Heavy rare earth and light rare earth separation method and extraction agent

A separation method, light rare earth technology, applied in the direction of improving process efficiency, etc., can solve the problems of long extraction equilibrium time, low separation efficiency, poor selectivity, etc., to achieve slow extraction kinetics, high extraction efficiency, and strong specificity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

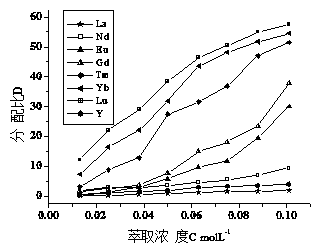

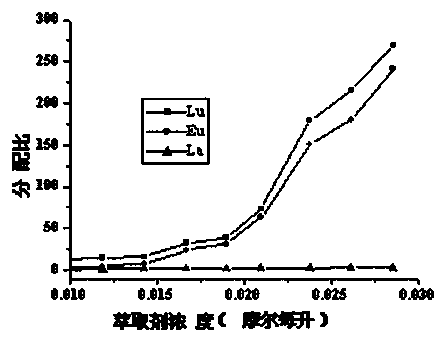

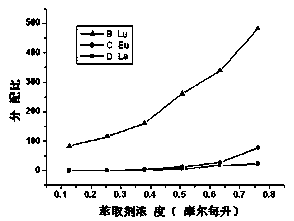

Image

Examples

Embodiment Construction

[0035] The extractant 1-methylimidazole or 2-methylimidazole specifically used in the present invention can be obtained commercially. In the imidazolium-based ionic liquid used in the related experiments of the present invention, the anion is hexachlorophosphate or ditrifluoromethylsulfonamide, and the substituents on the imidazole ring of the cation can be changed.

[0036] The results of some specific experiments are provided below:

[0037] Ionic liquid preparation example

[0038] The imidazole ionic liquid used in each embodiment described later is 1-methylimidazole bistrifluoromethanesulfonamide shown in formula 3, which can be obtained commercially, and can also be synthesized by the reaction of formula 4

[0039]

[0040] Preparation, reference can be made to the preparation of ionic liquids ( Solvent Extr. Ion Exch. , 2006, 24, 19-31). An example of the preparation of an ionic liquid is provided below:

[0041] In a 250mL three-necked flask, add equimolar 1-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com