Open guard railing

A kind of guardrail and open technology, applied in the field of mobile guardrail, can solve the problems of high production cost, inability to adapt to the use of trains, and the falling of passengers' bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

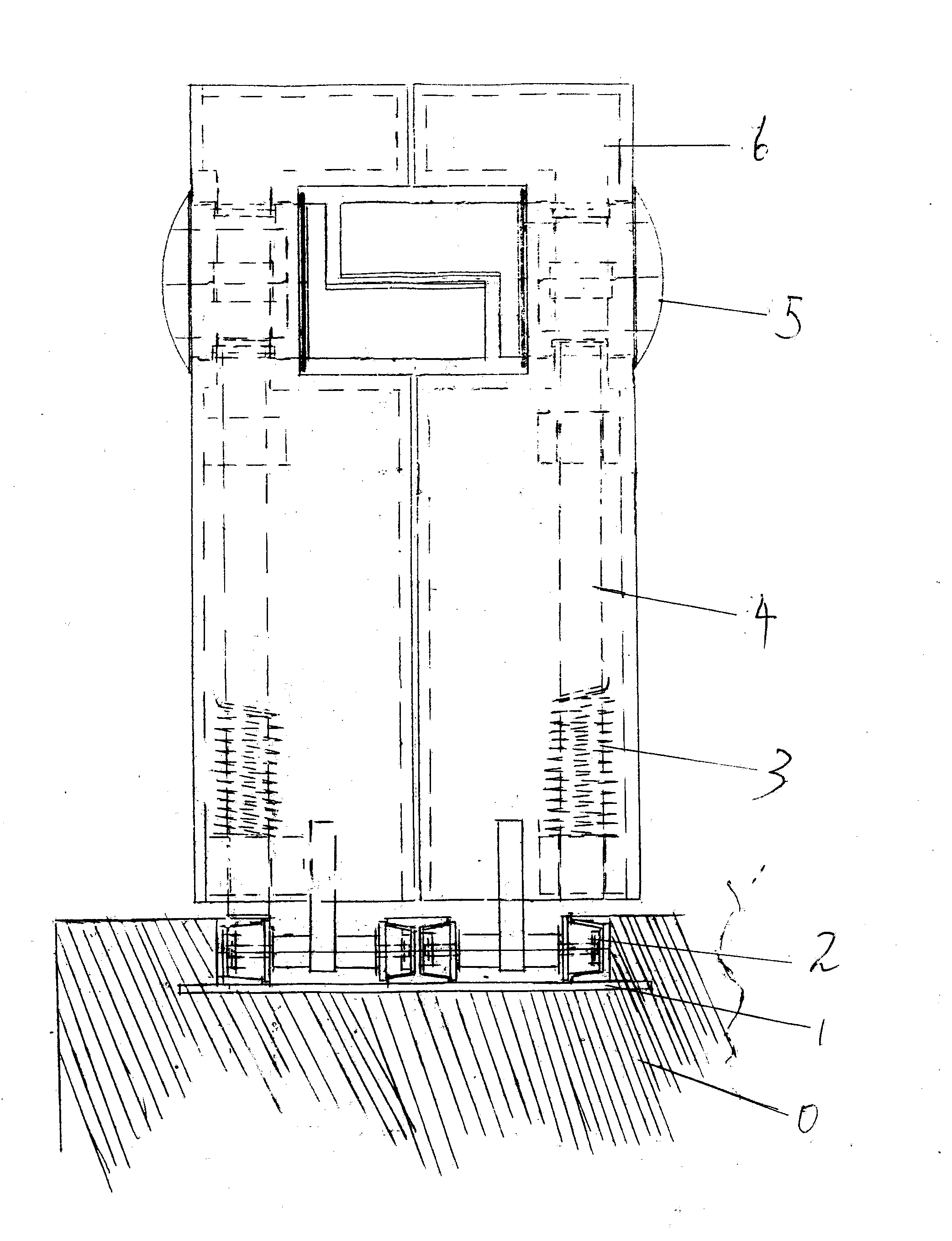

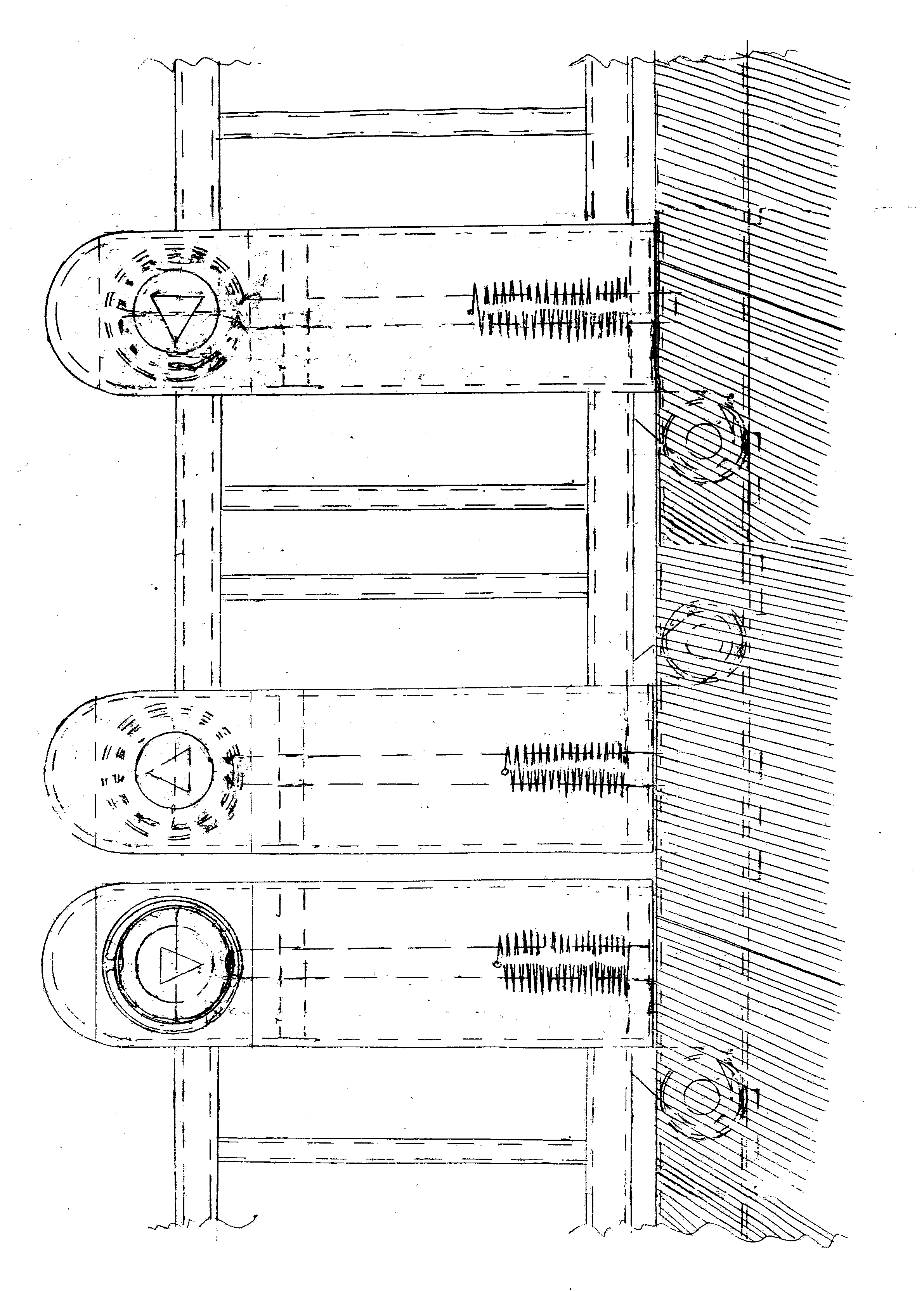

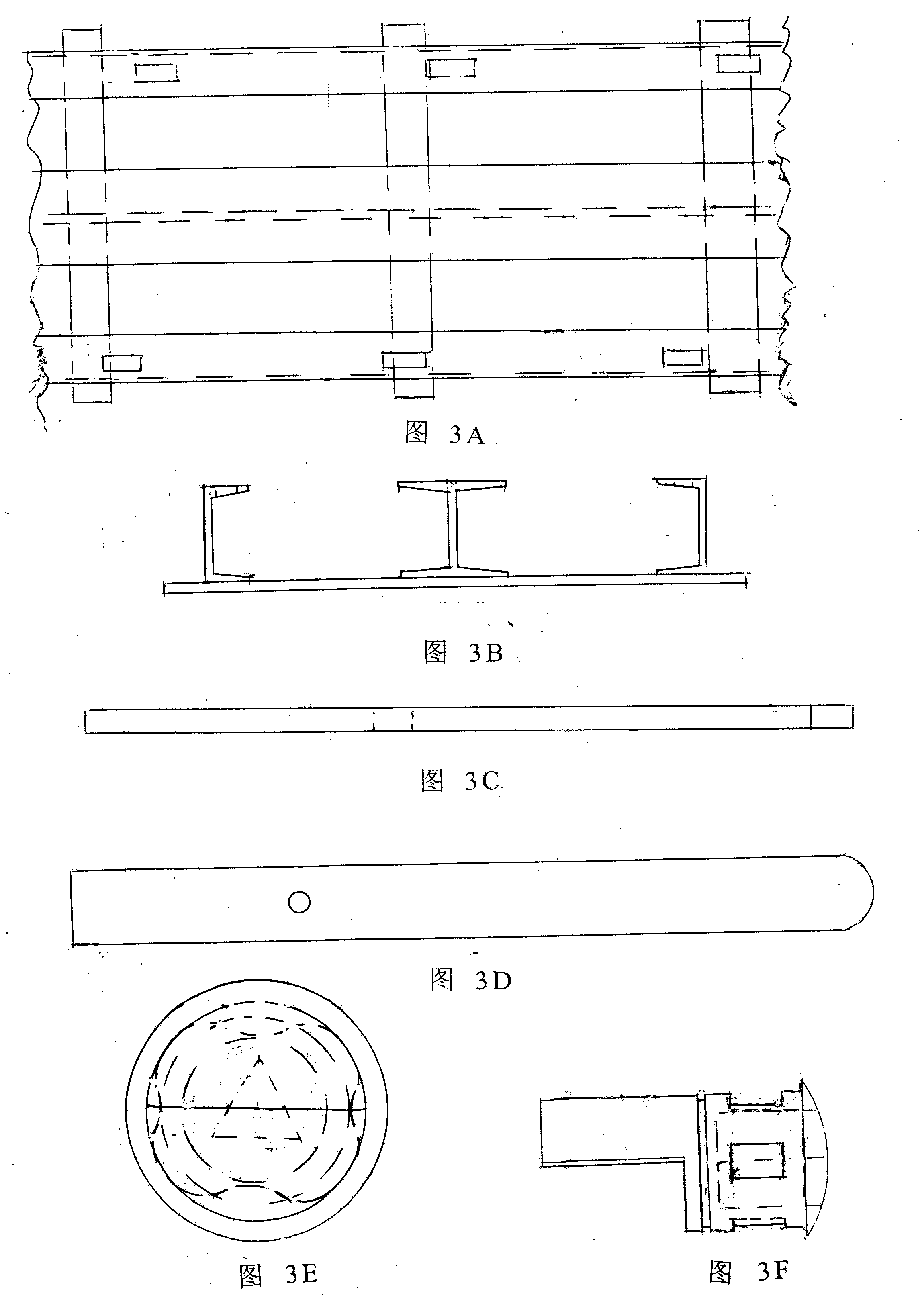

[0013] On the corresponding base surface 0, put the buried rail 1 flat on it as required, then weld and fix it, and finally pour concrete on the left and right sides of the buried rail 1, and lay tiles on the concrete.

[0014] On the fixed shafts on the front and rear sides of the earring-shaped projections below the two tops of the protective railing 6, respectively, a buried wheel 2 is put on, and then the earrings under the two tops of the protective railing 6 A cotter pin is respectively inserted into the thin holes on the fixed shafts on the front and back sides of the protrusion and sealed.

[0015] After the upper end of the positioning rod 4 is strung in from the bottom to the upper end of the lower end nozzle of the two longitudinal tubular bodies at the left and right ends of the protective railing 6, the spring 3 is placed on the bottom of the positioning rod 4. Outside, then the upper end of the positioning rod 4 is strung up into the aperture of the upper end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap