Elastic barrier eliminating device for railway vehicle

A rail vehicle and elastic technology, applied in the field of rail vehicles, can solve the problems of insufficient longitudinal obstacle clearance rigidity and unsatisfactory obstacle clearance effect, and achieve the effects of expanding the scope of obstacle clearance space, ensuring firm and reliable installation, and ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

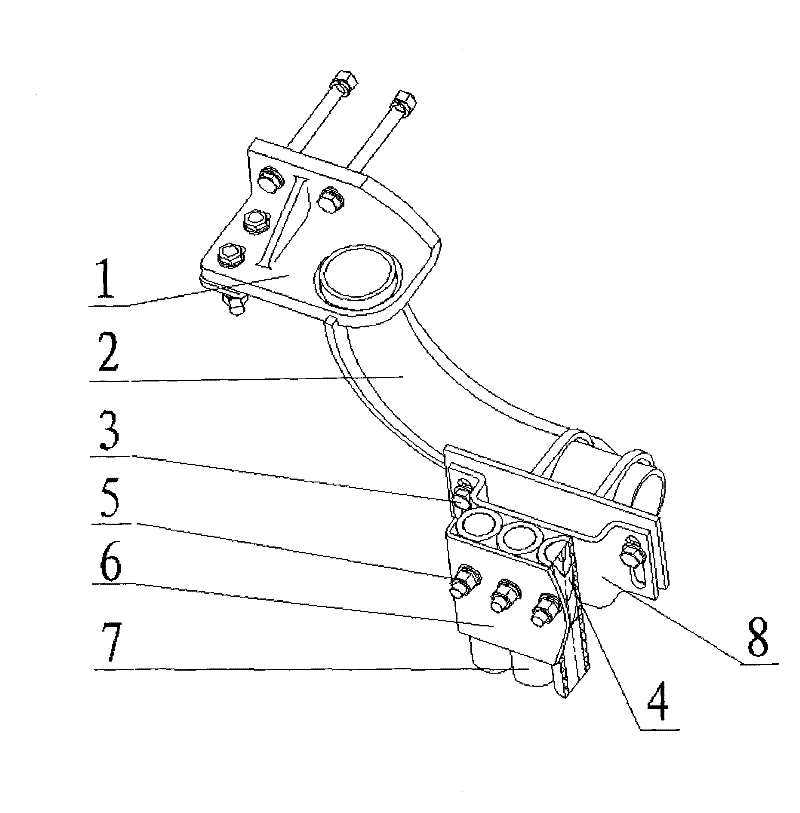

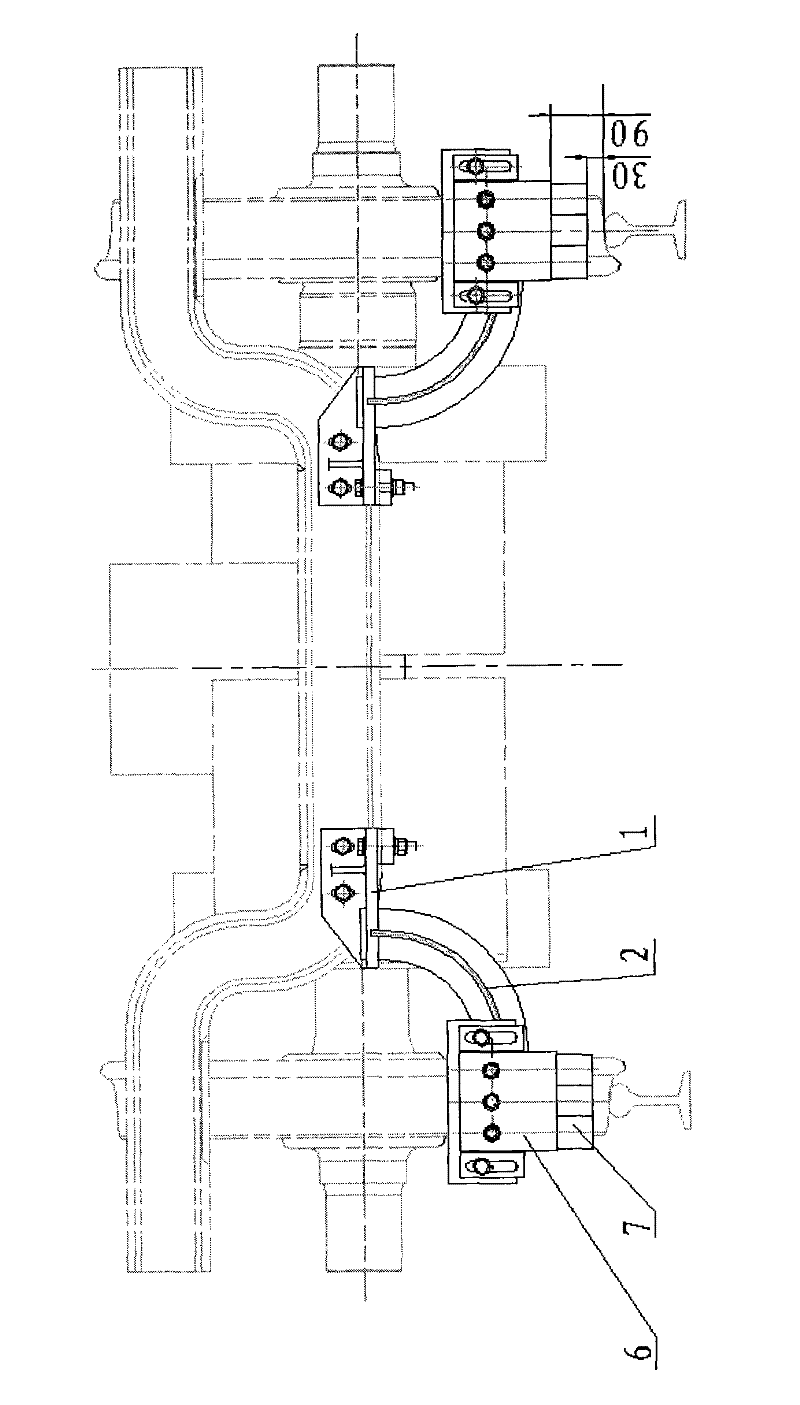

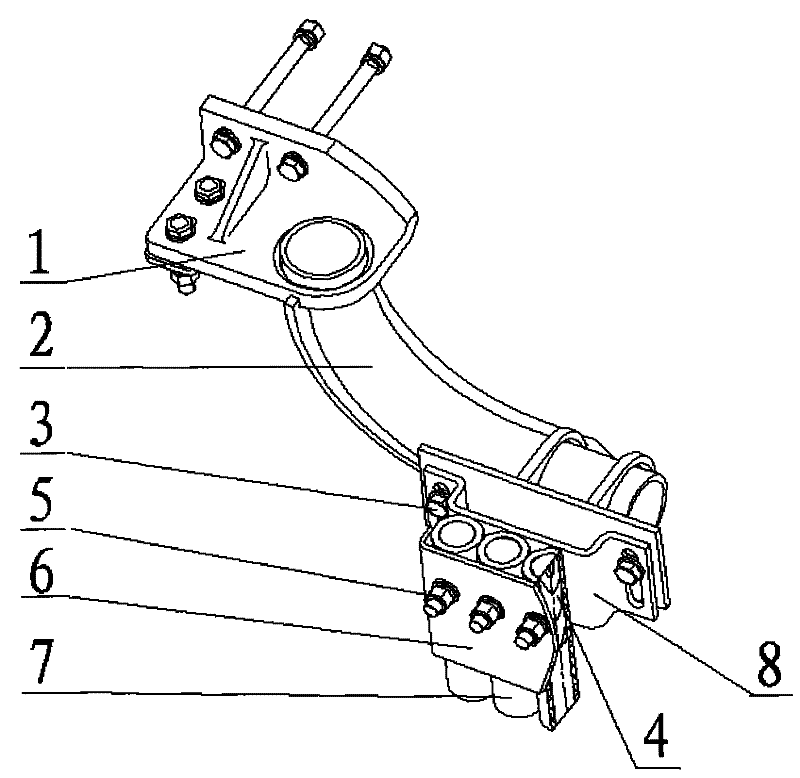

[0008] Referring to the accompanying drawings, the embodiments of the present invention will be described in detail. The frame mounting seat (1) adopts a right-angle structure with triangular ties, and is fixed on the frame of the vehicle bogie by bolts. The bracket (2) adopts a round steel pipe structure with sufficient rigidity and strength, and its upper end is fixed on the frame mounting seat (1). The front and rear pressing plates (6) and (8) adopt a profiled structure. The rear pressing plate (8) is fixed on the lower end of the support (2) by installing the adjusting bolt (3). The upper half of every rubber braided hose (7) is inserted with cork (4). The bolt (5) clamps the upper half of the rubber braided hose (7) between the front and rear pressure plates (6) and (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com