Digital embroidered cloth printing method capable of realizing intelligent visual guidance

A technology of digital printing and intelligent vision, applied in the field of digital printing of embroidery cloth, can solve the problems of high positioning requirements, texture distortion, narrow distance, etc., and achieve the effect of accurate and error-free pattern printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

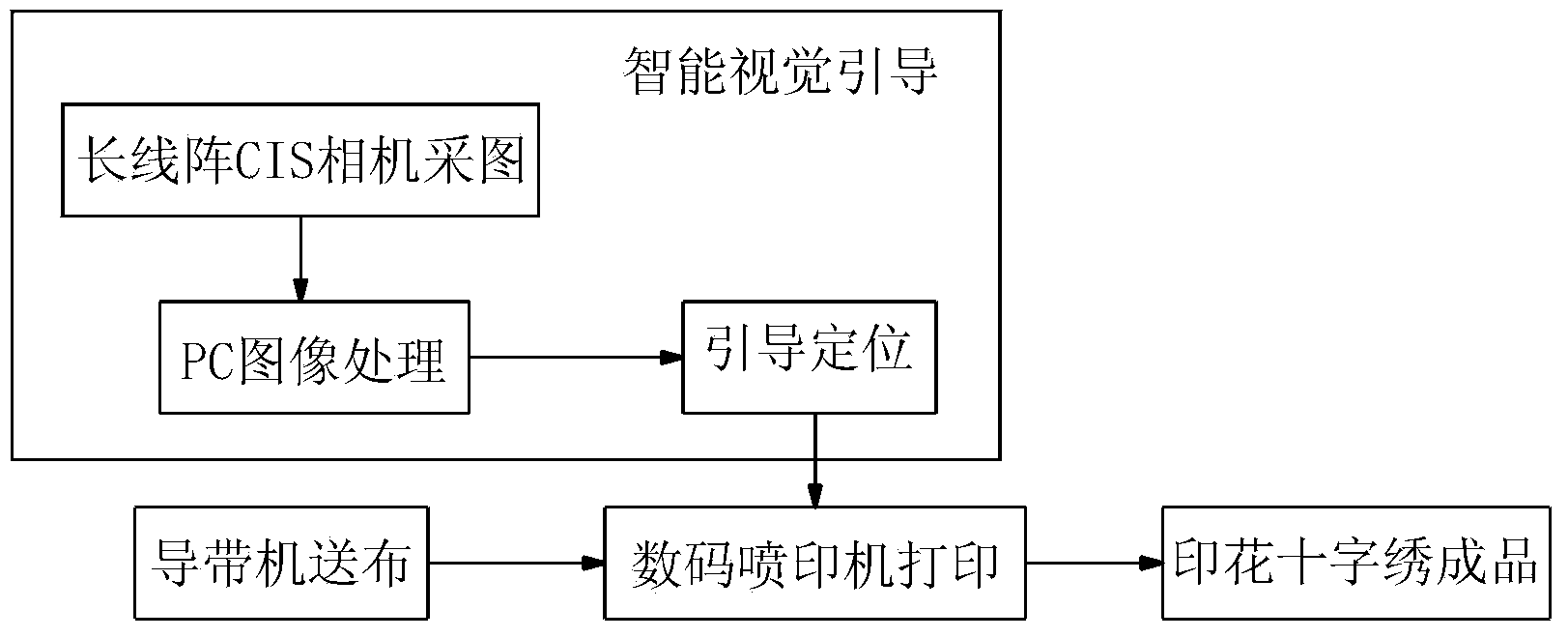

[0021] Example 1: see figure 1 , a digital printing method for embroidered cloth that can realize intelligent visual guidance, the embroidered cloth is a cross-stitched cloth, and the specific steps are as follows,

[0022] a. Adjust the speed of the tape guide machine to match the printer, set the length of the cloth output within a certain period of time, and transport the embroidered cloth to be printed to the digital printing area and stop;

[0023] The speed of the tape guide machine and the number of turns per rotation can only be adjusted once before the entire roll of embroidered cloth starts to print, and the speed is related to the image acquisition module, the width of the printing width and the mechanical position structure of the nozzle. Pre-set various conventional parameters such as rotational speed and number of rotations, and select directly. In the subsequent printing process, after printing a section of embroidered cloth, the subsequent embroidered cloth wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com