A laser processing method

A laser processing method and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to mark and difficult to achieve, and achieve the effect of laser welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

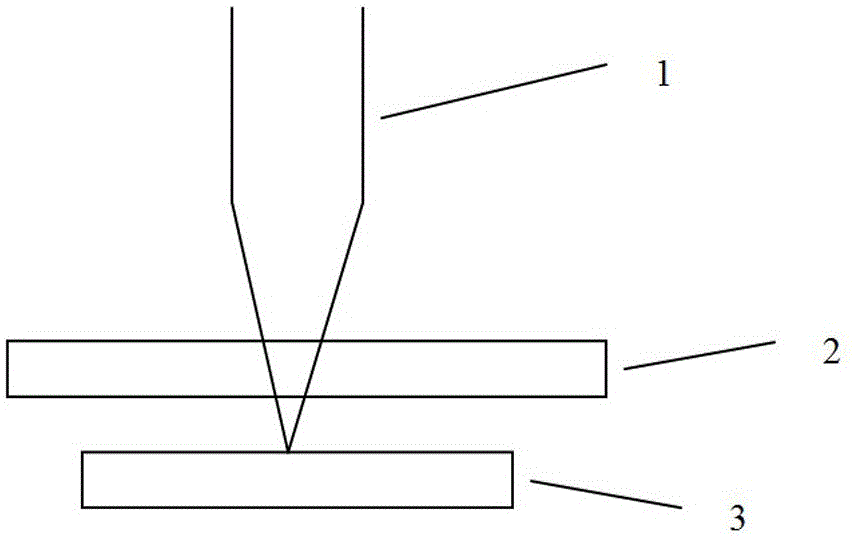

[0025] Embodiment one: see attached figure 1 As shown, a laser processing method uses a transparent or translucent packaging layer 2 to shield the material 3 to be processed, the packaging layer 2 and the material 3 to be processed are separately arranged, and the laser beam 1 is focused on the material to be processed through the packaging layer 2 Laser processing is performed on the processed material 3, and the wavelength of the laser beam is 1.5 microns to 4 microns.

[0026] The packaging layer 2 is transparent or translucent glass material, plastic material, crystal material or semiconductor material, used for packaging, protection and other purposes. The material 3 to be processed is a laser processed organic matter-containing material containing >50% organic matter.

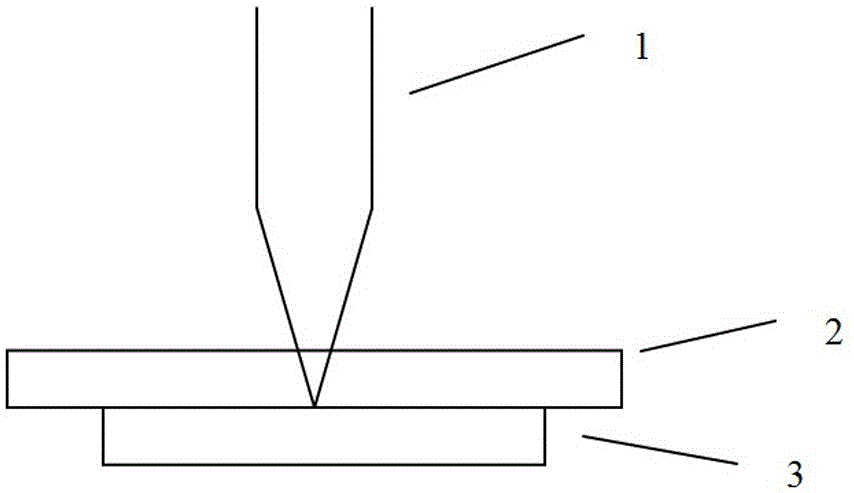

[0027] The packaging layer 2 and the material 3 to be processed can also be in direct contact, such as figure 2 shown.

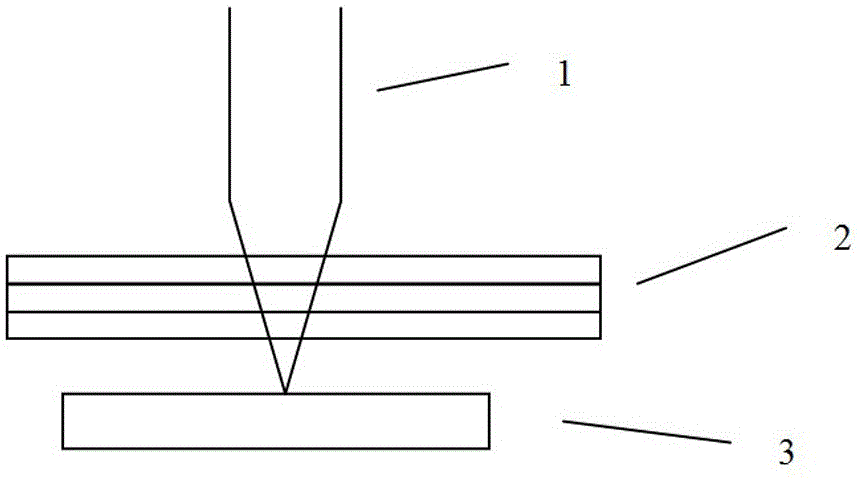

[0028] The packaging layer 2 can be a single-layer material or a multi-layer ma...

Embodiment 2

[0029] Embodiment 2: A marking method for laminated glass, see attached Figure 4 shown.

[0030] High-strength glass, such as bullet-resistant glass, consists of multiple layers of glass connected by bonding materials containing organic substances. as attached Figure 4 As shown, the laminated glass is composed of a first glass layer 4 , a second glass layer 6 and an adhesive material 5 containing an organic substance sandwiched between the first glass layer 4 and the second glass layer 6 . The bonding material is usually colorless and has good transmission at 1 micron wavelength. However, the adhesive material containing organic substances has absorption near 2 microns due to the C-H bond. In this embodiment, the laser beam 1 with a wavelength of 1.8 microns to 2.2 microns is used for marking. The laser beam is focused on the adhesive material 5 containing organic substances to realize marking. The mark is in the middle of the laminated glass, which is extremely difficul...

Embodiment 3

[0031] Embodiment three: see attached Figure 5 As shown, marking of organic-containing materials in one-layer plastic packaging. Organic materials have better permeability near 1 micron, so lasers near 1 micron cannot be used for marking. For example, a 1 micron Q-switched laser is difficult to effectively mark on transparent plastics. But it can be marked with a 2 micron laser. Although the packaging material may also have some absorption around 2 microns, the laser is focused on the object being marked. Because the laser energy per unit area on the packaging material is small, no marks will be left on the packaging material. This marking method is very useful in industrial production, especially on objects of relatively small size. Marking can be done after packaging. Very effective and reduces production costs. It is also very useful in pharmaceutical products. Because laser marking does not require any other substances, it is safe and reliable. Figure 5 The packa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com