Constant-pressure drilling system of top drive drill winch and working method thereof

A drilling rig and top drive technology, which is applied in the field of geological drilling engineering, can solve problems such as low efficiency, slow feeding speed in drilling soft formations, and damage to drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

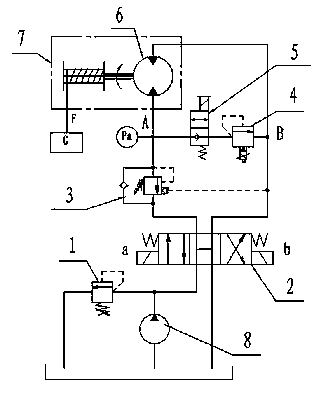

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings. As a preferred embodiment of the present invention, please refer to figure 1 , a top drive drilling rig winch constant pressure drilling system has a hydraulic pump station, the hydraulic pump station includes a hydraulic pump 8, a manual reversing valve 2 and a drilling rig winch 7 driven by a winch motor 6. The hoist motor 6, the hydraulic pump 8, and the manual reversing valve 2 form a hydraulic oil circulation circuit through the hydraulic pipeline, and the manual reversing valve 2 is used to adjust the running direction of the hydraulic oil in the hoisting motor 6. A branch connected in parallel with the winch motor 6 is arranged on the hydraulic pipeline, and an electromagnetic cut-off valve 5 and a proportional overflow valve 4 are arranged in series on the branch. The input end of the winch mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com