Lockable ejection device with overload mechanism

A technology that pushes out the device and closes the position. It is applied in the direction of household appliances, furniture parts, drawers, etc., and can solve problems such as undesired unlocking and channel widening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

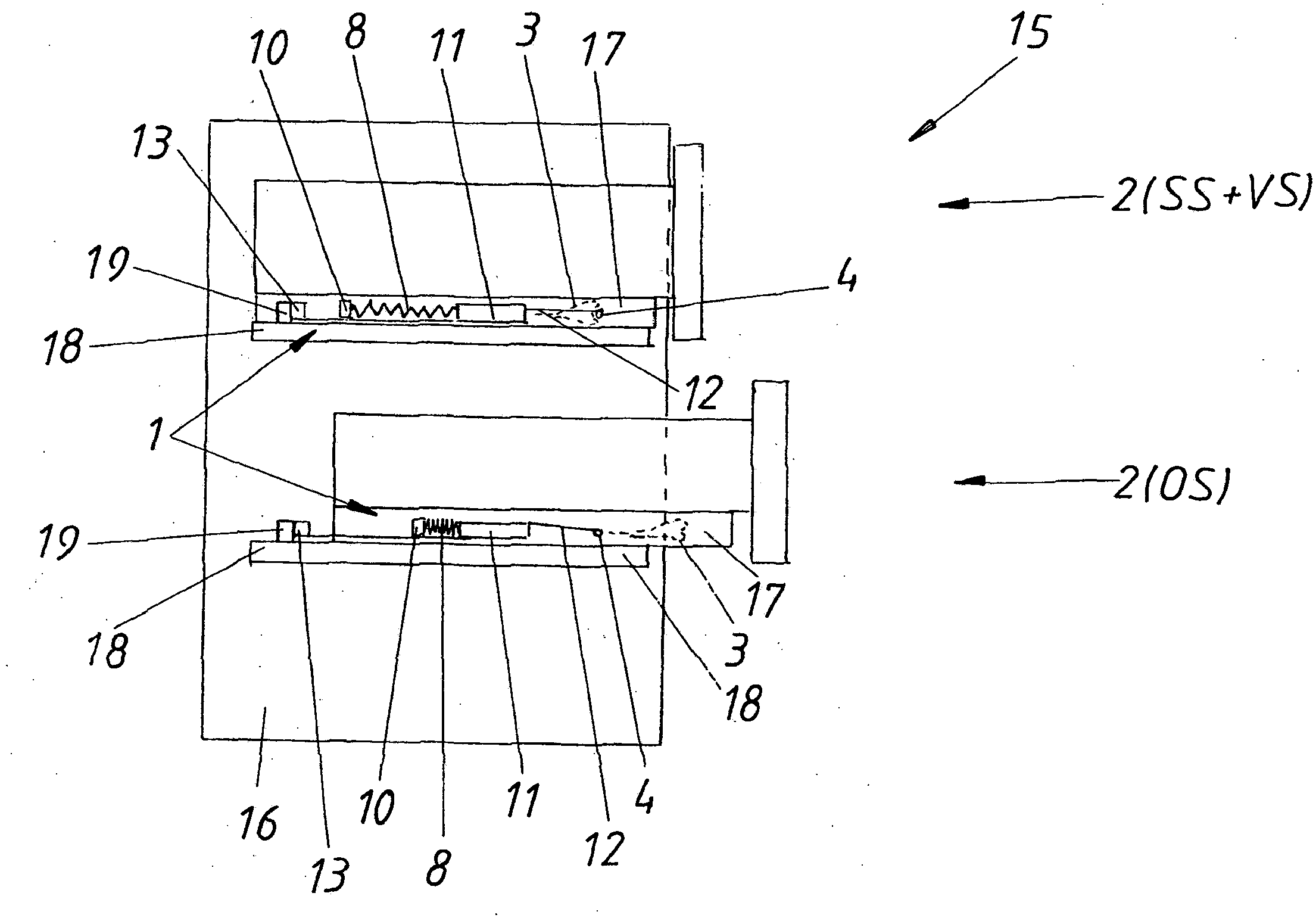

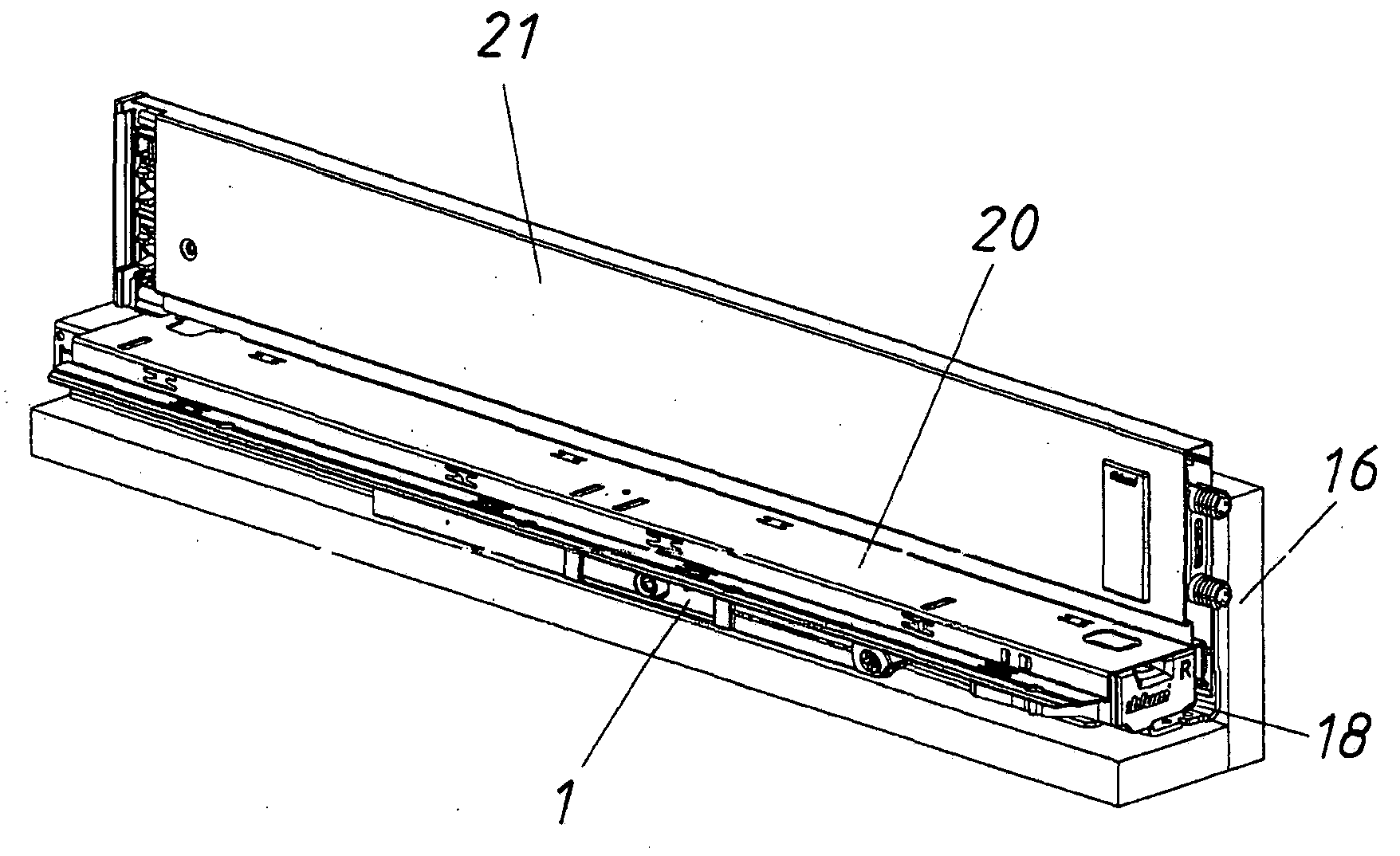

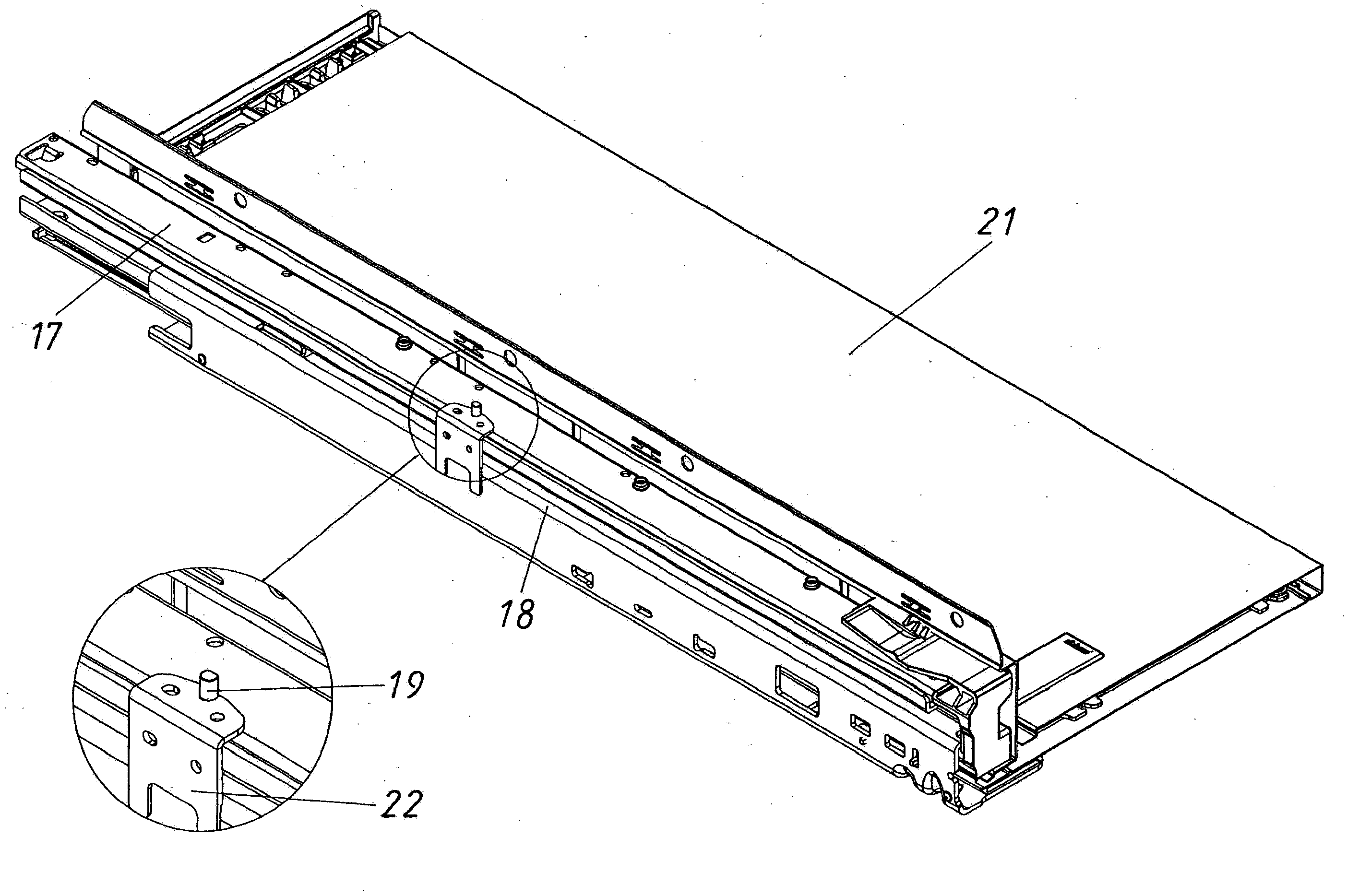

[0032] figure 1 A piece of furniture 15 is shown, which comprises a furniture body 16 and two movable furniture parts 2 . In this case, the upper movable furniture part 2 is in the closed position SS, wherein the control bolt 4 is held in the locked position VS in the slideway 3 . The control pin 4 is connected via a control rod 12 to a slide 11 which is displaceable in a housing 10 (shown only schematically here). The carriage 11 is connected to the housing 10 via an ejection spring 8 , wherein the ejection spring 8 (tension spring) is tensioned in the locked position VS. The ejection device 1 is mounted on the drawer rail 17, wherein the drawer rail 17 is locked relative to the main body rail 18, i.e. cannot be moved, since the drawer rail 17 is held on the main body by the ejection device 1 and its ejection element 13 (with locking hooks) On the driving part 19 of the guide rail 18.

[0033] If now (as in figure 1 (shown in the lower movable furniture part 2 ) (possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com