Belt conveyor centralized control method and system

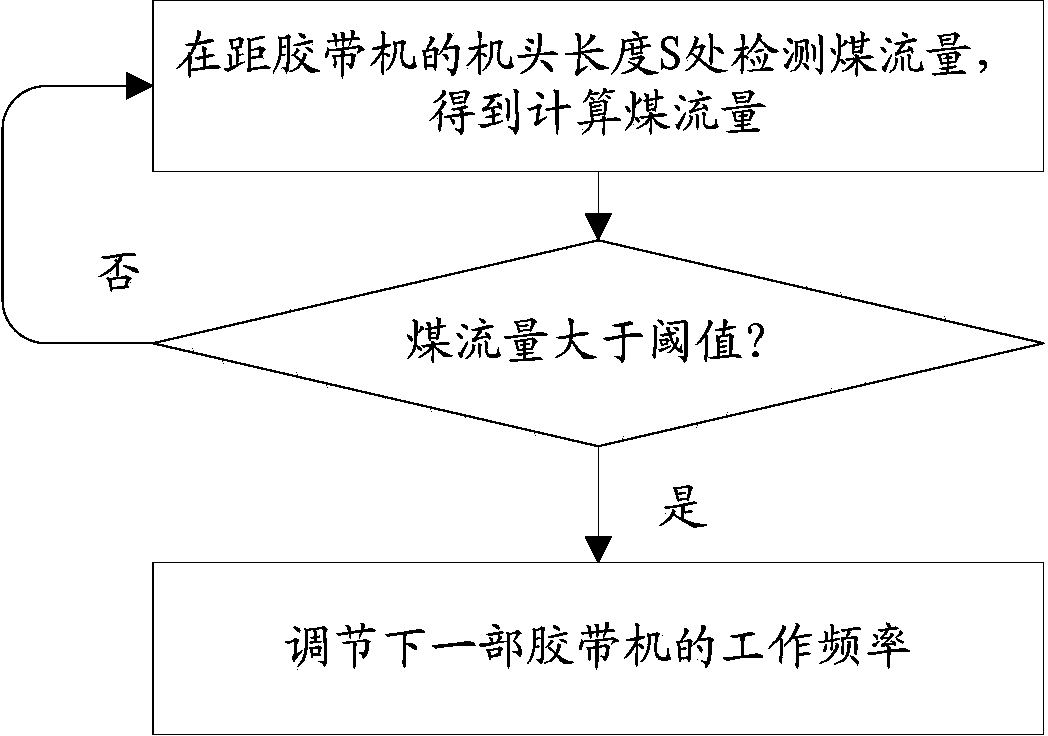

A centralized control system and belt conveyor technology, applied in the centralized control method and system field of belt conveyors, can solve problems such as buried pressure, failure to realize frequency conversion operation of belt conveyors, and inability to truly reflect the coal flow rate of belt conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

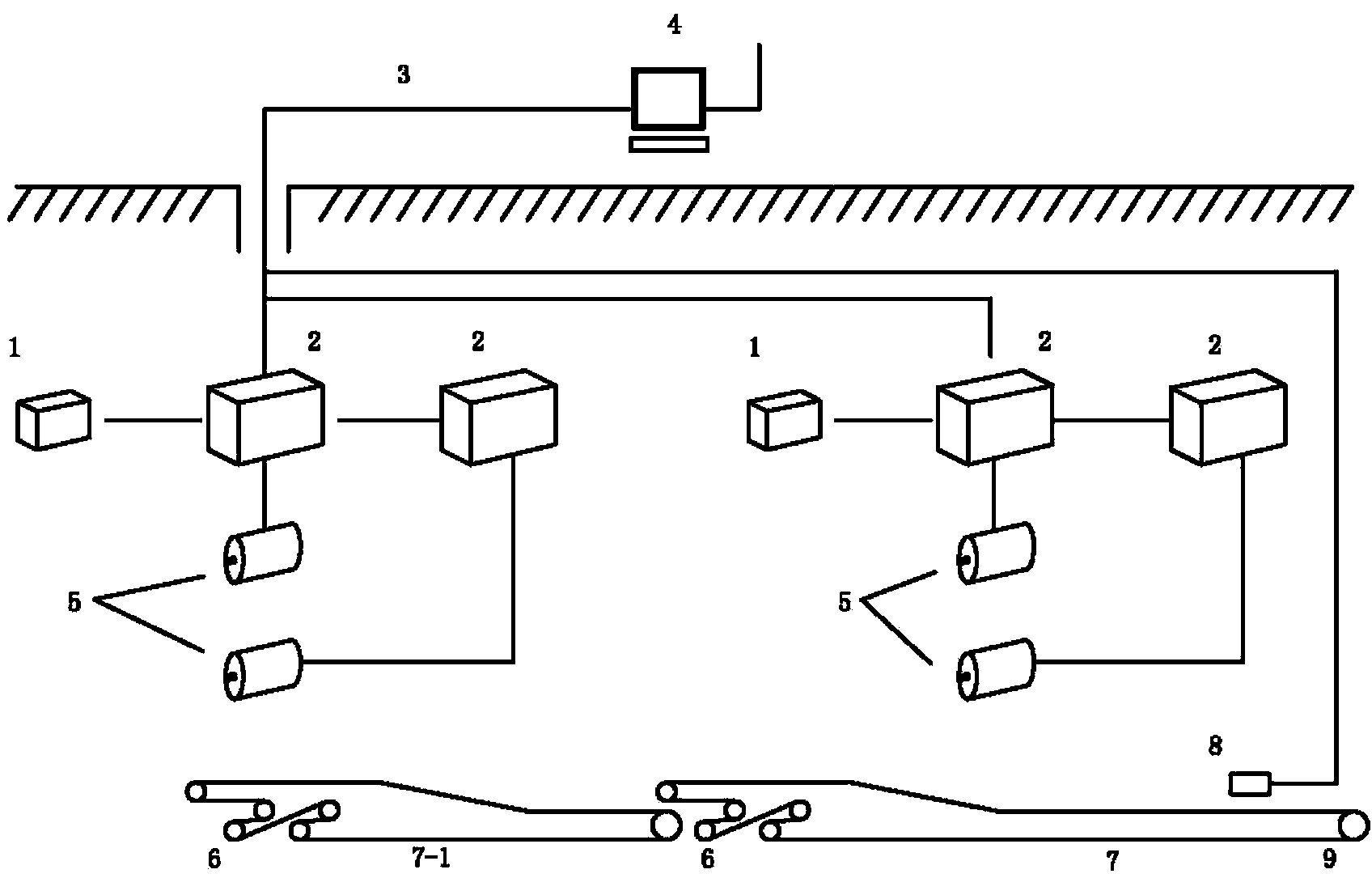

[0020] As shown in 1, the tape machine is driven by the traction motor 5, and the power of the traction motor 5 determines the running speed of the tape machine. The traction motor 5 is electrically connected to the frequency converter 2 , and the frequency converter 2 controls the working frequency of the traction motor 5 . The frequency converter 2 can be controlled by the technician at the console 1 locally, more advantageously, controlled by the ground control device 4 . The frequency converter 2 communicates with the ground control device 4 through an optical cable 3 .

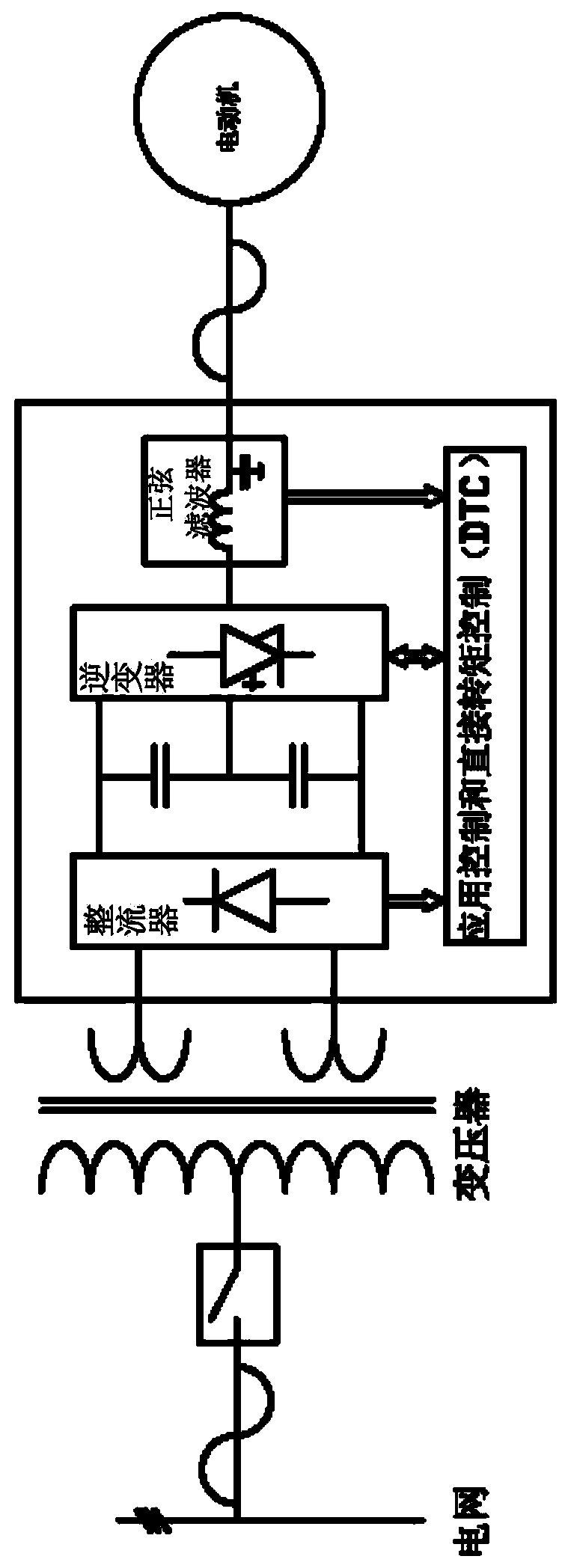

[0021] figure 2 shown figure 1 Inverter 2 structure and principle of frequency conversion. The frequency converter 2 is a power control device that converts the commercial frequency power supply to another frequency by using the on-off function of the power semiconductor device. A device that transforms the power frequency power supply (50Hz or 60Hz) into AC power supplies of various frequencies thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com