Weaving machine weft yarn tension adjusting device

A technology for weft yarn and loom, applied in the field of weft yarn tension adjustment device of loom, can solve problems such as easy identification, and achieve the effects of reducing end breakage rate, improving production efficiency, uniform and stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

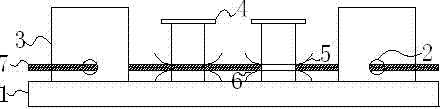

[0012] Such as figure 1 As shown, the present invention includes a base 1, a positioning plate 3 with positioning holes 2, and a number of tension holders 4 that can maintain the tension of the weft yarn 7. The positioning plates are fixed on both sides of the base. The tension maintaining member is fixedly connected to the middle of the base.

[0013] The positioning plate can be arched, rectangular, or triangular. The positioning hole on the positioning plate can be of any shape, as long as the weft can pass smoothly. There are two positioning plates, located on both sides of the base. The positioning plate can be a large One small can also be the same size.

[0014] The tension maintaining member can be a cylindrical stopper or a rotating shaft that can rotate around its own axis. There is mainly sliding friction between the cylindrical stopper and the weft yarn, and the friction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com