Sound insulation wall of anechoic chamber

An anechoic chamber and wall technology, which is applied in the direction of indoor acoustics, building components, building insulation materials, etc., can solve the problems of sound leakage, inappropriateness, and the combination of components is not too tight, and achieves leakage prevention, reliable installation, and sealing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

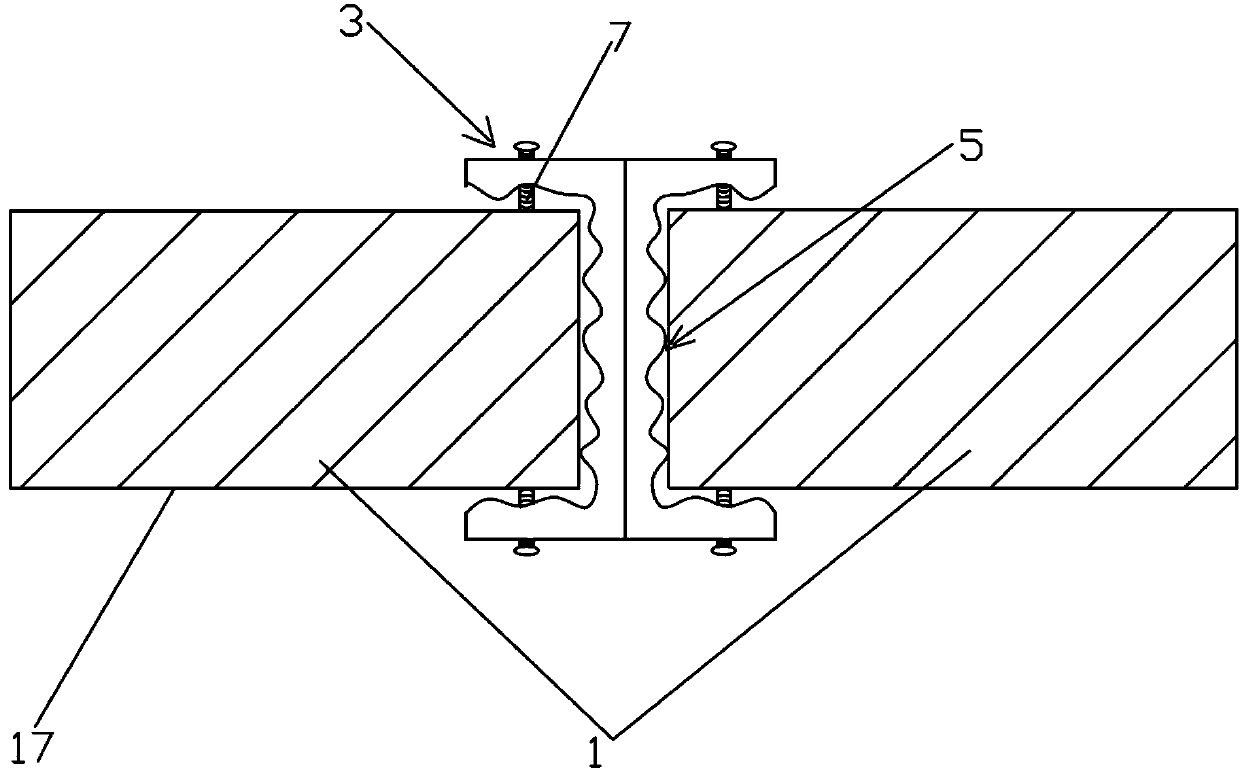

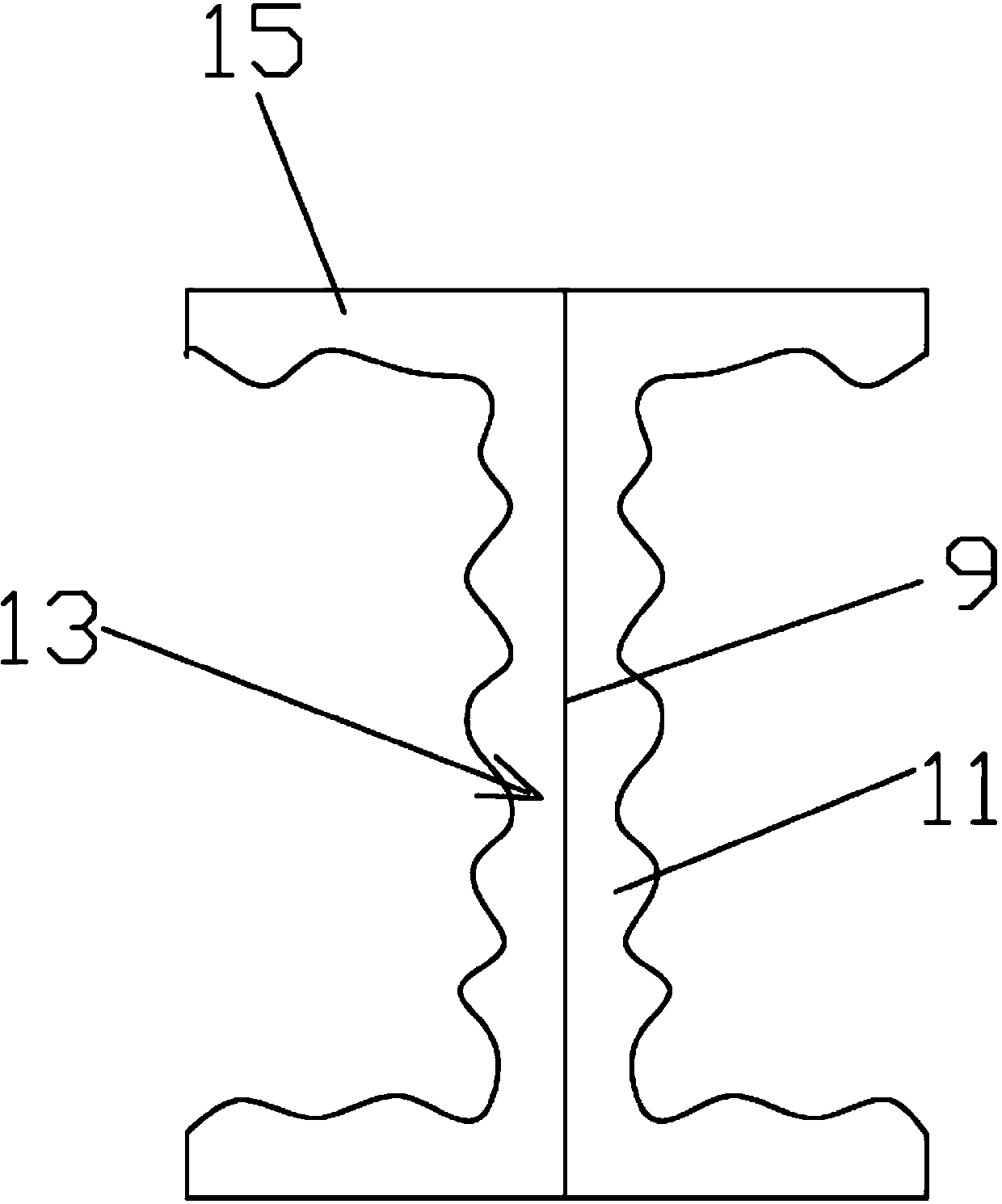

[0022] refer to figure 1 and figure 2 , a sound insulation wall of an anechoic room or anechoic box, comprising a plurality of sound insulation wall modules 1 and a sealing device 3 arranged between two adjacent sound insulation wall modules 1 . The sealing device 3 comprises a seal 5 and a fastener 7 . The sealing member 5 is generally made of a skeleton 9 and a soft material 11 fitted on the skeleton 9 ; and according to the assembly function, the sealing member 5 can be divided into a filling part 13 and a pressing part 15 . The frame 9 is made of rigid material, and the soft material 11 can be rubber or other similar materials. The soft material 11 is attached to the opposite sides of the filling part 13 and the inner side of the pressing part 15 close to the sound insulation wall module 1, so that the soft material 11 can be closely matched with the sound insulation wall module 1 . The filling portion 13 is filled between two adjacent sound insulation wall modules 1 ...

Embodiment 2

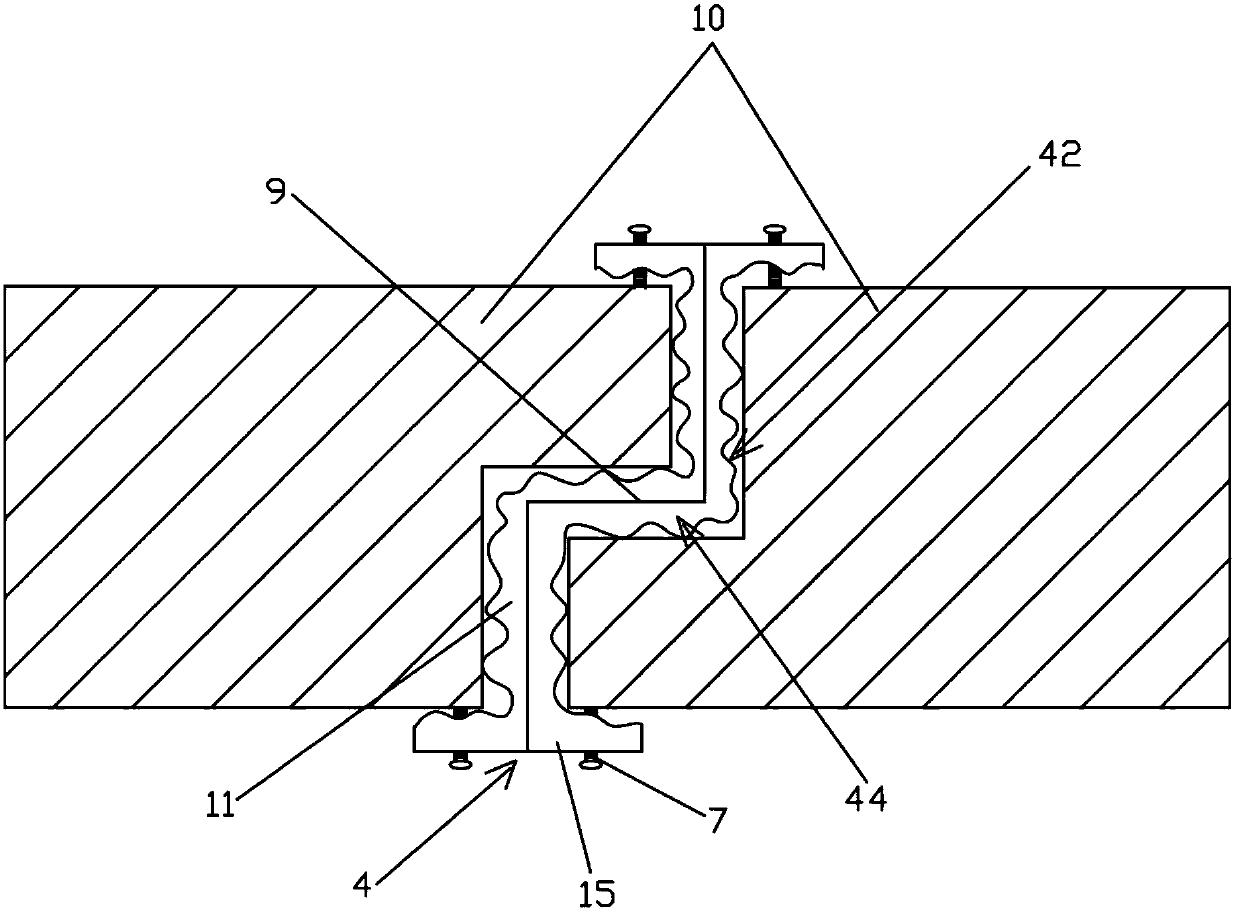

[0024] Compared with the first embodiment, the sealing device 4 of the sound insulation wall of this embodiment is only different in the shape of the sealing member 42, and the other components are the same, so it will not be repeated. The difference is specifically, that is, according to the zigzag shape requirement of another sound insulation wall module 10 , the filling part 44 of the sealing member 42 is also arranged in a corresponding zigzag shape. In this way, compared with the linear filling part 13 of the first embodiment, the sound isolation of the filling part 44 should be better.

[0025] It can be seen that compared with the prior art, the sealing device 3 (4) of the sound insulation wall of the anechoic room of the present invention is provided with a sealing member (5, 42) and a fastener 7, and the sealing member (5, 42) has Fill the filling part 13 (44) and the pressing part 15 between two adjacent soundproof wall modules 1 (10), and the soft sealing material 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com