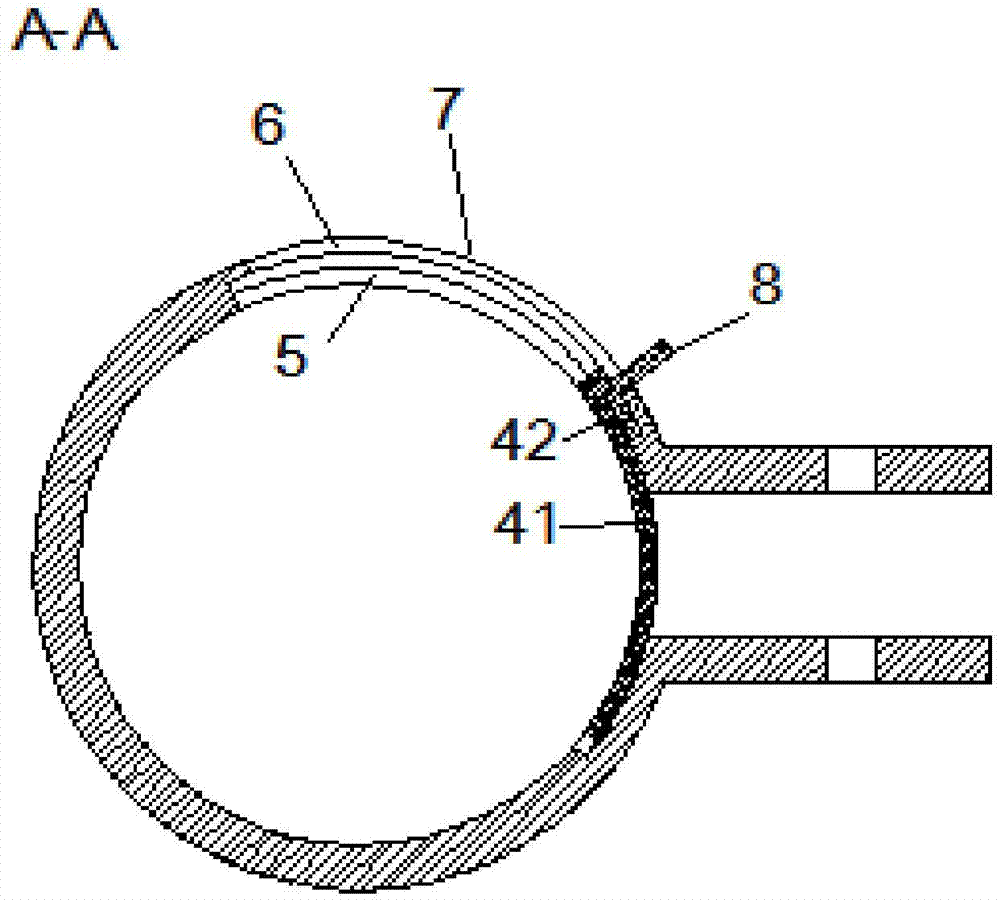

[0020] refer to figure 1 , figure 2 , a joint fastener for an oil cooler proposed by the present invention includes: a hoop 1 , a first pressure plate 2 , a second pressure plate 3 and a seal 4 .

[0021] The hoop 1 is an open ring structure, the first pressure plate 2 and the second pressure plate 3 are respectively connected to the first end and the second end of the hoop 1 and are located outside the hoop 1, the first pressure plate 2 and the second pressure plate 3 are parallel to each other, The first pressing plate 2 and the second pressing plate 3 are respectively provided with perforations, and the positions of the perforations are corresponding. When the hoop 1 is set on the position that needs to be tightened, such as the joint between the oil cooler and the oil tank, the first pressure plate 2 and the second pressure plate 3 can be locked by bolts, and the joint can be pressed tightly through the hoop 1 .

[0022] The inner wall of the hoop 1 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com