Rubber belt conveyor coal position protection system of mine sieving system

A belt conveyor and protection system technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of clogging the coal chute and burying the machine head, so as to prevent the burial, save time and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

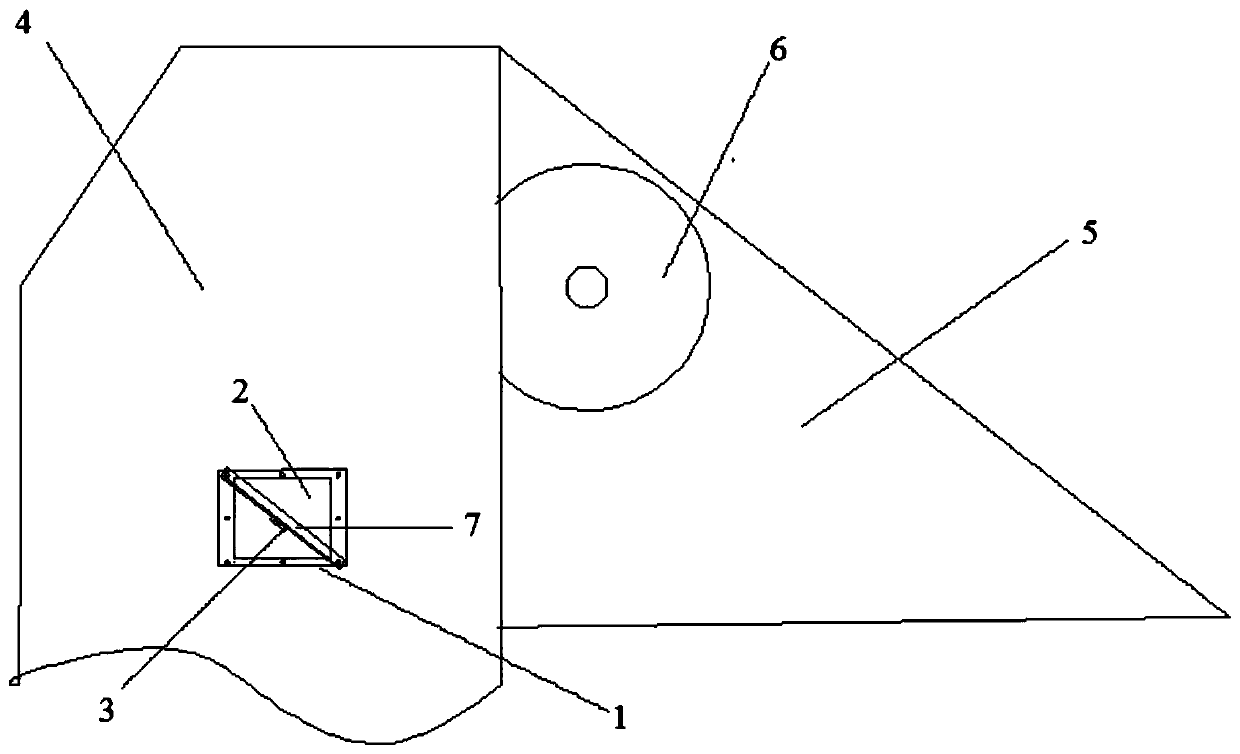

[0030] Open a 250×300mm square hole at the appropriate position of the coal chute 4, install a piece of 300×400mm adhesive tape, and then install an AZ-7121 travel switch 3, and electrically connect the travel switch 3 to the belt conveyor 5 coal level switch .

[0031] After the transformation was completed on January 20, 2016, the accident that the head 6 of the belt machine was often buried and the difficulty of dredging the coal chute 4 were completely solved, the production efficiency was greatly improved, the operation safety of the belt machine was ensured, and the extension the service life of the equipment. Reduce the labor intensity of employees and improve production efficiency. In the half a year after the transformation, there was no accident that the head 6 of the tape machine was buried in the screening system, directly saving more than 50 hours. 500 tons of raw coal are selected per hour, and the price of each ton of raw coal is 150 yuan, directly creating mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com